Introduction

In a current competitive business market, your product packaging can or will make or break the success of your product. On top of being a container with your products, packaging has a direct effect on the cost of production, the environment, the cost of shipping, and, arguably, the initial perception your customers will have of your brand. Be it that you are starting up with a high quality skincare brand or selling snack foods to consumers in various parts of the world it is important to know the underlying differences between rigid and flexible packaging in order to make sound decisions that will meet the targets of your business.

Rigid packaging are containers that do not change shape or structure depending on the contents contained in them, like glass bottles, metal cans, hard plastic containers and strong paperboard boxes. On the contrary, flexible packaging refers to the materials which can be bent, folded and shaped to the content, such as plastic films, foil packets, paper bags and multilayer flexible materials. To manufacturers, retailers, and even conscious consumers, understanding these differences is crucial in maximizing product security, cost-effectiveness, and environmental differences.

What is Rigid Packaging

Rigid packaging is the classical form of product containment where the containers have a pre-established shape and structure that does not change during the lifecycle of the containers. These packages are made to withstand deformation when subjected to the usual handling conditions and allow their contents to have a stable and protective environment.

Glass containers such as bottles and jars, metal elements such as aluminum cans and steel containers, hard plastics such as PET bottles and polypropylene containers, and rigid paperboard used in boxes and cartons are the most frequently used materials in the rigid packaging. The use of each material introduces certain properties that predetermine its use in specific applications and types of products.

Major peculiarities of the rigid packaging revolve around its outstanding strength and form-holding power. These containers are superior in terms of preserving their shape throughout transportation, storage and when used by consumers so that the product appears consistently on retail shelves. The safety features of hard packaging are especially remarkable and introduce better barrier protection against physical damages, contaminations, and environmental hazards, like light, moisture, and oxygen. This structural stability also allows it to stack efficiently and use the storage space effectively in warehouses and retail settings.

What is Flexible Packaging

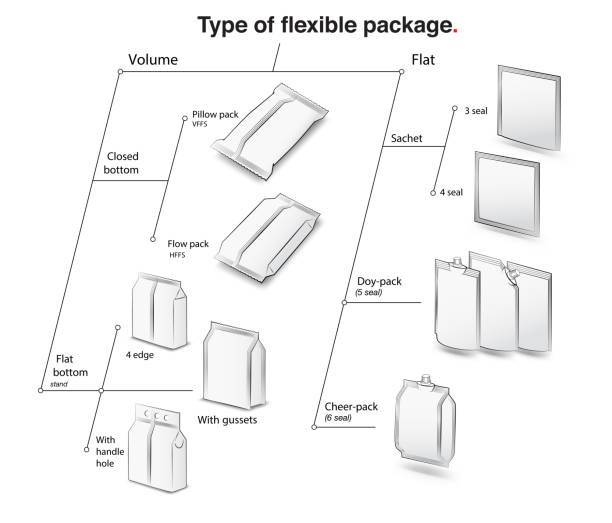

Flexible packaging is a contemporary flexible means of the product maintenance that has transformed many industries in the last few decades. This type of packaging is based on the materials and structures that can be easily bent and folded and declared to the form of their contents without losing their protective and functional characteristics.

The list of materials utilized in flexible packaging is very diverse and includes plastic films based on polyethylene, polypropylene, and polyester, as well as aluminum foils in order to provide the product with more efficient barrier properties, different types of plastic bags and pouches, and even paper-based flexible materials with or without additional plastic or foil coverages. These materials are often being taken as multilayers in laminates to attain certain performance features like moisture resistance, oxygen barriers or heat sealability.

The most notable features of flexible packaging are that it is lightweight, which makes it not only expensive to transport in terms of shipping but also not harmful to the environment. Its versatile characteristics enable it to easily conform to the shape and size of products, and the flexibility of its folding and compressing characteristic helps it to occupy less space when stored before loading. A variety of flexible packages also have a convenient option of easy open seals, resealable tops to keep the product longer, or one use packages that do not require further dispensing tools.

Pros & Cons: Rigid Packaging

Advantages

The benefits of rigid packaging are quite impressive and it has many strengths that render it the choice of many high-end and specialty products. The outstanding protective features are perhaps the greatest advantage, which gives better protection against physical damage, crushing, and impact in shipping and handling. This renders rigid packaging to be the best in terms of protection of delicate products like cosmetics, electronics, and glass ware where the highest level of protection is necessary in the entire supply chain.

Rigid package product It gives a high perceived product value and brand image due to the high perceived value and solid impression of the product. Since rigid containers are seen by consumers as a sign of better quality and luxury, this type of packaging comes in handy when it comes to premium positioning. Also, stiff packaging is usually superior in light, moisture, oxygen and other environmental protection against damages that may interfere with integrity of the product, and is therefore needed in sensitive formulations and product with a long shelf life.

Structural stability of rigid packaging is also a good printability and labeling surface that allow high-quality graphics and branding aspects to be used to increase shelf appeal and marketing effectiveness.

Disadvantages

Even with the benefits of rigid packaging in terms of protection, it is important to note that it has several significant disadvantages that should be looked into seriously. The weight aspect is a major drawback as larger packages will raise transportation and shipping expenses, carbon footprint of transportation, and handling challenges of the supply chain. The fixed dimensions and impossibility of optimizing the use of space also make storage and transportation more expensive.

The cost of using rigid packaging is usually more expensive because the material used and the manufacturing process requires more money. Environmental costs may also be very great especially in the use of materials such as glass and metal which involve energy consuming production processes. Moreover, the hard packaging material usually occupies more storage areas during storage and waste disposal, posing a challenge to the waste management system.

Pros & Cons: Flexible Packaging

Advantages

Flexible packaging provides a significant cost reduction in various points of the supply chain such as the cost of materials will be reduced as well as delivering reduced shipping costs because of lower weight. The space efficiency is impressive–flexible packages can realize up to 85% space savings over rigid products when empty and their capacity to fit product shapes will reduce wasted space in storage and transportation.

The potential of customization using flexible packaging is almost unlimited, and it allows using unique shapes and sizes and various design features to provide the unique distinction of the brand. The printability of the flexible films frequently enables vivid, high-resolution graphics on the whole package. Flexible packaging in most cases has a less imposing environmental impact because it uses less material and results in less transportation-emission emissions.

The convenience factors are the possibility of having portion control, easy dispensing, and the facility of preparing packages that can be easily opened, closed, and stored within the consumer settings.

Disadvantages

The major drawbacks of flexible packaging revolve around the fact that they offer lesser protection than the rigid ones. Goods that are placed in flexible materials can be prone to physical damages, puncturing, and crushing when handling. Barrier properties may be harder to attain especially with products that need to be preserved against oxygen, moisture or light.

Weaknesses Durability in flexible packages This is because flexible packages cannot take rough handling as compared to rigid containers, thus losing products or causing dissatisfaction to customers. The transmission of odors or the movement of flavor is also a problem that may be brought about by some flexible materials and may be inconvenient when used in food and beverage applications. Perceived value might be reduced with consumers who subconsciously relate the flexible packaging with lower quality or commodity products.

Use Cases & Examples

The cosmetics and personal care industry and the glass jars and bottles commonly used in the industry represent an example of industries and products that use rigid packaging as it helps to project the image of luxury and keep the formulations sensitive to light and to air. Food industry also depends on hard packaging of goods such as glass jarred of food stuffs such as sauces, preserves and premium foods which have the advantage of long shelf life and high presentation value. Rigid packaging is applied by the electronics manufacturers to safeguard delicate components during transportation and offer professional unboxing experiences which will further support brand quality.

Medications that need a specific dosage, evidence of tampering, and waterproofing are the drugs that pharmaceutical companies rely on a rigid packaging. Glass bottles have been associated with wine and spirits industries to provide its product protection as well as its traditional and premium qualities that consumers want.

In the snack food market, the most common packaging is flexible packaging, lightweight, and resealable pouches that offer convenience with regard to ease of packaging and consumption, as well as the ability to offer freshness and reduce transportation costs. Personal care products including shampoo sachets and travel sizes are beneficiaries of the portion control aspect of flexible packaging and a decrease in packaging waste. Flexible packaging is also being adopted to provide convenience and saving costs by pet food manufacturers whilst ensuring that the product remains in its fresh state because of the high quality barrier technology.

Hybrid packaging systems are the systems that incorporate both solid and soft components in order to maximize the benefits. An illustration is the case of many products utilizing rigid primary packaging to protect the item and provide high-end packaging, and utilize a flexible secondary package to deliver goods effectively. The traditional hybrid is cereal box with rigid paperboard to give the box structure and shelf presence and flexible inner lining to protect products and keep them fresh.

The success stories in the real world involve large beverage brands that have switched to lightweight rigid packaging and incurred less shipping expenses despite holding onto their high-end status. In the same vein, numerous personal care brands have extended to adopt flexible refill structures whereby high-end rigid primary packaging is used with low-end flexible refills that attract a green consumer.

Environmental & Sustainability Considerations

The comparison of environmental impacts of the rigid and flexible packaging shows that there are complex trade-offs, which differ extensively depending on the material, use, and end-of-life conditions. The ability to recycle varies greatly across the types of packaging and some rigid materials such as glass and aluminum can be recycled very well whilst others especially the multilayer flexible structures have great difficulty in being recycled.

Glass and aluminum are examples of rigid packaging materials, which can be recycled indefinitely without reduction in quality, and can be recycled repeatedly without losing its qualities respectively. The power consumed in the manufacturing and recycling of these materials is however high. The recycling infrastructure has a well-established number of rigid plastic containers, but contamination and mixed materials may complicate the process.

Flexible packaging has a more difficult environmental image. Although they require fewer raw materials and create fewer emissions in transportation since they are lightweight, the multilayer package designs of flexible packaging cannot be easily separated and recycled through traditional means. Nevertheless, these challenges are being overcome by innovative recycling programs and recycling technologies that use chemicals.

The carbon footprint analysis should be approached at the whole life cycle, including the extraction of the raw material, production, transportation, use, and disposal. Flexible packaging can prove to show benefits in production and transportation stages, as there is a reduction in the material requirements and weight and rigid package can show advantages in product protection and shelf life which will decrease food waste and related environmental effects.

The two categories have biodegradable alternatives that are growing in popularity, with bio-based flex film, and compostable inflexible containers becoming more and more easy to find. Nevertheless, these options usually involve special conditions or infrastructure of composting which might be not so common.

Recent innovations are aimed at coming up with mono material flexible packaging that maintains performance and enhances recyclability, lightweighting the rigid container to reduce material consumption and transportation effect. Flexible packaging based on recycled material is also being investigated by companies as well as reuse models of rigid packaging.

Cost, Shipping & Storage Impacts

The economic issues of packaging selection do not just limit themselves to the material costs of packaging, but include production, logistics, infrastructure concerns that may have a profound effect on the overall profitability. Rigid packaging usually involves higher costs of materials, more complicated processes in production, and higher costs on tools used, and flexible packaging can help to do more efficient production runs and to spend less on set up.

Another important cost difference that exists between types of packaging is shipping weight and volume effects. The use of flexible packaging in comparison with rigid ones can save shipping costs by 40-60 percent because of the reduction of weight and optimization of space. This benefit is more pronounced especially in shipping over long distances or in international distribution where the cost of transportation makes up a significant percentage of the overall product cost.

Storage efficacy influences the retail and warehouse operations. The flexibility of packaging enables it to occupy less space in storage by as much as 90 percent of the volume occupied by rigid containers. This space saving will equate to the reduced warehousing expenses, ease of real estate demands and inventory turnover. Nevertheless, the rigidity of packaging can offer superior stacking and shelfability, which would lead to lower handling costs and retail efficiency.

Other factors that should be taken into account in the total cost of ownership include loss of the product in terms of damage, secondary packaging as well as the cost of disposing the end of life. Although the cost of rigid packaging can be higher, its greater protection capabilities can minimise the loss and returns of the products, which can offset the cost of acquisition.

How to Choose the Right Packaging for Your Product or Business

To choose the best packaging, there is a complex analysis of various related factors that would be much more in line with your business goals and the needs of your product. The first thing to do is to do a careful evaluation of the physical features and protection requirements of your product. Take into account the fragility, sensitivity to environmental characteristics like light, oxygen and moisture, shelf life needed, and special handling needs in the distribution and storage.

First packaging decisions should be made based on product characteristics. Rigid packaging tends to be better in providing protection to the fragile items, whereas the stable products can perform well in the low-cost alternative flexible packages. When products have a long shelf life, the extra barrier properties of rigid packaging or multilayered barrier flexible structure are needed.

Packaging choice is equally dependent on branding and customer perception issues. The perceived value and high feel of rigid packaging and the ease of use of flexible packaging can be in the interest of premium products and convenience-oriented products, respectively. When considering the packaging, take into account the preferences of your target demographic, as well as their shopping habits and their environmental awareness.

Cost factors need to include the overall cost of ownership as opposed to material costs. Take into consideration the volume of production because sometimes the rigid packaging has a higher minimum order but has a better unit cost at the higher volume. In your analysis include transportation costs, storage requirements and possible loss of the product. Look at the long-term profitability targets and short-term budget limitations.

Distribution needs and logistics are major parameters that affect the best packaging options. The assessment of your channels of distribution, mode of transportation, storage capacity, and the retail environment needs to be evaluated. Goods shipped over a long distance or having to pass through various points of handling could be better served by the protection of rigid packaging whereas direct-to-consumer companies could focus more on the shipping efficiency of flexible packaging.

The decisions regarding the packaging should have environmental objectives and sustainability obligations in their initial stage. Take into consideration environmental policies of your company, its customers and regulatory needs. Assess end of life conditions, the infrastructure of recycling, and the possibility of packaging reduction or reuse schemes.

Conclusion

It all boils down to the option of rigid or flexible packaging of the product that you are intending to use and find the best balance between product protection, cost efficiency, brand positioning and environmental responsibility. Rigid packaging is effective in exhibiting high standards of presentation as well as the highest protection to the delicate or sensitive products, thus is suitable in luxury goods, pharmaceuticals, and goods with a long shelf life. Flexible packaging has the best cost-saving options, shipping benefits, and flexibility in design and is ideal when dealing with convenience products, lightweight products, and companies that focus on optimization of the supply chain. Instead of treating them as opposing solutions, think how the hybrid solutions can be implemented combining the advantages of both types of packaging to develop solutions that will satisfy all your needs. Do it by seriously assessing your existing packaging as per these requirements, engaging in discussions with your packaging vendors on innovative options as well as trial and error out prototyping with your target audience to ensure the choices made are correct before large scale adoption.