The packaging of a luxury jewelry will be mostly characterized as fancy, up-scale, or high quality. That is not merely an aesthetics-based premium feeling as far as manufacturing is concerned. It is the fruit of thoughtful, well-calculated decisions in structure, materials, inserts, finishing procedures and above all, the regularity of quality production.

Most jewelry companies invest in flashy designs and fail to consider the impact of construction, touch, and repeat on the perception of the customer. A quality luxury jewelry package captures the impression of quality consumers at first touch, adding to the perceived value of the jewelry within and doing just as well at maintaining this impression through logistics, showcases in the retail store, and repeated openings.

Premium Jewelry Packaging Starts With Structural Integrity

It all starts with the construction of the box. Any beautifully printed box that bangs out of shape, or folds or bends out of line, becomes instantly unappealing as a symbol of luxury.

Why Rigid Structure Matters for Perceived Quality

Demand High-end jewelry boxes depend on box construction made of rigid material, most readily of thick chipboard or greyboard encased with a specific amount of wrapping to provide stiffness and accuracy. Lids are too close with an excellent magnetic snapper or slow close closure, edges remain sharp, and the overall shape is maintained when subjected to pressure.

Key Structural Elements and Their Impact

| Structural Element | Impact on Perceived Quality |

| Board thickness | Brings bulk and density which conveys luxury. |

| Edge alignment | Creates clean, precise visual lines |

| Lid fit & alignment | Ensures smooth, gap-free opening/closing |

| Compression strength | Maintains shape during shipping & handling |

In our factory experience the structural correctness is usually the first non-conscious notion that the customers make in determining quality even before the logo or foil details come into view.

Materials Influence Weight, Texture, and Perception

How the packaging feels is made directly by the kind of materials you use. Even beautiful designs made on lightweight or weak paperboard may seem cheap.

Selecting Materials for a True Premium Hand-Feel

High-end jewel packaging gives preferences to the use of packing materials that are thicker and heavier paperboard and finer wrapping paper that offers rigidity and a soft, weighty feel. These are not merely looks but they also influence the stability of an assembly and the durability.

Weight and refined texture will be automatically equated by the customers with higher values. An ultra light or overly plastics box is an immediate indication of cost reduction, whereas an object that is well weighted with a place to touch creates an immediate sense of trust.

Inserts Define Both Protection and Presentation

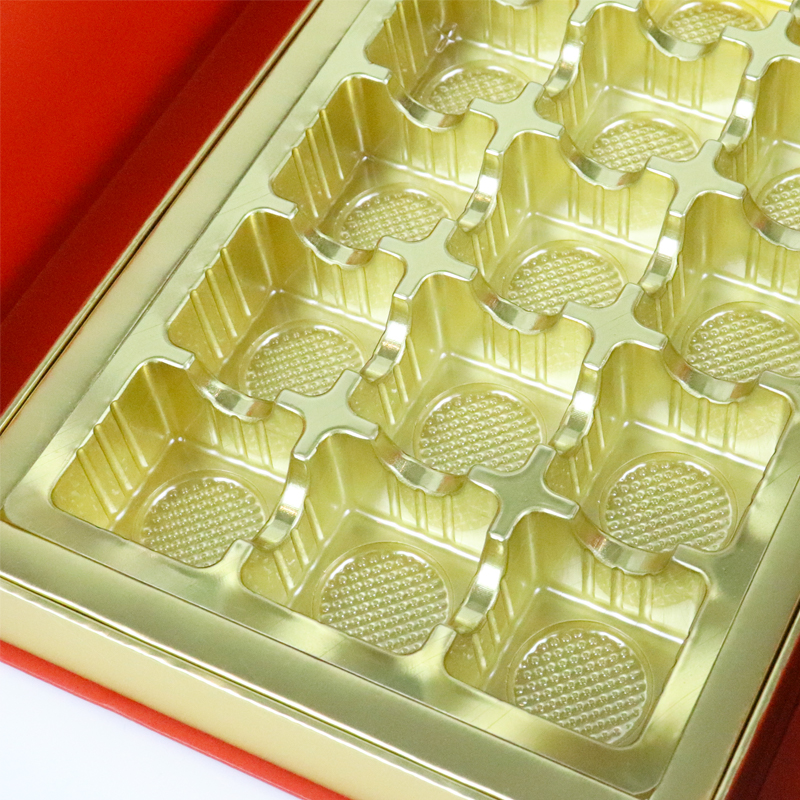

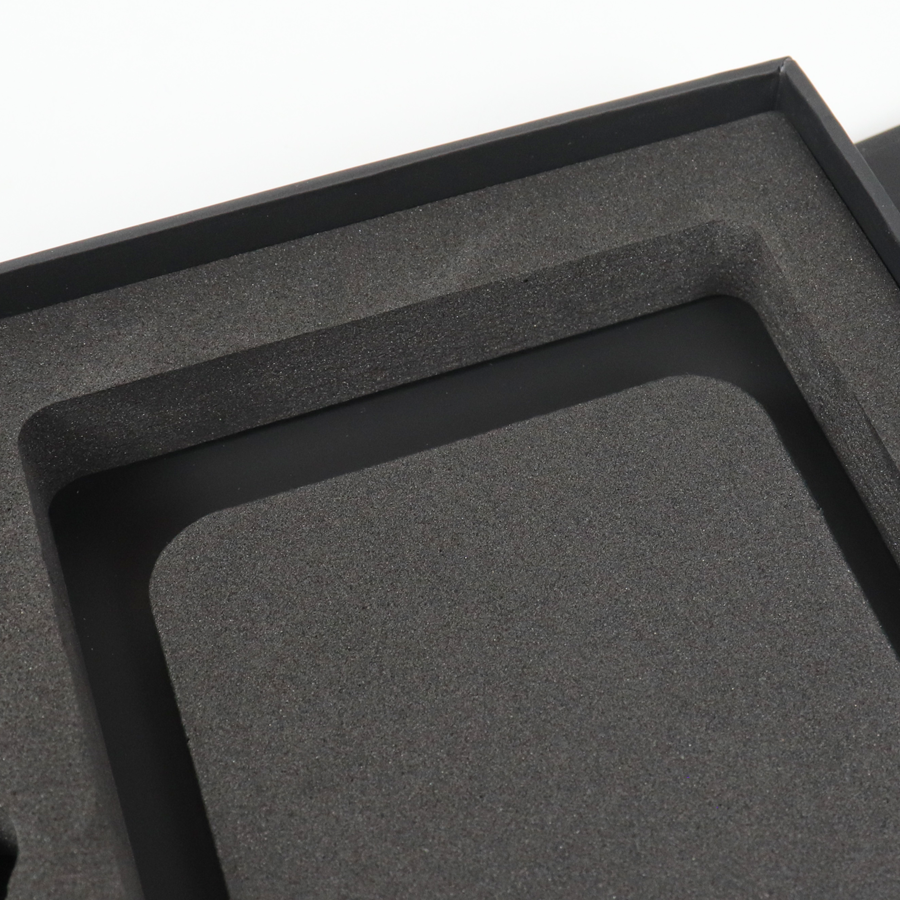

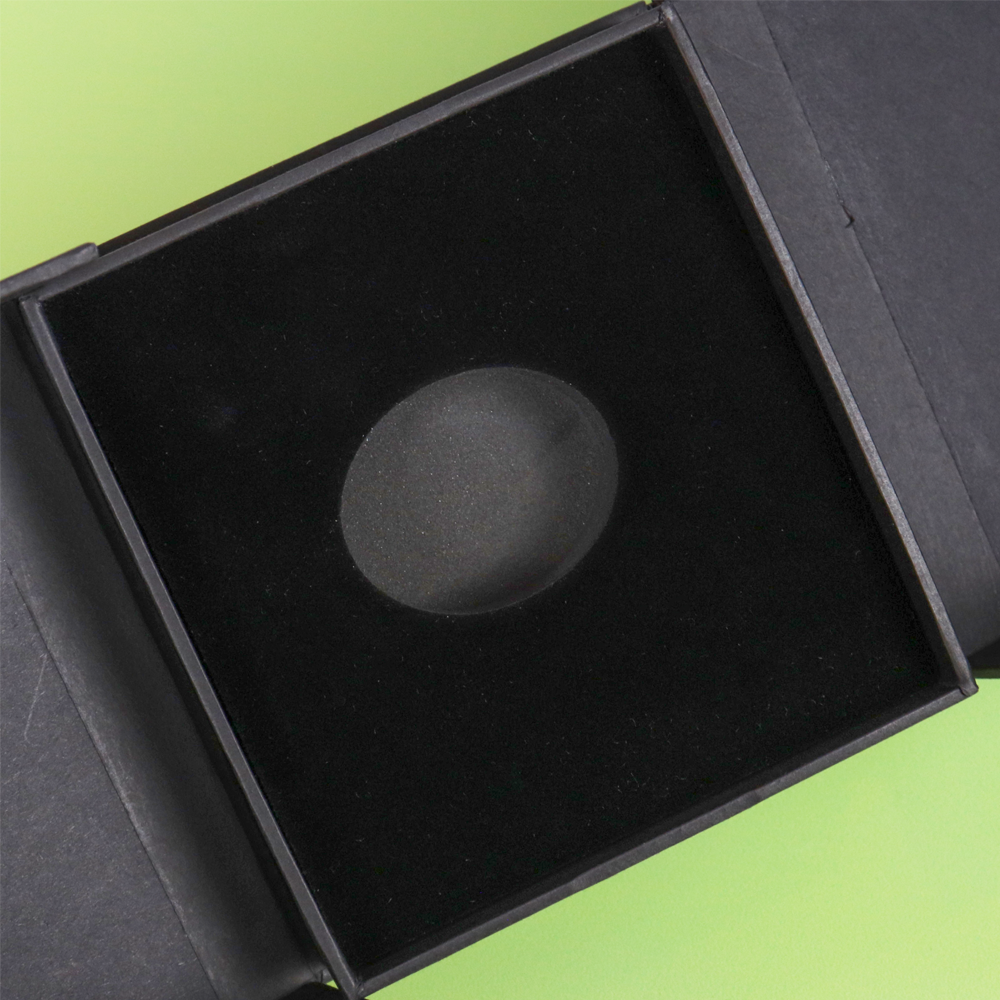

Inserts are not just padding they are used to ensure how the jewelry is displayed, secured and received on unboxing.

Common Insert Types and Their Premium Advantages

| Insert Type | Premium Advantage |

| EVA foam | Firm, durable positioning with clean edges |

| High-density foam | Secure hold with luxurious velvet/suede overlay |

| Paperboard | Structured, minimalist presentation |

| Custom-cut designs | Precision fit that showcases attention to detail |

A badly fitting insert causes pieces to slide or be unease when placed thus compromising craftsmanship. The inserts are engineered well, however, which makes the jewelry look deliberate and stable and enhances the whole experience of unboxing.

Finishing Techniques Communicate Luxury Subtly

The optimal luxury packaging is one that is withheld and not overboard. Little, refined finishing, makes luxury without being obtrusive.

Key Finishing Techniques and Their Signals

| Finishing Technique | Premium Signal |

| Foil stamping | Elegant contrast and metallic refinement |

| Embossing / Debossing | Tactile depth that invites touch |

| Soft-touch lamination | Smooth, velvety modern feel |

| Matte finishes | Understated elegance and sophistication |

Gray areas here are not tolerated. The slight changes in foil positioning or the thickness of the coating may instantly render a run more uneven and inferior.

Weight and Opening Experience Matter More Than Expected

Luxury involves a number of senses. The nice weight of the box, the soft resistance of a magnetic lid, as well as the fluid gentle motif of the way it opens all help in that wow factor.

Too light boxes tend to damage the materials or building design; too willing to snap open results in poor materials and building structure. As compared with it, a curated, weighted opening is one that is meant to be: as though the package itself is an element of the luxury brand.

Manufacturing Consistency Is the Hidden Foundation of Premium Quality

Repeatability is the most neglected feature in jewelry packaging that is considered luxurious. Initial prototypes may be flawless but actual high-quality lasts when used by hundreds or even thousands of items.

It is achieved through this level of uniformity that is made possible by highly-creative in-house processes: die-cutting, printing, multiple levels of QC checks, and years of assembly experience. It is common in brands that change suppliers regularly or which do not have a strong quality system, where alignment, texture, or finishing can vary in a way that creates mistrust.

In the case of jewelry packaging boxes, sample is not the only way, but request the manufacturer to tell you how he can be sure that each batch corresponds to the endorsed variant. At Crown Win Packaging, which is audited by FSC, ISO, BSCI and SGS, the global jewelry brands have this premium feel that they can feel every time they place an order.

Common Misconceptions About “Luxury” Packaging

There are a few myths that drive the brands wrong:

- Ornament is Decorative complexity, As in reality, soberness wins.

- Premium touch is created by images only – more serious is Tactile and structural touch.

- Inserts fit all products- Classic fit is a pre-requisite to protection and presentation.

- Fix consistency- It should be part of the manufacturing system since the beginning.

By dispensing with these myths, the brands will be able to design packaging that will really be supportive of the long-term credibility.

Conclusion — Premium Packaging Is Engineered, Not Decorated

Finally, luxury jewelry packaging is a high-quality experience since it is designed as an entire system. The structure is rigid, the materials are high quality, the inserts are accurate, protecting and presentational, the finish is subtle in its implementation of sophistication and the manufacturing process is disciplined in bringing consistency in every production run.

Brands of jewelry that invest in this holistic thinking do not simply package their products, but provide a sophisticated customer experience that builds brand value in both physical store unboxing or online store unboxing. A combination of all components makes the packaging a continuation of the very jewelry: classy, trustworthy, and unquestionably high-end.