Meta Description: Learn the most recommended cardboard printing processes that should include solid color implementation and be done on printing on custom packaging cardboard boxes like flexographic, digital and lithographic printers, which are known for their cost effective solution . Find out information about ink types, prices and quality when it comes to professional packaging solutions.

Custom printed cardboard boxes have seen a surge in demand these days in the highly competitive business world that requires such things to ensure brand recognition, customer satisfaction, and customer interaction. As a start-up or an established business, learning about the different ways of printing methods that you can do on cardboard packaging, including custom packaging options. may easily influence the success of your marketing strategy and ease of operations. The guide fills all the gaps of printing on cardboard boxes, whether the analog or the digital method.

Understanding the Importance of Cardboard Box Printing

A shipping box printing may be vital since it helps business owner reach clients and improve the quality of sales in corrugated boxes . The use of customized printed packaging is not out of identification purposes but also in brand awareness, customer experience, and sales quality presentations.

The psychological effect of the well-made packaging cannot be overestimated. Having a box with raised image areas professionally printed for product packaging will leave a good first message to the customer, fulfilling all your printing needs, that will make him or her feel good toward your brand and product. This first point of contact can make or break a client to whether he or she will be a repeat-purchaser or give a referral to his friends or relatives.

Primary Printing Methods for Cardboard Boxes

Flexographic Printing: The Industry Standard

Flexographic printing is flexible in nature and works best on printing projects accompanied with a short turnaround. This process enjoys a monopoly in the cardboard packaging industry considering its cost effective flexibility and affordability in making bulk printing orders.

Flexography Flex graph printing uses flexible relief plates made of flexible rubber or photopolymer plates material. It is the stage of the transfer of the ink showing on the printing plate to the surface of the cardboards by using a number of rollers. Because of such precise transferring, there is uniform distribution of the high quality inks and clear reproduction of the images in thousands of boxes.

The method is best when it comes to creating solid colors, textual designs and simple graphics. The food packaging to e-commerce shipping industries are the industries that apply flexo printing on their cardboard box needs. The fact that the method is capable of different cardboard weights and textures during substrate passes is one of its features that makes it rather suitable to corrugated materials.

Digital Printing: Modern Flexibility and Precision

The most popular currently growing segment is digital printing, increasing 13 percent annually; this too makes it an arising selection when it comes to the printing method for custom printing of cardboard boxes. This technique has its unequalled flexibility that can be produced in small to medium print runs and complex designs, resulting in high quality images .

There is no use of printing plates in digital printing, and, therefore, the immediate start of its production when printing onto cardboard boxes . This is an added benefit in terms of reduced minimum order quantities and low set up costs for the printing method . The companies are able to experiment with their designs, make a special packaging to meet a particular customer or create a series of boxes with hardly an investment.

The technology facilitates variable printing and every box can contain a different information; customer names, addresses, or personal messages. This possibility presents new avenues of direct marketing and interacting with customers.

Lithographic Printing: Premium Quality Results

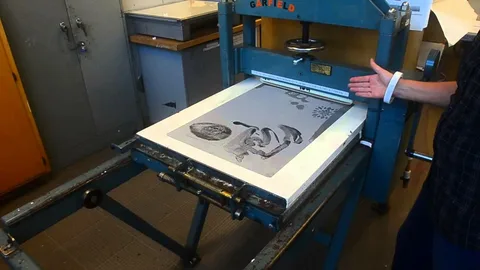

The defined standard of high-quality printing on cardboard box is the lithographic printing or litho printing, otherwise called offset lithography. High image sharpness and quality images are made possible through using aluminum plates in offset printing to create durable prints and highly advanced ink transfer mechanism.

The mechanics entail transferring the picture onto the printing plate onto the rubber blanket and finally, on the cardboard surface indirect transfer. This indirect method of transferring is called offset and provides non-variable distribution of ink and avoids wear on the plates, and is suitable on large print runs where the same quality on an individual print is a prerequisite.

Lithographic printing enjoys its best results in printing of photographic images and bold graphics and complicated graphics as well as designs where color matching is essential. The recipe is compatible with a diverse variety of specialty inks, such as metallic and fluorescent colors, thus the designers have a large variety at their disposable in cardboard packaging.

Screen Printing for Cardboard Applications

A perfect choice to provide larger graphics or solid color to cardboard packaging boxes is screen printing which fits well in small to mid-range print productions. It is an old practice that has its own exclusive benefits when it comes to certain design needs and budget constraints.

Screen printing is the combination of making a stencil (screen) of every color in the image. Through the screen, a squeegee presses the ink on the cardboard surface through a mesh screen stretched tightly . The technique creates bright opaque colors that look splendidly vivid when placed on the natural brown cardboard.

The technique is also very effective when it comes to designs that need thick ink deposits like solid color logos or words which have to be very conspicuous in print. Specialty formulations also inks such as glow-in-the-dark, textured and scratch resistant inks can also be used by screen printing.

Rotogravure Printing: Industrial-Scale Excellence

The ultimate in high volume printing of cardboard boxes involves rotogravure. The technique employs engraved copper cylinders in order to transfer ink to give very durable and transcendentally detailed prints that are perfect packaging materials.

This is done by the laser-engraving or chemical etching to form microscopic cells onto the copper cylinder surface. The cells contain different proportions of ink providing this cell with the capacity to control the density and gradation of the image. The inked cylinder, engraved with information is then rotated in an ink bath, which fills the cells of the cylinder with the ink and then the image is transferred onto the cardboard.

Rotogravure printing gives very good image quality, having smooth gradations and good detail reproduction. The technique is optimal in use in applications that need photographic and mirror quality in packaging i.e. luxurious products, cosmetics and premium foodstuff.

Ink Types and Their Applications

Solvent-Based Inks

Solvent ink includes pigments that are suspended in organic solvents, producing long lasting and well adhesive prints, along with variable data capabilitie . The ink also dyes deep inside the cardboard fibers adding durability to color retention and preventing handling damage.

The formulation also offers high qualities when it comes to glossy or coated cardboard surfaces that other types of ink may not stick. Solventprint/s have quick evaporation drying, which means that they are used in high-speed print jobs.

Water-Based Inks

Water-based inks would be an eco-friendly option of printing cardboard boxes. They are formulated with water being the main solvent thus greatly minimizing the emission of volatile organic compound (VOC) during printing.

The inks go deep into porous surfaces of cardboard papers to make the prints to crew deeply into the cardboard papers as opposed to being on top. This trait creates water based inks especially adequate in food packaging, where there is an issue of ink migration.

UV-Curable Inks

UV-curable ink has its own special benefits where a cardboard is to be printed on that should be very strong and having bright colors using oil based inks . These inks are kept at a liquid state and only require the exposure of the ultraviolet light, where it undergoes an immediate curing effect.

Curing process makes scratches resistant and thus forms a hard layer on the surface that even with harsh handling, the curing process retains colors vibrancy. Another quality of UV inks is that they adhere remarkably well to a variety of cardboard types and are ideal for printing on cardboard boxes that may be difficult to grasp or coated.

Color Systems and Design Considerations

CMYK Color Process

Most cardboard box printing activities revolve around the use of CMYK (Cyan, Magenta, Yellow, Key/Black) color scheme. It is a four-color process capable of replicating all kinds of colors using different mixtures, suitable for art projects of various materials and this set of four primary colors of printing.

Knowledge in the limitations of CMYK will be useful in improving the design of cardboard boxes by the designer. It is most effective when dealing with designs that are optimized to this color space and the designer is unlikely to suffer the surprise of seeing colors go wrong on the screen when they print on the press.

Spot Color Applications

The use of spot colors is beneficial in cardboard box printing where the priority is given to the marketing materials brand and matching the color. These pre-mixed inks provide a precise match of color in various print runs and printing sites, allowing for the inclusion of bar codes .

The common spot color systems are Pantone with standard colors formulations internationally accepted. This uniformity can be particularly helpful to business enterprises that hold strong brand concepts that need distinct color matches in all packaging media, including litho lamination .

Cardboard Flute Considerations

E Flute: Optimal Print Surface

E flute cardboard creates the flattest surface of popular flute types, so it is a great solution in terms of printing with high quality. Its smooth-surface of the fine flute structure absorbs ink uniformly, which translates to the sharp text and clean graphics for your own boxes .

E flute cardboard has a thin profile which makes it suitable to designs involving fine details to be reproduced. But, with less thickness, there is a less cushioning protection and this type of flute is more suitable to use with light or non-fragile items in large quantities .

B Flute: Balanced Performance

B flute cardboard makes a great combination of the printing quality and structural strength. The medium sized flute offers excellent surface smoothness and enough cushioning characteristics in most shipping facilities.

It is an appropriate kind of flute when the design of the product is moderate with regard to the level of detailing and when the business demands good packaging that can both maintain printing as well as protection. The compromise composition leads to B flute becoming a typical choice when there is a need to print cardboard boxes in a general-purpose case.

C Flute: Maximum Protection

C flute cardboard also places much more importance on protection, as it uses flutes of larger size offering great cushioning value although resulting in a rougher print surface. This kind of flutes is suitable when the design is simple, and it needs to be featuring bold items that can still be seen through the patterned surface.

The cardboard used to make C flute has a thick profile hence useful in shipping delicate goods or obtaining products that demand optimal protection. Although the printing quality might be lower than with thinner flutes the protection might not be worth this trade-off.

Cost Analysis and Budget Planning

The cost model of the various printing techniques assists companies to know how to make sound investments in the printing of cardboard boxes, especially when dealing with mass quantities . All have different cost characteristic which apply differently in large and small orders, and complex and simple designs.

There is a wide difference between setup costs in different printing methods. Digital printing involves little set up and it is economical to run small quantities. The setup cost of flexographic printing is moderate but its unit-based price is perfect with medium and large-scale orders for substrate or cardboard boxes . Lithographic and rotogravure printing are more expensive in the setup costs but offer the best unit costs when quantity is very large.

The cost of materials is cardboard, ink and finishing materials. The of higher quality cardboard and specialty inks are more costly but can yield a better print outcome and more sharpened brand perception. Businesses have to tip these factors into their budget and marketing goal.

Quality Control and Testing

Having an effective quality control will identify the consistent quality of the print on all the cardboard boxes. This is done by first color proofing then going to the production monitoring to the final inspection.

The term color proofing deals with setting up mock prints under such conditions as closely as possible to production conditions. This measure determines the possible problems that will be avoided during the actual production to avoid reprints that involve a lot of expenses as well as time wastage.

In production monitoring, there should be frequent check of quality of print, consistence of the color and accuracy of the registration. The current printing plants have automated the facility and monitor these parameters online, thus making the quality control acceptable during the production run.

Environmental Considerations

In matters relating to printing of the cardboard boxes, environmental impact has gained more consideration. UV and water-based inks present less environmental impact than their traditional counterparts when using corrugated cardboard in the use of solvent based inks, making them more cost effective .

The compatibility on recycling impacts on the whole lifecycle of packaging. To ensure that the cardboard retains its recyclability inks and coatings should be soluble with cardboard recycling procedures. This factor affects the choice of ink as well as designs.

Cardboard materials are sustainably sourced and do not interfere with print quality as they also address environmental goals, including those that may require coated screen application . FSC Forest Stewardship council certification of cardboard means the responsible management of forests across the supply chain.

Future Trends and Innovations

Printing industry of cardboard is still under development as new technologies and needs of the market change. Nowadays, the fastest growing market segment is digital printing which is producing an average growth rate of 13 percent per year, minimizing coding errors which means that it has a great potential to grow in the future.

Automation and artificial intelligence enable production to be carried out cheaper and with the same quality. The smart printing can also handle automatically parameters according to live quality response decreasing wastage and guaranteeing structured outcomes.

The sustainable printing is fuelling development in formulations of ink and printing. Waterless printing, bio-based inks are more environmentally friendly without or with improved print quality impression roller.

Conclusion

The type of printing to use on cardboard boxes depends on various things such as quantity of the order to print, design complexity, budget strains, and quality specifications. Most industries use flexographic in the manufacturing of products go to method, which produces good value with medium and large print runs. Digital printing offers unsurpassed small run and complex design flexibility whereas lithographic and rotogravure printing are used when highest quality is required in a specialized application temporary displays. Being knowledgeable with these options can help businesses make informed choices balancing between cost, quality and environmental concerns and succeeding in their marketing goals cereal boxes light sensitive emulsion.