Introduction: Why the Material of Cereal Boxes Matters

It is estimated that 2.7 billion boxes of cereals are sold in the United States alone every year with millions more being manufactured throughout the world. That is about 150,000 tons of packaging material trolling the cereal industry every year – and that would end up in recycling bins or landfills. However, regardless of their ubiquity, not many consumers know how these common containers that hold their morning nutrition are made.

The choice of the material, with which cereal boxes are made, is not only a matter of cost but a complicated process that influences the efficiency of the manufacturing process, the perception of the brand, environmental impact, and the experience of the consumer. A weak box that rips when transporting the product may ruin brand loyalty and high-quality materials may increase the perception of a product. Likewise, shoppers with an eco-like mind are placing more and more emphasis on the sustainability of packaging, so the choice of materials is an important marketing factor.

Here, in this complete guide, you will find out which materials are utilized in making the boxes of different cereals, including the conventional chipboard, and new sustainable options. We will investigate the impacts of material options on design opportunities, pricing, and environmental footprint and also make some practical suggestions to brands interested in streamlining their packaging approach.

What Are Traditional Cereal Boxes Made Of?

The majority of the traditional cereal boxes are made of chipboard which is also referred to as the grayboard or recycled paperboard. This substance is a composite of several layers of recycled paper fibers that have been pressed together to form a strong but lightboard. Although technically, it is not cardboard, as the consumers consider it to be, chipboard is a different product to corrugated cardboard, which is corrugated with a fluted inner layer to enhance strength.

The packaging of the cereals is controlled by chipboard due to strong economic reasons. It is cheap and is therefore suitable in large volume production and the surface is smooth enough to be printed to some basic graphics and text. It is comparatively simple to die-cut and fold the material thus simplifying the process of manufacturing the material and maintaining reasonable labor costs.

There are however significant restrictions associated with chipboard. In some cases, it may need more layers of coating which is costly since its color is grayish and can be visible with the help of lighter inks. The low strength of the material allows boxes to crush or dent easily when shipped and handled. Also, although chipboard is made with recycled materials, the process can be undermined by some printing inks and finishes, posing a green challenge to the brands and consumers who focus on sustainability.

Top Alternative Material Options

Standard Cardboard

Corrugated cardboard as compared to chipboard has huge strengths especially in printability and strength. Its corrugated design offers the best crushing resistance and stacking capacity, so it is suitable to those goods that need additional security during distribution. The quality cardboard keeps its surface cleaner and whiter, which means that it can be printed more vibrantly, and the colors can be reproduced more accurately, which promotes more vivid visual designs designed by the brands.

When the shelf life and the safety of the product warrant the comparatively low cost of standard cardboard, premium cereal brands and specialty products frequently opt to use it. This material is commonly used in organic cereals, imported goods, and limited editions in order to express quality and detail. Its better durability also prevents loss of products because of damaged packaging which can cover some of the extra cost of material.

The main disadvantage of standard cardboard is the price – it is generally 15-30 percent higher than chipboard. This can have major repercussions on profit margins and competitiveness in retail pricing when it comes to the mass-market cereals, which are mostly looking at price as their major competitive advantage tool.

Kraft Paper / Kraft Board

Kraft paper and kraft board have become popular with brands that focus on natural or organic positioning or artisanal positioning. This material is made of the wood pulp by the kraft process and is highly biodegradable and has a unique natural brown color that conveys friendliness to the environment and natural ideals. The textured surface is slightly textured to enhance a high-quality feel that can attract customers who are looking at high quality wholesome products.

Kraft materials are the best in environmental perspective. They are usually made of some wood fibers that are sustainably acquired and can be completely decomposed in the composting facilities. A variety of kraft papers are certified by Forest Stewardship Council (FSC), which is third-party validation of responsible sourcing behavior.

Nonetheless, kraft materials are difficult to print. The natural brown color does not allow much degree of design and to get bright colors will require specialized inks or extra coating processes. Text and finer details might not be reproduced as sharp as on white surfaces. These constraints make kraft board best appropriate with those brands where the earthiness of minimalism aesthetic technique is applicable, as opposed to those that need bright and intricate graphics.

Other Emerging/Specialty Materials

Innovations in the packaging industry include continued use of paperboard that has the newest recycled material with higher percentages of post-consumer recycled material. These materials are also good and less harmful to environment but they might need to be specifically chosen in terms of compatibility of inks and coating used so that they can be recycled.

Barrier treatment is added to coated paperboards in order to be moisture resistant and protect shelf life. The materials are especially useful in cereals that have oils or nuts that may turn rancid when exposed to moisture. Food-safe coated surfaces ensure the preservation of the product, as well as printability.

The alternative that is completely compostable and biodegradable is the future of sustainable packaging. These materials may include agricultural waste fibers or natural materials which have been treated specifically, and they can be broken down completely in industrial composting facilities. They are not as cost-effective and flexible in their design, but they are highly desirable to the consumer segment of the population who cares about the environment and can afford to pay higher prices on sustainable goods.

Design Elements That Make a Cereal Box Stand Out

Cereal box design is based on learning your target demographic. Children are sensitive to bright colors, cartoon characters, and interactive features such as games or prizes whereas health conscious adults are sensitive to clean and information based designs that focus on nutritional benefits. Premium quality and artisanal is needed in ceramics; luxury or artisanal cereals demand complex aesthetics and imply high quality and artistry.

The elements of brand identity should be used in a coordinating manner with the material choice. The logo should have as much exposure as possible and its typography must be legible on various surfaces of the materials and colors used. Images that have high quality are best reproduced using high quality materials, whereas simpler graphics can be reproduced using natural kraft surfaces.

The psychology of colors is important in consumer perception and purchase behavior. Warm colors such as orange and yellow imply energy and vitality and are therefore popular with breakfast products. The color green is a representation of health and naturalness, and the deep blues and purples may mean luxury or specialty positioning. The color and texture of the materials used to adjust the color of the printed ones and the designer has to adjust their palettes.

Minor details can have a substantial value addition and shelf presence. Embossed text or logo develops touch appeal and high-quality feel. Gloss and matte finishes have the ability to emphasize or provide contrast of certain design features. Die-cut windows enable the consumers to observe the real product which creates trust and appetites. These improvements, however, would add more expenses and can affect material recyclability.

Box Styles & Structural Considerations

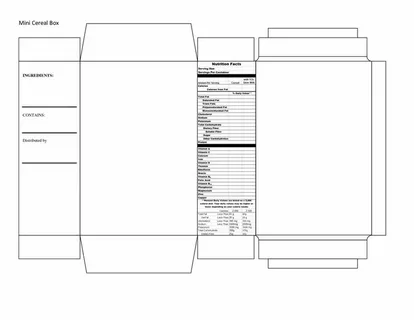

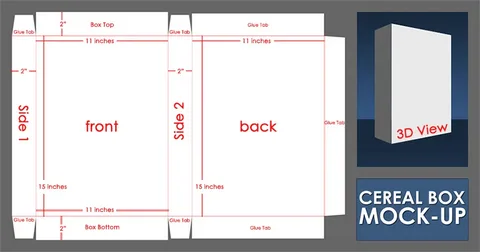

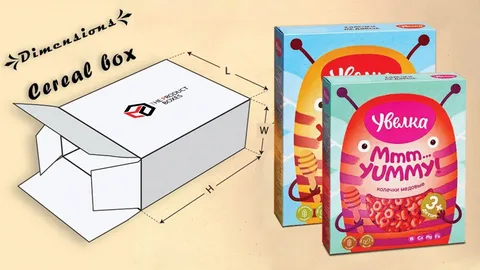

The most common example of the rectangular “brick” is used in packaging of cereals in its usual form as it is efficient in manufacturing, shipping and display in the shelf. This common book format achieves the maximum product volume at the least use of materials and shipping space. Others have shown different proportions – tall and narrow in high positioning or short and wide in family-size products.

Other structural strategies are functional or marketing in nature. The borrowed milk carton technology has gable-top designs that provide a distinctive shelf presence and pour functionality. Cylindrical containers are highly protective to fragile cereals and are more difficult to produce, and might not be shipping efficient.

Shaped panels and die-cut windows may give shelves a unique look at the cost of added complexity and expense to production. These characteristics are effective when using high quality materials capable of sustaining structural integrity even at low surface area.

The issue of functionality goes beyond the aesthetic to the practical functionality. The inner bag should be effectively shielded against any puncture, wetness and pests. Most designs also have moisture resistant designs or special coatings to increase shelf life. The ease of opening and reclosability would make consumers more comfortable, and the structural integrity should support retail operation and domestic use.

Display requirements and shipping issues play a key role in structural decision making. During transportation, the boxes should be stacked safely on top of each other and they should remain in the shape at the weight of several units. Some considerations undertaken in retail display relate to appearance of boxes when they are in stock and how the design will look like when partially covered by other products.

Sustainability: How to Make Your Cereal Box Eco-Friendly

The choice of recyclable materials is the basis of green cereal packaging. Post-consumer recycled paperboard conserves the virgin materials demand and has sufficient performance in most of the applications. The recycling process, however, needs a keen eye to the compatibility of the inks and coating in order to make sure that the materials could be effectively subjected to the recycling process.

Another possible end-of-life solution is compostable materials, which can be of interest to environmentally conscious consumers. These materials are also decomposed in the industrial composting systems, but such facilities are not available everywhere. Home-compostable alternatives are available but they can be limited in performance that influences the product protection.

Surface treatments and printing inks have a major effect on the environment. The use of soy and water inks minimizes the effects of chemicals as opposed to the use of petroleum inks. UV-curable inks do not cause volatile organic compounds but can compromise recyclability. Aqueous finishes offer greater environmental profiles than plastic-based finishes because they are moisture resistant.

The tendency to remove plastic inner bags has its opportunities and challenges. Inner bags made of paper have better chances of being recycled, and might not be as protective against moisture. Biodegradable plastic alternatives are preserving protective properties, and less harmful to the environment in the long run, but usually are more expensive than regular plastics.

Environmental claims that are credible are with the help of third-party certifications. Forest Stewardship Council (FSC) certification guarantees responsible management of forests, whereas Cradle to Cradle certification considers the whole cycle of products. The certifications assist the brands to convey their environmental responsibility and address growing complex consumer demands.

Cost vs Benefit: Budgeting for Quality and Ethics

The choice of materials has a direct relationship with the costs of production and the expensive choice usually increases the cost of packaging by 20-50 percent. Nonetheless, this price increment has to be considered in comparison with possible advantages such as improved brand image, minimized product wasting, and attracting the attention of environmentally-conscious customers ready to spend high prices.

The complexity and the material requirement are proportional to printing and finishing costs. Basic designs on basic materials save on costs whereas, different colors, special finishes and elaborate structural designs are costly. Brands have to strike a balance between visual appeal and financial limits and the demands of the target market.

The overall cost formula consists of others in addition to initial material costs and printing costs. High quality packaging can minimize product damage and returns which are subsidized by the increased cost of packaging. Shelf appearance can be improved, selling velocity and market share can be boosted, extra revenue will be received, and it is worth investing in premium packaging.

The minimum order levels and minimum order quantities depending on the material and the complexity have great impacts on the cash flow and inventory. Usually standard materials are at lower minimums and specialty or sustainable materials need to be bigger orders. In making material decisions, the brands have to trade-off the inventory risk with the per-unit costs.

Short-term cost increases may be justifiable in the long run brand value considerations. Research always indicates that the quality of packaging affects perceptions of the brand whereby a high quality packaging will attract a higher price and customer loyalty. Environmental responsibility can be used to influence brand differentiation and consumer preference, especially in younger audiences.

Case Studies / Real-World Examples

Nature Valley transformed the packaging of granola bars by replacing the usual boxes with the usage of recyclable paperboard with a clear message on sustainability. The transition raised the prices by about 12 percent but received favorable consumer feedback and contributed to the brand being naturally positioned, which resulted in the gains of the market share that would be more than compensated by the packaging expenditure.

The Special K by Kellogg repackaged their product into lighter materials, and better packaging structure, which required 15 percent less material and did not compromise protection or shelf attractiveness. The program produced a lot of savings on costs and helped achieve corporate sustainability objectives as well as enhance the environmental image of the brand.

Small small crafted cereal brands such as Granola Kitchen have managed to differentiate with the help of kraft paperboard packaging, which accentuates hand-made quality and environmental sustainability. These brands are priced high in a bid to attract premium prices in the market, albeit at increased packaging costs, and achieve customer loyalty by choosing genuine and sustainable packaging options.

These illustrations show that an effective packaging innovation must be aligned between the selection of materials, positioning of the brand, preferences by the target audience, and the goals of the business. Firms that carefully consider such factors usually enjoy positive returns on packaging investments.

Tips for Working with Packaging Manufacturers

During the interaction with the packaging manufacturers, demand specifications of the material in detail such as basis weight, caliper thickness and performance peculiarities. These technicals are understood so as to make sure that the choice of material will achieve your desired strength, printability, and cost objectives.

Enquire on minimum order quantities, lead times and upfront cost of set up so that one does not be taken by surprise when planning the project. Several manufactures have sample programs, where one can test various materials and printing methods and commit to complete production runs later.

Action Ask mockups or prototypes to be reviewed on structural integrity, printing quality, and the overall appearance. These samples show the performance of the materials under real life conditions and are used to show the problems that may arise at an earlier stage prior to the start of production.

Ask about the sustainable materials and certifications. A vast number of manufacturers have grown their green products but they might not serve as advocates. Make it clear what you want to be sustainable and manufacturers will offer you the right options.

Talk in the testing procedures of durability, print quality and shelf life specifications. Best manufacturers are expected to provide their advice on the best testing standards and practices to apply in your application and market needs.

Conclusion: Choosing the Best Material for Your Goals

A right choice of cereal box material involves a compromise of several factors such as cost-related issues, brand image, sustainability and functionality. The high quality materials will contribute to the high brand perception and can contribute to higher retail prices whereas low-end materials allow the company to remain competitive in low-cost markets. Environmental issues are becoming more and more important regarding consumer preferences, and sustainable material usage is an important tool in long-term brand building. Functionality is still the most important – the packaging should ensure that it is sufficient to protect the product, but offer suitable shelf life and convenience to the consumer.

You can think about creating a framework of priorities based on which you have to weigh your particular priorities: give cost, sustainability, premium positioning, and functional requirements a relative priority and compare material options with these points. Experiment with marketable options using sample programs and consumer surveys before final decisions. It should be remembered that the choice of packaging has lasting effects on brand image and positioning at the market which makes the careful assessment of the choice valuable, despite the fact that it interrupts the early launch.