Introduction

And did you hear that the world market of packaging cartons will be one hundred and seventy billion dollars by 2030, and the driving force will be the rapid increase in e-commerce and the rising environmental awareness? With consumers being more conscious of sustainability-related problems and brands focusing on packaging which can be protective, attractive, and responsible to the environment, carton packaging became one of the leaders in the packaging industry.

This is an all-encompassing guide about carton packaging, covering all necessary facts about the basics of the packaging including materials and groundbreaking innovations that define the future of the packaging. As a brand manager who wants to get an ideal packaging solution, as an entrepreneur who is opening up a new product or just as an individual who wonders what is the packaging that encloses our lives, you will find out the reason as to why carton packaging is important to the brands, the environment and the consumers themselves.

We shall trace the history of carton packaging, discuss several types and uses of this packaging, review its design factors, discuss the effects on sustainability, and showcase the upcoming trends that are transforming the industry.

What is Carton Packaging?

Carton packaging is a type of packaging whereby the material is mainly a paperboard – a paper based material, which is thicker and more rigid than ordinary paper, but light as compared to corrugated cardboard. These multi purpose packages can be used as safety boxes and as potent sales tools, including not only cereal and cosmetics, but also electronics and luxuries.

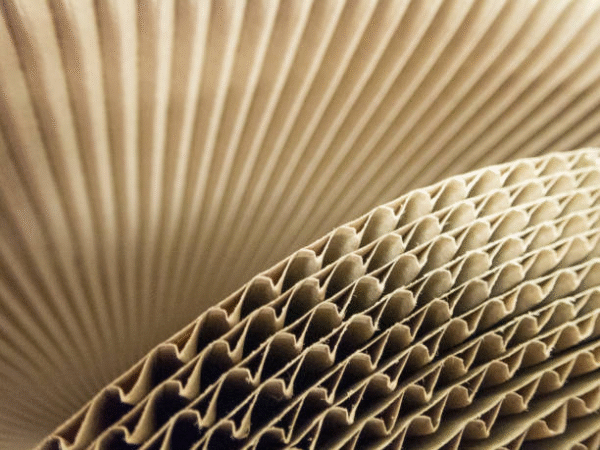

The carton term has a number of different categories. The most used called folding cartons are constructed of a single sheet of paperboard which is printed, die-cut and folded into shape. These are lightweight but strong containers that in general measure between 0.014 and 0.024 inches thick. Rigid cartons, by contrast, are made of several layers of paperboard and chipboard forming more robust containers of often very high quality items such as jewelry boxes or high-quality electronics.

The major components in carton packaging are paperboard substrate, protection and printability covering, assembly adhesives and finishing foils, varnishes or laminates. The paperboard itself is usually composed of virgin wood fibers, recycled material or a mixture of both wood and recycled material, depending on the purpose of application and whether it has to be sustainable or not.

Carton packaging is different as compared to other types of packaging. Cartons are not constructed of corrugated middle layer sheets as opposed to corrugated boxes that have a fluted middle layer which provides extra strength to them. This makes them lighter and more fit to be displayed in the retail shelves but less sturdy to be used in shipping. Cartons are better to print and is more environmentally friendly than plastic as the latter can protect against moisture and gases better. Glass and metal containers are better in terms of protection of the product but not in terms of design flexibility and cost effectiveness compared to cartons.

The Evolution / History of Carton Packaging

The carton packaging story traces back to the year 1817 when Sir Malcolm Thornhill made the first commercial cardboard box in England. The folding carton as we recognize it today, however, came into being in 1879 when Robert Gair accidentally invented the process when a metal rule that was used to crease bags instead slipped and cut through the material creating the first die-cut and folded carton.

The early 20th century was characterized by the innovations in carton packaging. The first machine made cartons were created in the year 1908 and they led to large consumer production in addition to great cost reduction. The introduction of wax-coated cartons to use in packaging liquids in the 1930s transformed the dairy industry with the well-known milk carton. World War II was a boost to innovation because the companies were in need of alternatives to the metal packaging because of shortages during the war.

In the 1950s and 1960s, significant changes occurred in the printing technology, such as multi-color offset printing that turned cartons into a potent branding tool. With the introduction of polyethylene coating in the 1960s, superior moisture protection was possible and cartons were introduced to frozen products and other sensitive items.

The last several decades were devoted to the struggle towards sustainability. Increased use of recycled content and water-based inks was used in the 1990s. The 2000s came with biodegradable coating and plant materials. Improved packaging features such as QR codes to track products, temperature-sensitive inks and improved barrier coating which extend shelf life but are recyclable are innovations of today.

Benefits of Carton Packaging

Carton packages are more than excellent in giving protection and functionality and are cost-effective at the same time. The nature of paperboard is strong enough to offer sufficient protection to the majority of consumer goods throughout transportation and storage and at the same time, due to its lightness, shipping costs and environmental impact are minimized. The stiff design ensures integrity of the product, helps to avoid crushing and to stack the products efficiently in warehouses and in retail outlets.

Carton packaging in terms of branding cannot be compared with others. The wide and smooth surfaces offer the necessary space of graphics, product information, and brand messages. The vibrant colors, complex designs and special effects made possible by high quality printing enable the consumer attention and passing of the brand values. The capability of developing distinct structural designs is another way of distinguishing products within congested retail shelves.

Carton packaging is becoming an appealing feature to eco-friendly brands and consumers due to its environmental benefits. Cartons are made mainly out of renewable wood fibers and therefore have a much lower carbon footprint than plastic ones. Majority of cartons can be recycled with the help of available municipal programs and most of them contain recycled materials. Paperboard is biodegradable, and thus even mismanaged cartons will degrade in nature as opposed to the unbiodegradable plastic packaging.

The possibility of unlimited customization is made possible by design flexibility. There are endless shapes, sizes and forms in which cartons can be produced to suit certain product needs and brand image. Complex structural features such as windows, handles and dispensing mechanisms are possible because of advanced methods of die-cutting. Surface finishing such as embossing, foil stamping, and specialty finishing are provided to provide the touch and look.

Carton packaging is more preferred in terms of cost. The raw materials tend to be cheaper than the plastic substitutes and the lightness of the material helps to cut down transportation costs. Good manufacturing procedures allow competitive prices, particularly when the amounts are large. The storage costs are reduced because of the option of sending the cartons in the form of a flat and then assembling when required.

Types / Styles of Carton Packaging

Tuck Top Boxes have flaps that fold inside the top of the box without the use of any type of adhesive or tape. These are general purpose boxes that can be used in retail packaging because the ability to open and reclose is essential. Advantages are affordability, rapid assembly, and convenience to the consumers. They however might not offer safe closure of heavy products, and can open accidentally during handling.

Reverse Tuck Boxes have the top flaps and bottom flaps opening in opposite directions and is thus a better closure than a typical tuck box. They are normally applied in pharmaceuticals, cosmetics and food products. The design eliminates chances of unintended opening and gives the piece better tamper evidence but assembly would need more finesse and could also be a little more costly to manufacture.

Sleeve Boxes are made up of two sections which include the outer sleeve and an inner tray which slides in and out. The type of premium packaging is used on luxury goods, electronic products, and gift items. It is worth the premium costs due to the sophisticated appearance and perceived price, yet the two-piece design adds to material consumption and construction complexity.

Tray and Lid Boxes have a distinct lid which is place over a bottom tray, with either a small overlap to ensure it closes well. These boxes are good product visibility when opened, and are commonly used to serve food, in retail showcases as well as high quality products. Although they will provide better access to contents, they will need more material and shipping space as compared to single-piece products.

Pillow Boxes are rounded in shape forming a pillow shape that makes them suitable with small gifts, jewels and promotional materials. Its distinctive shape is highly shelfable, and can be produced out of a single die-cut blank. There is however a curved structure which restricts printing space and could not be convenient in stackable storage.

Rigid Boxes are made out of heavy chipboard and are lined with printed paper or any other ornamental materials. These are high endurance and luxurious premium boxes that are offered at high end products such as jewelry, electronics and cosmetics. These advantages are given at a higher price and weight.

Materials and Finishes

Quality carton packaging is based on paperboard selection. Virgin paperboard is produced using fresh wood fibers and is stronger, can be printed and is also safer to use with food that needs top-performing characteristics. Post-consumer paperboard in recycled form with different proportions of post-consumer material offers environmental benefits and cost reductions with performance requirements in most applications.

Kraft paperboard is a natural brown color and of high strength type, which makes it ideal to use in the products that are positioned as natural or eco-friendly. Coated paper board boards have clay coats and are more printable, resistant to moisture and allow smooth graphics to be applied to it. Plastic films or foils layers are added to the laminated cartons to provide higher barrier properties, but this can affect recyclability.

Basic paperboard is then turned into strong brand experiences with printing and finishing options. The high quality and uniformity of the colors produced in large production runs is achieved in offset printing, whereas short production runs and variable data applications are possible in digital printing. Flexographic printing provides solutions that are cost effective when dealing with simpler designs and it has been applied to food packaging especially because of using water based inks.

Methods of finishing are both tactile and aesthetic and offer functional advantages. Embossing is used to produce raised features that provide a sense of texture and high-end feel whereas debossing is used to form recessed features to provide subtle elegance. Foil stamping uses metallic or pigmented foils in a luxurious and branding aspect. UV coating includes protection of high-gloss and creates color vibrancy, whereas matte coating is sophisticated and provides sense.

The safety and compliance are the most important factors, particularly food contact applications. The approved inks and coating by FDA are safe to consumers, and barrier coating prevents moisture, oxygen and grease destruction. The adherence to the regulations in Europe as in the case of REACH and other food safety standards necessitate close attention to materials selection and testing.

Design & Branding Tips

Development of outstanding carton packaging needs a strict balance of image and practicality. The psychology of color is vital in consumer perception. Warm colors such as red and orange evoke the perception of energy and excitement and cool colors such as blue and green indicate trust and sustainability. The contrasting color pairings provide the visibility of the shelves, whereas the matching colors are used as a pair in order to provide the harmony and sophistication.

The choice of typography has a strong influence on the brand perception and readability. Sans-serif fonts with bold letters convey the idea of power and modernity, whereas script fonts are associated with the concepts of elegance and tradition. Font sizes and weights are used to create a hierarchical flow of consumer attention to the main points of information such as the names of the products, benefits, and instructions on how to use them. The legibility of the text should be ensured in all the text elements, in regards to the distance of viewing and the illumination of retail scenarios.

The imagery strategy must be in line with brand positioning and target audience. Lifestyle photography relates products with aspirations of the consumer whereas product photography presents features and advantages. Examples provide elasticity and the ability to distinguish brands in saturated categories. Patterns, textures and icons provide a visual appeal and aid in brand recognition.

Aesthetics and functionality must be balanced putting into consideration the structural requirements and consumer behavior. Ease of opening such as perforation patterns and tear strips do not compromise package integrity and are easy to use. The window cutouts will give a view of the product but will have to be located in a way that does not make it structurally weak. Mechanisms of closure must be user-friendly and safe to the overall concept of design.

Branding that is environmentally friendly is becoming a major aspect of design choices with consumers opting to seek sustainability. The information on recyclability, renewable materials and decreasing the environmental impact should be displayed on the message. Minimalist artworks that consume less ink and use none of the elements that do not add value show a dedication to the idea of conserving resources. Packaging instructions enable consumers to properly dispose of packaging.

Cost Factors & Manufacturing Process

The knowledge of cost drivers will assist in making a wise decision regarding the carton packaging investment. Material expenses are usually 40-60 percent of the overall packaging expenses, and paperboard grade, thickness and finishes have a strong influence on the price. High-quality materials and high-value substrates are priced more highly, but can be worth the expense in terms of improved brand awareness and performance.

Manufacturing cost is directly proportional to size and structural complexity due to die-cutting needs, folding operations and material efficiency. Complex parts with complex incisions demand special tools and could lead to higher wastage in the manufacturing process. Quantity issues are based on the common economies of scale – the larger the order the lower the unit costs as the material is more efficiently used and the production runs are longer.

Specialty processes like foil stamping and embossing are highly cost-effective and demand more equipment and time to complete. Multi-color printing is also costly when compared to single color applications, but modern printing technology has decreased such premiums. Enhanced performance or appearance coating and treatments increase the material and processing costs.

Design development and structural engineering form the starting point of the manufacturing process to make sure that it is workable and manufacturable. Prototyping enables form, fit and functional testing prior to the production tooling being committed to. Die-cutting tools are produced in line with exact requirements to cut and crease.

The process of production is usually followed by the sequence printing, die-cutting, folder-gluing and quality- inspection. Moderate manufacturing plants have advanced technology of accurate registration, consistent folding, and gluing processes. There are quality control methods which involve dimensional checks, print quality test and functional testing to maintain performance levels.

Environmental Impact & Sustainability

Carton packaging performs better than many other alternatives in several metrics in terms of environmental performance. Life cycle studies reveal that carton has always recorded lower carbon footprint than plastic containers mainly because the wood fibers are renewable and the manufacturing process is efficient. The fact that it can source materials in sustainably managed forests also minimizes environmental impacts.

One of the key benefits of using carton packaging is recyclability, where paperboard-based containers are accepted by the majority of municipal recycling initiatives. Recycling makes the process of separating and reprocessing fibers into new products efficient to create a circle economy of packaging material. In most developed markets, carton recycling is more than 70 percent currently, much higher than recycling of plastic packaging options.

Biodegradability offers a benefit in carton end-of-life to those that accidentally end up in the natural environments. In comparison to uncompromising plastic products, paperboard is biodegradable and it usually requires several months, but not decades or centuries, to decompose. This feature decreases the accumulation and impact of the ecosystem on the environment in the long term.

Different certifications and standards are used to determine sustainable carton packaging. Forest Stewardship Council (FSC) certification is a guaranty of responsible management of forest activities, and Programme for the Endorsement of Forest Certification (PEFC) is an alternative certification. Sustainable Forestry Initiative (SFI) certification is concerned with the practices of forests and North American chains of custody.

Sustainability efforts in carton packaging are becoming the responsibility of brands and consumer requirements. Business firms are employing holistic approaches towards sustainability which include sourcing of materials, manufacturing effectiveness and disposal practices. Sustainable packaging materials are preferred by the consumers, and most of them are ready to pay high prices on the environmentally friendly products.

Choosing the Right Carton Packaging for Your Product

The process of choosing the best carton packaging must be done through logical consideration of product needs, brand goals and feasible limitations. Packaging decisions are primarily based on the properties of the product – delicate products require either the structural design or padding inserts to provide them with better protection, and liquid products need barrier finishes or other special sealing devices. The consideration of weight impacts the choice of materials used as well as the design of the structure in order to have sufficient strength without being overweight.

Budget limitations dictate all the ways of packaging such as the material used, printing or quantity, and finishing. Setting realistic budget parameters at the early stages of the design process allows to have realistic trade-offs between cost and performance. The value engineering techniques might find the possibilities of cutting down the expenses without interfering with the necessary operations or brand influence.

Aesthetic decisions should be made on the basis of brand image but they should also be in line with the general brand strategy. Luxury brands will normally invest in high quality material and advanced finishing methods to support quality perceptions. Value brands can focus on practical advantages and affordability, but still have a professional aspect of appearance.

The use of environmentally friendly commitments is also becoming a driving force in the choice of packaging as companies have set sustainability targets and consumers have shown preference towards environmentally friendly packaging. The brands have to strike a balance between the environmental goals and the performance needs and cost. Products can become differentiated using clear sustainability messages and attract the attention of environmentally aware consumers.

Matched product category facilitates the determination of suitable packaging styles and material according to industry requirements and expectations of their consumers. Food products tend to need barrier performance and regulatory support whereas cosmetics are focused on visual performance and luxury positioning. Electronics packaging should be able to offer sufficient protection and at the same time allow retail display and consumer analysis.

The evaluation of the suppliers must include technical, quality systems and service levels as well as the pricing. Demand elaborated capability statement, facility certification and customer reference. A variety of design and finishing options should be added to sample requests to test the quality standards and consistency in production.

Emerging Trends in Carton Packaging

The use of smart packaging is turning the conventional carton into an interactive brand experience and functional device. QR codes allow immediate access to product details, use guidelines and brand content and valuable consumer behavior data. NFC chips provide touchless interfaces of high-end products and reward schemes.

Traceability systems are gaining significance in food safety, verification of authenticity and visibility of supply chain. The integration of blockchain allows the ability to track the origin of raw materials to the consumer purchase point, having never been able to achieve the same before. The systems not only help in regulatory compliance but also help consumers build confidence in the products in an era where awareness of the origin of products is on the rise.

The technology of digital printing is transforming short-run customization and variable data applications. The on-demand production capabilities allow changing seasonally, regionalization, and customized messaging without the usual minimum quantity requirement. This is flexible enough to support test marketing, limited edition and mass customization strategies that could not have been achievable in the traditional printing techniques.

Sustainable material innovations are moving on to develop the carton packaging performance and lower environmental impact. Barrier coating, which is made of plants, eliminates petroleum-based products and can still resist moisture and grease. The inks made of algae are renewable alternatives to the usual printing materials. Nano-cellulose reinforcement improves strength properties without the use of synthetic materials.

Packaging innovations are being influenced by consumer behavior shifts in the convenience, portion control, and disposal practices. Multi-use applications and the reduction of food waste is met with features that are resealable. Portions that are single-serving react to the changes in lifestyles and health awareness. Easy-open designs cater to the aging population and access needs.

The evolution of regulations still influences the requirements of packaging by the extended producer responsibility legislation, the restrictions of single-use plastics, and the strengthened mandates of recycling. Regulatory changes are something companies should expect and therefore they should be able to make changes to their packaging strategies in advance to prevent either compliance problems or market access problems.

Case Studies / Examples

Apple has also brought about the revolution of the electronic packaging by designing a minimalistic carton design that is a reminder of their brand philosophy of elegant simplicity. Their iPhone packaging relies on the rigid construction and exact die-cuts to provide the unpacking experience that is packaged in a high-end positioning. Their compact size reduces the usage of materials and still offers a sufficient level of protection and the color scheme is largely white, which helps to promote the consistency of the brand in their product range.

Patagonia The carton packaging materials used at Patagonia are quite genuine and persistent in their environmental commitment, as they are made of pure materials of 100 percent recycling, and the inks they use are soy based, even though the packaging remains very catchy in their visual presentation. They have packaging that directly conveys the sustainability message without undermining the brand strength or the protection of the product. Clear reporting on packaging environmental impact by the company will establish confidence and loyalty among the consumers.

Tiffany & Co. have capitalised on their USP blue boxes being part of their brand and being strongly visible elements that add emotional association and value. It has made the unique color to be associated with quality and luxury, which illustrates how the carton packaging can exceed the functionality demands to be strong brand assets. The hard-built and high-end finishing adds to quality impressions and warrants high costs.

These are the examples of the successful approaches to the balancing between the functional demands and the brand requirements and the consideration of consumer preferences and the market needs. Both companies have designed packaging solutions which help them in supporting their value propositions and positioning in the market.

Conclusion

Carton packaging is much more than a mere container, it is an advanced marketing, environmental and practical need that is constantly adapting to new demands of the consumer and technological potentials. Since its simple origins as plain paperboard boxes up to the present intelligent, green, and aesthetically beautiful packages, carton packaging has displayed its functionality and usefulness in innumerable ways and in numerous industries. The combination of sustainability needs, technological advances, and consumer expectations is resulting in further development of materials, manufacturing technologies, and design possibilities. The strategic significance of considering careful carton packaging choices in consumer relationships will continue to increase as the brands become increasingly conscious of packaging as an important consumer touchpoint. You are either introducing a new product to the market, assessing the effectiveness of your existing packaging strategy or you are considering how your business can integrate with the sustainability strategies and now is the time to consider how modern carton packaging solutions can be used to service your business goals and consumer needs in terms of quality, convenience and environmental friendliness.