Rigid boxes and magnetic boxes (also known as magnetic closure boxes) are also common in the luxury watch packaging box industry. However, there is no universally optimal decision–the structures are aimed at various priorities of branding and protection, as well as production. Most brands presuppose that magnetic boxes are, indeed, a higher quality due to the pleasing effect of a click close, yet in reality, a more rigid watch box may provide more structural stability, consistent fit, and a long-lasting performance.

The decision on whether to use a rigid box or magnetic box as the packaging of the watches must consider the structure, brand perception, protection, and manufacturability as a unit factor. The best choice occurs when you know the behavior of each type in actual production runs, shipping, display in the retail area and customer hands-on not based on looks only.

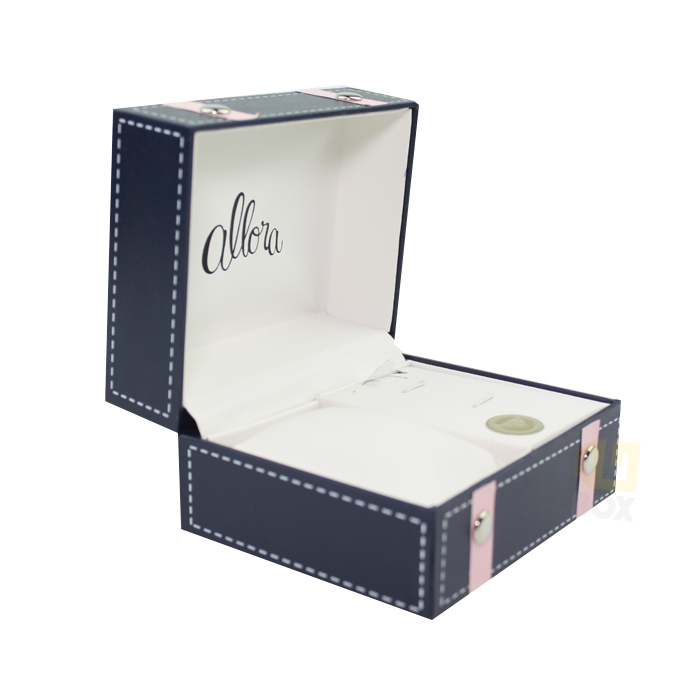

When considering alternative packages, an initial reference to playing in watch brands is to have a good base in the area of custom watch packaging helps align the outer box with the complete system.

Why Box Structure Matters in Watch Packaging

Watch packaging cannot afford to simply look good on a shelf, it needs to safeguard a high price, fragile product during global shipping, storage and numerous openings during repeated openings in the process of reaffirming brand positioning.

Outer box design has a direct relationship on the crushing or denting hardiness, the accuracy of the part positioning during the assembly process, and the desired feel of the packet after years. An inappropriately selected design may result in misaligned lids, lax covers, or worn out look after only a few uses undercutting the high image watches that watches are based on. The structure is not a secondary of graphics or finishes, but it is the structure which can either help or hurt the entire experience.

Rigid Box Construction and Practical Characteristics

Since they have been running their production of premium watch clients, rigid boxes are made of thick greyboard (goods measured at 1.5 3mm) and enveloped in specialty paper or leatherette that are characterised by the stability and predictability of the rigid boxes.

The boxes are typically 2 part (base + lid) or hinged without using any other systems to commit to closure. The natural rigidity of the thick board allows the walls of the structure not to bend, the corners not to become rounded, and placement on top of other objects in warehouses or retail displays does not lose its functionality even with average weight.

Its strengths are that it is very consistent in structures when used in bulk quantities, it is unlikely to warp when exposed to humidity changes, and the watch was well-covered and the inserts as well.

Limitations Restrictions revolve around the opening process: it is simple and classic – pull off the lid or push the hinge – without the feel of the box that most people relate to the luxury unboxing the process of selecting thechoosing the right box for luxury watches.

| Aspect | Description |

| Structural stability | High |

| Opening experience | Simple and traditional |

| Protection level | Strong |

| Typical application | Classic and premium watch brands |

Magnetic Box Construction and Practical Characteristics

Building Construction and Practical Characteristics Building Magnets and Magnetic Boxes.

Magnetic boxes combine embedded neodymium magnets (which are usually concealed in the lid flap and base), to form a gratifying, automatic snap-shut. Rigid greyboard is still being used as the core, though the construction takes into account accurate cutouts, extra adhesive layers in which to place the magnets, and in many cases flaps are reinforced to allow consistent positioning.

Strengths points are the high-quality and interactive opening: the soft pull-apart resistance and the clean “Click” closure not only increases the perceived luxury but makes the unboxing worth loving – and that is a characteristic of watch collections targeted at the gift market or lifestyle.

Limitations These limitations manifest themselves in manufacturing and application: the magnets require tighter tolerances of ideal alignment; a slight change in board thickness, stretch of paper, or pressure of the assembly can result in imperfect lidding or even the inability to close lids smoothly. They also react more to the effects which may cause the magnets to be displaced in the course of opening them repeatedly.

| Aspect | Description |

| Structural stability | Medium to high |

| Opening experience | Premium and interactive |

| Protection level | Medium |

| Typical application | Gift-oriented and lifestyle watch brands |

Brand Perception and User Experience Differences

This is because of the opening of a box, which influences first impressions more than the majority of brands have initially believed. A magnetic watch package form offers that same deliberate, feeling experience a packet of watch where the lid is pulled open, only to find a magnetic force pushing it back is simply the experience one expects in a packaging of a watch, and seems well aligned with modern-day experience-driven brands. By contrast, a traditional hard box sends out a message of silent confidence and eternal dependability respecting the heritage or low profile luxury.

This should be an option that is motivated by brand identity. When your watches focus on the story and the emotional bond, the interactive feature of a magnetic watch box may be used to enforce this story. In the case of brands based on precision engineering and quality durability, the no-nonsense obtuseness of a rigid watch box can be more authentic. Read more on how packaging influences watch brand perception to see how these subtle cues accumulate into overall positioning.

Protection Performance in Real-World Handling

Protection is not just about aesthetics; it is also about what will occur when the package goes through the logistic networks, languish in the hot warehouses, or even when it goes through the hands of several people before it reaches the customer.

Rigid boxes are typically better in this case: thick and uniform walls distributed the pressure, which causes the possibilities of denting or crushing corners during the transportation. The watch and custom inserts (EVA foam, formed pulp) are firmly fixed, remain in place, even in cases with the outer carton receiving impacts.

Magnetic boxes are very protective initially but as lids are sensitive to their alignment, they may shift detachments over a period resulting in either dust entry or shift in the hardware. Rigid structure is sometimes lenient in high volume e-commerce or international shipping.

Production Complexity, Cost, and Lead Time Impact

Magnetic boxes also most often involve additional procedures: the positioning of the magnets precisely, die cutting recesses, die cut flaps, die cut extra die-cuts to reinforce the flaps, and extra and more intense QC to identify alignment problems. These complicate, reduce first-pass production yield on certain runs, and increase set-up time, particularly of complicated processes such as foil stamping or soft-touch lamination.

Compared to the rigid boxes, they have a less complicated workflow and fewer variables, resulting in increased consistency, increased predictability of prices and a reduced lead time on re-orders. This distinction is significant to brands that have to transition out of prototypes to thousands of units. To get more details on lead time, see our guide on watch box production lead time.

Box Structure Selection Within a Complete Packaging System

No box exists in isolation. The exterior design should fit perfectly with interior cushions, printability, surface finishing, and even logistic needs. A magnetic closure may be beautiful to look at but difficult to place an insert where it is not tolerated; a rigid hinged design may be easy to assemble but restrict some aesthetics.

Always trace the box type back to the entire system early-structure has an effect everywhere down the line, tooling cost to ultimate QC pass rate.

How OEM Manufacturing Capabilities Influence Box Selection

Not all factories are equally good with both types. Systems capable of doing good magnet jobs with high accuracy and multi-stage test programs can scale-built crystal-clean magnetic boxes but other systems are usually well-accomplished with simple rigid configurations and very few variables.

When in early discussions with your OEM partner, you are able to see what is realistically within your schedule, budget, and quality considerations. This is one of the most prevalent causes of overrun or underperforming projects. Learn more about the full process in how OEM watch packaging projects are manufactured.

Conclusion — The Better Box Is the One That Fits the Brand System

Rigid boxes and magnetic boxes have their own significance in the packaging of watches. The more preferable variant is the one that is more consistent with brand positioning, the needs of protection, and the reality of production, not merely the appearance.

Assess your priorities: Is it the maximum structural safety and fidelity of production that your customers demand, or is it the interactivity of the unboxing experience that facilitates a better customer experience? Compare them to actual manufacturing limits and the argument comes out distinctly. This balanced opinion makes the best packaging choices, so this box will not rival the watch inside, rather, it will be in their favor.