Making the wrong decision will cost your company thousands of dollars in spoiled merchandise, unsatisfied clients, and a lost opportunity to establish your brand. The appropriate packaging is not just a box; no matter the business you are starting, whether it is a skincare luxury, moving electronics across the globe, or trying to make your product unboxing a memorable experience, it is the first physical touch of the brand, the protector of your product, and can be a crucial element in customer experience and sustainability.

The issue is that not all businesses and consumers know the underlying differences in box types and make poor choices that cost them money, damaged goods, or insufficient presentation of the brand. Others buy costly rigid boxes when they have basic shipping requirements, whereas others use feeble folding boxes when their merchandise needs to be highly secured.

This is a guide that will reveal the key categories of boxes, their sub-types, when to apply each type, and practical advice on how best to choose the one that best suits your needs. At the end, you will know how to choose the packaging that is the most effective protection, presentation, price, and sustainability.

Major Categories of Boxes

Folding Cartons

Definition & Key Features

Folded cartons are a paperboard box that is folded into shape using a lightweight and flat folded box. These are universal containers, which are usually produced using solid bleached sulfate (SBS), solid unbleached sulfate (SUS), and recycled paperboard. They are cost-effective, moderate strength, and provide great printability, and are therefore ideal in the retail display and in consumer products. The material thickness tends to be between 12 and 24 points, which offers sufficient protection but is not too expensive.

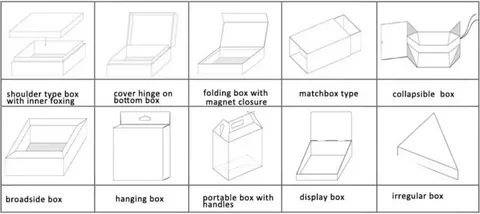

Sub-types & Styles

Straight Tuck End (STE): The top and bottom flaps tuck in a similar direction. The design is easy to assemble and provides a good level of security, and is ideal when used in cosmetics, pharmaceuticals, and food products. The biggest strength is that it has a tamper-evident close, although it might not be appropriate when dealing with very heavy objects.

Reverse Tuck End (RTE): The bottom and top flaps tuck in the opposite direction, offering better security and the look of higher quality. It is usually employed on luxury goods such as perfumes and expensive electronic accessories, but it is a little more complicated to put together.

Auto-Lock Bottom: An automatic locking system is provided at the bottom of the product, and there is no need to use glue or tape on the bottom. The style is also perfect when it comes to retail packaging and e-commerce, as it may be assembled fast and has a good closure, but might be slightly higher because of the tricky die-cutting involved.

Gable Top: Looks like a milk carton that has a peaked layer and a handle attached to it. The style is popular in food packaging, gift items, as well as promotional products; it offers excellent portability and shelf appeal, but has a disadvantage as far as stacking efficiency is concerned.

Window Cartons: They have clear windows made up of plastic to display the product inside. These are ideal boxes to use in the case of toys, baked goods, and consumer electronics, as they increase the visibility of the product, but they can affect the structural integrity of the item to a minor extent.

Use-cases & Examples

Folding cartons are ideal in retail spaces where shelf value and economical conditions are the most important. You can find them packing breakfast cereals, cosmetics, and even over-the-counter drugs, and accessories and cases on your smartphone. They are especially suitable for products that require a medium level of protection during transportation and storage, and use of attractive presentation at the point of sale.

Which Businesses Benefit Most

Folding cartons are preferred by retail brands, online companies that deal with the delivery of lightweight goods, food producers, cosmetics companies, and pharmaceutical manufacturers. They are useful in particular with the companies that are required to strike a balance between the influence of branding and spending on it, when shipping volumes are great and the products are not very fragile or expensive.

Rigid Boxes (Set-Up Boxes)

Definition & Key Features

Set-up boxes, also referred to as rigid boxes, are pre-assembled boxes constructed of high-density chipboard of high density and coated in decorative paper, cloth, or special material. These boxes do not change their structure and have more strength and durability as well as high aesthetic value. The average building is made with 1.5mm to 3mm thick chipboard, which gives it a remarkable crush strength and a high touch that instantly suggests quality and worth.

Sub-types & Styles

Magnetic Closure Boxes: Have an inbuilt magnet to the closure flaps giving a satisfying snap-shut experience. These are ideal with luxury products such as jewelry, high end electronics and high quality gifts as they have a very easy opening and a tight closing though adding to the cost of manufacturing.

Drawer Boxes: These were designed in the style of a drawer with a tray that was sliding. They are best suited to jewelry, watches, and collectibles, giving them a nice reveal experience and great organization, but with high manufacturing tolerances required.

Hinged Lid Boxes: Have a hingeed on top piece of a lid that is permanently attached just like a cigar box. They are used in common packaging of gifts, luxury items and keepsake but might in turn be more complicated to produce since they are durable and reusable.

Shoulder Boxes: These are made up of a bottom part and a distinct lid and the lid extends over the bottom part like a shoe box. These boxes are popular as apparel, shoe, and storage items, and are less expensive than other more rigid materials, but do not provide the same high-end opening experience as competitors.

Cylinder Boxes: Round rigid boxes that are ideal with bottles, posters and special product shapes. They are available with great protection of cylindrical objects and distinctive shelf space, but they can be difficult to ship and store because of shape.

Use-cases & Examples

The luxury market is dominated by rigid boxes where one can find high end jewelry and watches and also the high-end wine and spirits. They are utilised by technology companies as flagship products such as smartphones and headphones, as well as by fashion brands as special edition products and gift sets. They are also used as corporate, promotion, and keepsake products.

Which Businesses Benefit Most

The finest examples of rigid boxes are in luxury brands, jewelry manufacturers, high-end electronics producers, wine and spirits producers, businesses that are specialized in creating memorable unboxing experiences. They are especially useful when the packaging itself is also part of the product value proposition and when there are high chances that the customers will reuse or retain the box.

Corrugated Boxes (Shipping Boxes)

Definition & Key Features

The corrugated boxes are made of fluted corrugated material that is enclosed between a flat linerboard, resulting in a lightweight and extremely strong structure. The fluting cushions and insulation do not affect its structural integrity during shipping and handling. These boxes come in single-wall (3-5mm), double-wall (6-7mm), and triple-wall (15mm) models, and can be tailored to nearly any shipping requirement at an affordable price and without being harmful to the environment.

Sub-types & Styles

Regular Slotted Container (RSC): This is the most common type of shipping box, which has 4 flaps on the top and bottom of the box that overlap in the middle on folded. These boxes are very affordable and wide-range boxes that can be used in general shipping, with the need for some tape to ensure a safe seal.

Full Overlap Container (FOL): It has flaps that fully overlap when closed, giving it additional strength and protection. They are ideal when shipping heavy items and internationally because they consume more material and are a bit more expensive than RSC boxes.

Half Slotted Container (HSC): Is a container with a bottom, but no top flaps, which is supposed to slide over products or can serve as trays. Usually used in automotive component applications, large electronics, and industrial applications where it is necessary to have top access.

Die-Cut Boxes: Corrugated boxes that are made into certain areas to fit particular products. Ideal when it involves oddly shaped products, products that are fragile, or those that cannot be optimally protected by conventional boxes. They will have a better fit and protection, but will need special tooling.

Mailer Boxes: Speechless. Only lightweight corrugated boxes intended to be used in e-commerce shipping that are easy to fold and have an easy time closing without the use of tape. Perfect for clothing, books, and other small electronics with good protection and low shipping costs.

Use-cases & Examples

The largest part of global transportation requirements (Amazon parcels to transporting industrial equipment) is done with corrugated boxes. They are necessary in e-commerce businesses, manufacturers delivering to distributors, moving businesses, and any business that requires product protection that is reliable and affordable in terms of cost.

Which Businesses Benefit Most

Corrugated packaging has the most users in e-commerce retailers, manufacturers, distributors, subscription boxing, and the shipping of heavy or fragile items. They are especially useful when the cost of shipping and security is one of the main factors, and the packaging does not need to fulfill any important branding or display purpose.

Comparative Factors & Decision Criteria

In choosing the appropriate type of box, there are a number of sensitive factors that should be put into consideration in order to achieve the best performance and cost efficiency.

Durability & Strength: Danone Box remains strong and durable, depending on the type of box. Corrugated boxes have high crush and impact strengths and are therefore suitable for the transportation of heavy products or hard handling. Rigid boxes have good crush strength on edges, and they do not collapse under pressure, just right in cases where the choice is a luxury item that will be delivered in perfect condition. There is enough protection offered by folding cartons to lightweight products, but they might not be able to endure heavy impacts or water.

Cost factors Cost aspects entail short-term material costs and long-term value. Folding cartons are generally the cheapest per unit, particularly in large quantities, and as a result of this, they are best suited to consumer goods with narrow margins. Corrugated boxes offer a good balance of cost and protection, but the prices are highly variable depending on the wall thickness and customization. Hard case boxes have high prices, but may justify it with the improved brand image and customer experience.

Branding & Aesthetics There are significant variations in the Aesthetics and Branding capabilities between options. The quality of printing and finishing is excellent, and folding cartons can also be used to work with high-resolution graphics and specialty finishes. The rigid boxes have an unparalleled luxury factor and feel, and they accommodate high-quality materials such as soft coating and foil stamping. Corrugated boxes used to be more functional than aesthetically pleasing, but they can now be used to achieve branded shipping experiences, with high-quality printing.

Sustainability & Eco-friendliness Environmental Impact: Sustainability & Eco-friendliness: Basing decisions on packaging on sustainability and eco-friendliness. Any of the aforementioned box types can include recycled material, with corrugated boxes including 70-90 percent of recycled content. Folding cartons are made of renewable paperboard and can be highly recycled. Although consuming more resources, rigid boxes can be reused and can be made with greener adhesives and coverings.

Size, Shape, and Dimensional Considerations. Dimensional, Shape, and Size issues influence the product protection and shipping efficiency. Corrugated boxes are highly flexible to custom sizing and can be customized to shipping container sizes. Folding cartons are suitable in standardized retail sizes, but are effective for other sizes of products. Rigid boxes are best for making uniform, high-quality displays, but might be less adaptable in regard to size change.

Shipping & Logistical Considerations: Total packaging costs can be highly subject to Shipping & Logistical Considerations. Corrugated boxes are created to be shipped easily, stacked, and handled. Folding cartons are transported in flat form, which maximizes transportation efficiency, and then assembled. Rigid boxes are already assembled, and they take up more space in storage, but no assembly time is needed, and there is no assembly cost.

Tips for Best Box Choice

It is desirable to develop a systematic method of packaging choice to achieve the best results without making expensive errors.

Begin with the creation of a detailed checklist when talking to packaging suppliers. Inquire on the minimum order quantities, lead time on custom orders, finishing options, and structural testing options. Ask them how they have worked within your industry in question and whether they can give samples and prototypes. Know how they control their quality and how they can increase production when your company expands.

The pitfalls are usually related to the underestimation of the significance of the correct sizing, which results in higher shipping expenses and insufficient protection. Most businesses also fail to consider the overall cost of ownership as per-unit prices are considered, yet assembly time, storage space, and efficiency of shipping are not taken into consideration. The other common error is that of adopting packaging based on the decision of the competitors without the need to consider your specific product needs and your brand positioning.

You should have prototyping and testing as part of your packaging choice. Ask for samples of possible alternatives and perform drop test, compression test, and actual shipping tests. Unboxing experience would be tested with real customers, and feedback would be received on the functional and emotional reactions. Take into account seasonal differences in shipping conditions and the performance of different types of boxes in different weather conditions.

The issue of sizing and tolerance must be considered, paying proper attention to product fit and efficacy during shipping. Provide sufficient room to allow protective cushioning with minimal surplus capacity that will add to shipping expenses. Think of the product’s orientation in shipping and the need for extra internal packaging. Depending on manufacturing tolerances of both the products and the packaging will also help to make sure that they work well together.

The choice of finishing and printing may affect the price and brand influence greatly. Know the constraints of each type of box in terms of print quality, color accuracy, and specialty finishes. Look at the impact of premature finishes on the recyclability and whether the premium finishes fit your sustainability objectives. Test the longevity of various finishes during handling and transportation.

Trends & Innovations

Consumer expectations, sustainability concerns, and technological advancements are the factors that have changed the landscape of the packaging industry, with biodegradable and compostable substances becoming more and more popular. Coatings made of plants will replace the usual plastic barriers, and the packaging covers made of mushrooms will replace the foam cushions.

Water-based inks and adhesives are becoming the norm, and now even programs are being developed to recycle specialty packaging materials using closed-loop methods. Smart packaging is being integrated to transform boxes into interactive brand touchpoints rather than their simple containers. Product information, authentication to verify that the product is authentic, and access to digital information will be done by using QR codes.

NFC tags can easily fit the mobile experiences, and the possibilities of augmented reality can deliver unboxing experiences. Minimalist and high-end design is also experimented with by other businesses and can reflect the shifting aesthetic values and environmental awareness of consumers. White space and minimal, pristine design styles are fashionable, but luxury experiences are achieved through good quality of textures and finishes without excessively using different materials.

Customisable and reusable, modular packaging systems are appealing to the modern consumer with an environmentalist mindset who appreciates choice and longevity. Packaging choices are increasingly open to sustainability accreditation and regulatory considerations. Forest Stewardship Council (FSC) certification provides the guarantee of responsibility in sourcing, and Cradle to Cradle certification analyzes the overall lifecycle impact. The long producer responsibility policies in various regions are also developing technology in recyclable and biodegradable materials to make the industry more in line with sustainable solutions.