Introduction

The corrugated flute is very important in enhancing the chances of delivering a product with ease and it is not damaged. It is this seemingly simple shape of the wave that determines not only how robust your packaging is going to be but also determines how much money you will spend on shipping, what effect your packaging will have on the environment, and even how your brand will be perceived by the customer. You can be transporting delicate electronics, large machine products, or ready-to-sell products, but having information about corrugated flutes can transform your packaging strategy into more of a game of chance than accuracy.

You will find out the various kinds of corrugated flutes, the way each would influence the level of protection and cost, and learn how to choose the best flute in regards to your needs in this extensive guide. We are also going to discuss the most common pitfalls that result in ruined products or wasted finances, and provide some tips that can be practically useful to streamline your corrugated packaging plan.

What Are Corrugated Flutes

The core of corrugated cardboard is corrugated fluting. A corrugated flute is in essence, a wavy, ridged layer (also known as medium) between flat sheets of paper (also known as liners). The pattern of the waves forms a row of columns that are parallel to one another, and this pattern makes the unique structure that makes the corrugated cardboard known.

The structure is beautiful in its simplicity, and yet extremely useful: the outer covers furnish smooth surfaces to print and work upon, and the fluted medium produces air-pores, which serve several very important purposes. These air columns will be used as the natural insulators and keep contents out of the heat. They offer superior cushioning properties in shipping and handling because of the absorption of the impact energy. The vertical columns also entangle outstanding structural strengths, whereby light cardboard is capable of bearing a lot of weight at minimal material consumption.

This brilliant invention converts common paper into a shielding layer that insulates the products against compression, vibration, change in moisture, and physical effects to be allowed during the supply chain.

Why Corrugated Flutes Are Important

Corrugated flutes are not only important as regards to the protection but also in every other aspect of your performance in packing and your business.

The main advantage is structural strength and protection. The flute structure produces great compression strength, which enables the boxes to be stacked without any problem in warehouses and trucks. The shock-absorbing characteristics of the cushions absorb the impact and shock when dropped, and also the inflexible nature of the structure does not cause crushing of the contents. The size of the flute also offers different degrees of protection, with sensitive electronics needing a soft cushion, to heavy industrial components needing the highest compression protection.

Direct influence on your bottom line is the cost of shipping and the weight. The choice of flute influences box weight and dimensional weight calculations that are utilized by carriers. Thinner flutes save shipping, decrease the weight and size of the package, and thicker flutes can save money but provide better protection, resulting in fewer costly damage claims and returns.

Customer perception and marketability are affected by branding and appearance factors. The size of a flute influences printability – the smaller the flute, the finer the surface one has to produce high-quality graphics and detailed text. The unique texture of the flute types offers certain tactile experiences that have the ability to add excitement to the unboxing experience. Box integrity also defines the quality of boxes to retain their shape on the shelves in retail outlets, saving your brand name.

Green concerns have taken centre stage in the eco-friendly packaging policies. Corrugated flutes are made of the strongest material, and they use the least amount of material to provide effective protection with the least environmental impact. The fact that corrugated materials can be recycled contributes to the principles of a circular economy, and the opportunity to optimize the choice of flutes contributes to the minimization of the total amount of waste packaging.

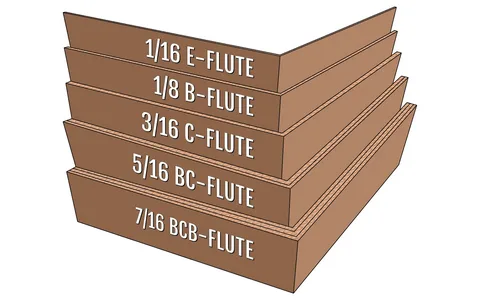

Types of Corrugated Flutes

The knowledge of the nature of various types of flutes will enable you to make knowledgeable choices when it comes to packaging. Every type of flute has its own benefits in application.

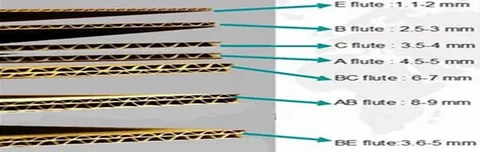

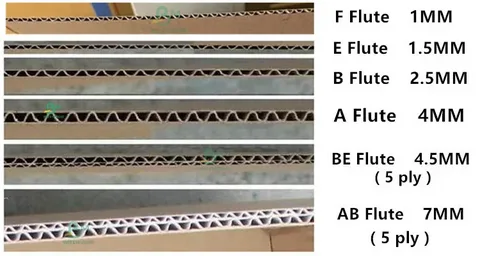

A-Flute is the original corrugated design with an estimated thickness of 5mm and 33-36 flutes/linear meter. This strong alternative gives it great compression strength and high cushioning qualities that ensure it is suitable for carrying delicate objects, glassware, and products that need maximum protection. But the thickness adds to the shipping fees and warehousing space, the rough surface would not allow finer printing details.

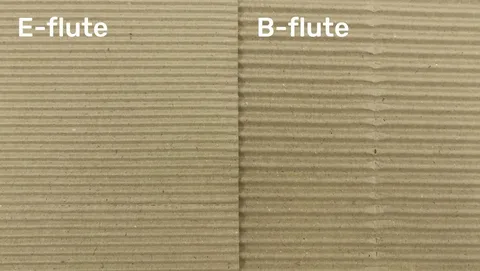

B-Flute is a middle ground of 3mm thick that has a flute pitch of 47-51 per linear meter. Being a versatile choice, it offers a good compression strength, and at the same time, exhibits a moderate shipping economy. The finer flute design allows the finer flute structure to print better than the A-flute, and therefore the finer flute structure is used in retail packaging when protection as well as appearance is important. B-flute can be used with small appliances, car parts, and in general shipping.

C-Flute is the most preferred with a thickness of approximately 4mm with 39-43 flutes per linear meter. This is a good, yet not outstanding, rug, which is very stackable and moderately cushioning, with high printability. C-flute is used in applications that require large volumes of shipping, e-commerce boxes, and general retail package types, where equal attention to all factors is needed.

E-Flute capabilities provide fine detail with a thickness of 1.6mm using 90-96 flutes per linear meter. This thin profile and a smooth surface allow high-quality printing and die-cutting accuracy, which makes it ideal in retail display packaging, point-of-sale materials, and products where shelf appearance is essential. E-flute offers sufficient security on lightweight products, as well as low shipping charges.

F-Flute is the best alternative with only 0.8mm thickness but with 125-131 flutes per linear meter. This very thin option provides superior printability to solid cardboard with the corrugated advantages of structure. F-flute is also used in luxury packaging, cosmetic boxes, and other areas where the appearance of the pack with a high value and low thickness is the most important.

The type of flute selected should depend on your needs. Use A-flute to offer maximum security to delicate or precious goods. Select B-flute when performance is needed that is moderate in protection. ANCE-flute with large volumes of shipping and general packaging. Pick E-flute in cases where appearance on the shelf and printability are important. F-flute should be used when the appearance is important and the thickness is required to be low.

Other Key Factors in Corrugated Packaging

Flute type is only one of the ingredients of the corrugated packaging performance equation. There are other factors that make a great contribution to the outcome.

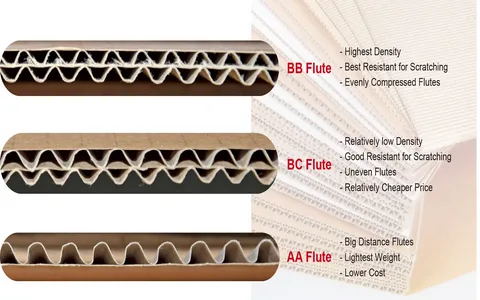

Construction types of boards increase the resistance and protection properties of single flute layers. Single-wall construction incorporates one flute of insulation between two liners, which has rudimentary protection at minimal expense and weight. Two layers of flutes with three liners make this construction type a double-wall construction, which gives the compression a huge boost of strength, as well as cushioning to the heavier or more delicate objects. Triple-wall construction provides the best protection of three layers of flutes and four liners that fit heavy industrial products or very sensitive products. Single-face construction involves the utilization of a single liner, which is attached to fluting, which is mostly used to wrap and fill voids.

Box style variations are used to accommodate various packaging needs and shipping conditions. General shipping takes the most economical and commonly used design in regular slotted containers (RSC). Full overlap designs enhance the bottom strength of heavier products. Half-slotted containers are effective in open-top loading. Telescoping boxes are useful when the size of the product varies because the height can be adjusted, and specialty designs, such as die-cut boxes, provide an opportunity to create an unusual shape for the retail presentation.

Functional packaging becomes an effective selling tool with printing and finishing options. Flexographic printing is a cost-effective multi-color graphics that can be used for large runs. Variable data and short run with fast turnaround are facilitated by digital printing. Lithographic printing offers the best graphics to be used in high-quality packaging. Surface finishes such as UV coating, lamination, or embossing enhance durability and tactile effects. Die cutting is done to make product-specific shapes and openings in the windows.

How to Choose the Right Flute for Your Needs

To choose the best type of flute, it is necessary to analyze the specifications of your needs and priorities. A systematic method is what will provide optimum protection at to cost of functionality.

Product characteristics. The basis of flute selection is product characteristics. Glass or electronics are fragile and require the thickest flute (A or C) to have the highest level of cushioning and impact protection. There must be a high compression resistance needed in heavy products that necessitate C-flute or double-wall construction. Thinner flutes (E or F) can be used in lightweight items to reduce shipping costs. The shape and size of products determine the box design and flute direction in order to have maximum strength distribution.

Balancing protection, cost, and shipping weight. The pricing of the protection, cost, and shipping weight needs to be balanced by being aware of the trade-offs among various factors. A heavier flute is also more protective, although the material is more expensive, and shipping becomes more expensive. A slim flute is cheaper, although it may need more internal wrapping to ensure proper protection. The total cost of materials, shipping, and possible damage claims should be calculated to determine which solution is the most cost-efficient.

Environmental and logistical considerations: These are environmental and logistical factors that influence the performance of flutes during the supply chain. The high shipping distance and numerous handling operations are in favor of stronger types of flutes. The climate changes caused during transportation might need more moisture or temperature shielding. The compression strength requirements are affected by the storage conditions, especially in warehouses where there is high stacking. Imagine the whole process of manufacturing, all the way to end-users, to pinpoint the key protection requirements.

Common Mistakes and Myths

It is possible to considerably increase the packaging performance and minimize costs and wastes through the avoidance of common misconceptions and mistakes.

Over-packaging and under-packaging. Excessive and minimal packaging lead to issues and unnecessary costs. Over-packaging causes unnecessary waste of materials and high shipping expenses with no commensurate protection advantages. Under-packaging expenses result in the claim of damage, consumer dissatisfaction, and replacement costs, which are usually more than the benefits of the savings made due to the decreased packaging. It is in the ability to align the protection levels with the real risk factors or risk factors as opposed to having more or less risk that is always better.

Focusing solely on flute thickness when the thickness of the flute is considered with no regard to other important factors, the outcomes are suboptimal. Weight and quality of the liner are also important for strength and puncture resistance. The type of protection has a greater effect on board construction (single-wall vs. double-wall) rather than on flute type. Many applications consider edge crush strength, burst strength, and other specifications more important than thickness.

Persistent myths. Myths have remained in use to affect the packaging decisions even in the face of opposition. The thinking that thinner flutes are always cheaper is not sensitive to the fact that fine flutes frequently need more advanced production and better materials. The belief that the thicker is the better protection does not take into consideration the cases when it is the cushioning properties that are important as compared to the compression strength. Knowing such subtleties will help avoid expensive errors in choosing the flute.

Case Studies and Examples

Practical uses of flute selection show how the correct choice of the flute can put the theory into practice and the tangible benefits.

Case study on Electronics manufacturer: A smartphone accessories company initially applied A-flute packaging to all its products, which made shipping expensive and oversized packages. Following the analysis, they changed to E-flute to ship lightweight products such as cables and screen protectors, which saved them 23 percent and still provided sufficient protection. On heavier products such as power banks, they switched to C-flute, which enhances stacking in warehouses and minimizes the rate of damage to 0.8 instead of 3.2%.

Cosmetics brand transformation: A high-end skincare company that was shipping in generic C-flute shipping boxes was getting complaints of a bad unboxing experience and bad secondary packaging. The experience of customers was altered as F-flute was changed with high-quality lithographic printing, which also decreased the package size by 30 percent. The premium flute selection investment had a 15 percent rise in packaging that boosted customer satisfaction rating and decreased the turnover rate.

Optimization of industrial parts: A machinery parts distributor saved 40 percent of packaging expenses due to the choice of flutes. Heavy steel parts that were using triple C-flute with triple-wall were changed to double-wall C-flute with reinforced corners and still retained the protection, but had lesser weight. Hand-sized precision components were taken out of C-flute and into B-flute, which is more economical in shipping, without affecting the delicate surface protection.

Tips for Optimizing Corrugated Packaging

The application of strategic optimization solutions will help optimize the benefits of the correct choice of the flute as much as possible: reducing the cost and environmental footprint.

The approaches to saving costs are aimed at efficiency enhancement during the packaging. Right-sizing packages will do away with unused area and charges on dimensional weight. The uniformity of the boxes within the different lines of products also facilitates bulk buying price discounts and easier management of the inventory. Packaging has been designed to nest efficiently when storing to reduce the size of the warehouse space. Collaborations with manufacturers to optimize die-cutting patterns cut back on waste material and establishment expenses.

Sustainability factors can improve environmental objectives, but in many cases can give some economic benefit. Naming recycled contents in liners and fluting lowers the environmental impact and, in some cases, cost. Plastic making eco-friendly packaging by making it easy to disassemble and reuse will enhance end-of-life results. Another method to minimize the material use is the selection of flutes to minimize the ecological footprint. Adoption of programs of take-back on returnable packaging produces closed-loop programs.

Close co-operation with manufacturers will guarantee the best outcomes of flute selection and the design of packaging. Inquire with manufacturers of testing capacity to confirm the levels of protection before making massive orders. Negotiate on volume order and order at the best price and priority. Ask for different types of samples of flutes to compare the actual performance of your products. Collaborate with design teams to optimize graphics and structural features of your preferred type of flute.

Conclusion

The corrugated flutes are the engineering basis that takes plain paper through advanced systems of protective packaging. The knowledge of A, B, C, E, and F flute features would enable you to apply the necessary protection levels to products based on product requirements and minimize costs and environmental impact. Successful flute selection depends on the analysis of the needs of the specific products, such as product fragility and weight, to shipping distances and branding needs, rather than on the one-size-fits-all methods. Through the avoidance of the most common errors, such as over-packaging or concentrating on the thickness area, by taking into consideration aspects such as building the boards and printing, you can develop the packaging solutions that not only offer protection to the product, but also customer satisfaction and business goals. With the fine electronics or the mighty industry parts, the appropriate flute selection is the initial stage of packaging triumph that adds worth along the entire supply chain.