Find out the ultimate guide to types of packaging materials such as cardboard, plastic, glass and metal or environment-friendly packaging. Find out and understand the benefits, difficulties, and various industry uses to offer maximum protection and sustainability of the product.

Introduction to Packaging Materials

The packaging materials provide the necessary link between product production and consumer contentment. In this fast changing business environment, it is imperative that a business would gain knowledge of the vast variety of most popular packaging materials, including recycled paper . which are in the market to ensure that the manufacturers of the product would want to secure their products, make them attractive to the consumers and also consider the sustainability which should be environmentally friendly. Traditional materials used in cardboard and plastic products may be easily changed on the innovative biodegradable models, however, each of them has its own benefits and limitations and these limitations are to be addressed with care.

The Fundamental Role of Packaging Materials in Modern Commerce

The importance of packaging materials could never be underestimated. These consumables, including secondary packaging, are product defenders, knowledge bearers, promotion tools as well as sustainability proclaimers. At the present time, when consumer awareness and environmental awareness have never been higher, it is possible to say that the selection of the material used as a packaging in the packaging industry might play a significant role and influence brand perception, customer loyalty and related success on the market.

Understanding the Importance of Packaging Materials

Product Protection and Safety

The first task of packaging materials is about product protection. Various products need different sources of protection, including cardboard boxes, depending on their level of fragile nature, sensitivity to environmental forces and mode of transport. Electronics are fragile and require cushioning materials such as foam pads and bubble wrap, whereas foods require moisture, oxygen and contamination prevention barriers. Quality packaging material guarantees that its products arrive in top-notch conditions in the market without returns and loss of brand image.

Information Communication and Compliance

Packaging materials are an important communication tool as it provides key product information on product labels, tags and direct printing. Compliance to regulations, lists of ingredients, use directions, and safety warnings also rely on the packaging supplies and material to be able to present information in an easy to see, and lasting manner. Such communication role is even more essential in such an industry as pharmaceuticals and food packaging, as correct information may be a life and death one.

Marketing and Brand Differentiation

Packaging materials are very crucial in competitive markets as far as marketing and brand differentiation is concerned. Rare designs, high quality materials, including most common packaging materials and creative packaging designs can attract consumers and turn them into the memorable experience of the brand. Sensory sensation of packing, its appearance and how good people think it is all adds on the overall brand image and buy decisions.

Environmental Responsibility and Sustainability

Environmental responsibility by the modern consumer is a consideration that is growing among the consumers hence becoming a competitive advantage of using eco friendly packaging materials. Business enterprises that employ recyclable materials like wooden pallets and other packaging supplies show adherence to environment coupled with appealing to the conscious consumer besides enjoying favorable brand relationship. Such a transition to sustainability delivers innovation in the development and acceptance of ancillary packaging materials.

Comprehensive Overview of Packaging Material Types

Traditional Packaging Materials

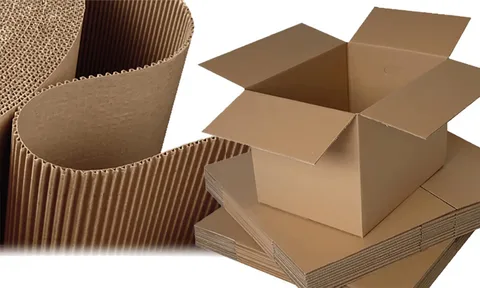

Cardboard: The Versatile Champion

One of the most common and flexible forms of packaging material that can be found in the industry is cardboard. It has products as low as simple shipping boxes made from corrugated cardboard boxes and wooden boxes to high technology custom-built packaging solutions. The cardboard has had a good reputation due to its good balance on strength and weight, cost effective and environmental friendly.

Benefits of Cardboard Packaging including blister packaging :

- Great design/application flexibility Works with every major database

- Better protection of a huge variety of products

- Eco-friendly and 100 percent recycle-able

- Production and customization at low cost

- Awesome branding and information printability

- The lightweight and yet can be of strong structure construction

Challenges of Cardboard Packaging:

- Low resistance to moisture.

- Such products as very heavy products have weight restrictions

- Vulnerability to pressure with enormous strength

- Fungal decay under moist conditions

- Inventory management levels of storage space needs

Plastic: The Modern Workhorse

Plastic packaging includes a number of types of polymers, and to these polymers belong polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). Nevertheless, alternative packaging materials like plastic containers and plastic pallets re so irreplaceable because of such qualities as durability, flexibility, and a protective factor despite the concern over the environment.

Benefits of Plastic Packaging:

- High moisture and chemical resistant properties

- The ability to be light and not subject to impacts

- Clear product-visibility options

- Outstanding inhibitory characteristics towards pollutants

- Low cost mass production potentiality

- Flexible shaping and forming opportunities

Challenges of glass containers plastic Packaging:

- The issue on waste disposal and recycling to the environment

- The effect of petroleum-based production Petroleum-based production has effects on the economy and the environment.

- Issues of consumer perception in the area of sustainability

- Mixed polymer recycling complexity

- The Possibilities of chemical leaching by some applications

Glass: The Premium Choice

Glass packaging forms the higher end of packaging material. Although glass containers are more costly and heavy than other packaging alternatives, including tin cans, they have a better consumer attraction and protection of a product, especially when dealing with medicine bottles and luxurious products.

Benefits of Glass Packaging:

- Perfect gas and moisture proofness

- Those that are chemically nonreactive to avoid infections Gross anatomy Many chemical and physical properties Chemically inert properties Which prevent contamination Gross anatomy Many chemical and physical characteristics

- Can be recycled to 100 percent without loss of quality

- Classy looks and shopping values

- Superb product exposure and display

- Sustainability and repeatability on long-term basis

Challenges of Glass Packaging:

- Great weight adding to the cost of transportation

- Multiple delicate parts which must be handled and padded carefully

- Increased cost of production and raw material The cost of producing and raw materials were an increased cost.

- the restriction of flexibility in design as compared to other materials

- Safety issues of the breakage

Metal: The Protective Barrier

Metallic containers, which are mainly aluminum and steel, are as well very protective and barrier type. They are especially useful in intermediate bulk containers for products that have long shelf life and those that need to be flanked against the environmental factors.

Benefits of Metal Packaging:

- Excellent barrier strength to light, oxygen and moisture

- Great structural strength and durability

- Unlimited recycling with no compromise of quality

- Tampering functions composing features

- Prolonged-storekeepers life preservation

- Tolerance to the extreme temperatures

Challenges of Metal Packaging:

- Increased cost of material and production Higher material and production cost

- Weight that has major implications on shipping costs

- Poor design capability of complicated shapes

- Possibility of being dented and cosmetics damage

- Environmental issues on corrosion in specific environments

Paper-Based Materials

Kraft Paper: The Natural Solution

Kraft is one of the most eco-friendly packages that can be offered, especially when combined with paper foil laminate . Kraft is one of the most eco-friendly packages that can be offered, especially when combined with baking paper.

Benefits of Kraft Paper:

- 100 per cent biodegradable and compostable

- Branding Excellent printability on branding Excellent printability

- Economical production and purchase

- Natural aesthetically appeal

- May be recycled as normal paper

- Renewable resources base

Challenges of Kraft Paper:

- Low moisture resistivity; no treatments

- Blocked rather easily to tearing during stress

- Limited security of delicate objects

- Heavy product weight restrictions

- Wet loss Degradation in humid conditions

Tissue Paper: The Delicate Protector

Tissue paper is used in special packaging applications where care has to be taken; also gift packs. Its lightweight characteristics and protective effects are mild entailing suitable applications.

Benefits of Tissue Paper:

- Soft cushioning of fragile surfaces

- Cheap and easily portable

- Great package gift giving

- Recyclable and biodegradable

- Simple editability through printing and colours

- Small storage space supplies

Challenges of Tissue Paper:

- Poor defensive powers

- Moisture sensitivity

- Low barrier characteristics

- Delicate delicacy demands

- Poor onset capacities

Specialty Materials

Wood: The Traditional Choice

Wood packaging does not lose its spot in heavy and specific products. Industrial uses require high strength box variants, such as wooden crates, pallets and boxes.

Benefits of Wood Packaging:

- Outstanding capabilities of heavy goods

- Green and renewable resource

- Super cushioning values

- Reusable, repairable

- End of life (e.g. biodegradable)

- Conventional beauty value

Challenges of Wood Packaging:

- Important weight influencing costs of shipping

- Vulnerability to water destruction

- Pesticide and pollution levels

- Increased assembly labour prices

- Stiffness in design

Textile Materials: The Sustainable Alternative

The packaging materials that could be used in the textile industries are jute bags, cotton, and canvas which are eco-friendly materials to use in particular applications. Such inputs attract consumers who are environmentally-minded, as well as those that offer distinct esthetical benefits.

Benefits of Textile Materials:

- Bio-degradable and renewable

- Easy to reuse and tough

- Special esthetic value

- Permeability of some products

- Personalisable by printing and dyeing

- Artisanal associations and Traditional associations

Challenges of Textile Materials:

- Weak defense options

- Increased costs of production

- When it comes to staining and wearing it is sensitive to wear and stains.

- Performance in barrier properties is poor.

- Expert cleaning needs

Innovative and Eco-Friendly Materials

Biodegradable Plastics: The Future Solution

The most advanced technology of sustainable packaging is biodegradable plastic. This material offers the practical value of the conventional plastics and environmental responsibility.

Benefits of Biodegradable Plastics:

- The decreased impact to the environment

- Can be composted in conditions which are right

- Performance of traditional plastics comparable Other mechanical properties Designed to withstand high temperatures Able to withstand high temperatures

- Renewable source base

- Less accretion of landfills

- Favourable brand association

Challenges of Biodegradable Plastics:

- Increased costs of production

- Scarcity of availability and scalability

- Particular requirements to disposal Specifications Specifications de Specs

- Limitations of certain applications in respect to performance

- The mandates of consumer education

Cornstarch-Based Materials: The Plant-Powered Option

Packaging materials made of cornstarch are renewable substitutes to plastic made of petroleum. These materials equate to the use of agricultural wastes to create livable products in packaging such as food grade trays .

Benefits of Cornstarch Materials:

- Agricultural source of renewable form

- Bio-degradable and compostable

- Low carbon footprint

- Functionalty comparable with the conventional plastics

- Agricultural subsidies

- Good environmental messages

Challenges of Cornstarch Materials:

- Short supply and increased prices

- Extremes of operation performance restriction

- engaged in special processing needs

- Possible food rivalry Potential rivalry against food

- Problems of consumer consciousness

Industry Applications of Packaging Materials

Food Industry Applications

The food industry requires packaging materials which guarantee safety of the product, shelf life and quality of products all through the supply lines. Various food product packages have particular properties of packaging materials, including plastic pallets, needed to keep freshness intact and avoid any contamination besides meeting the regulatory directives.

Fresh Produce Packaging

Packaging of fresh produce will involve tertiary packaging material that will provide adequate ventilation but immunity against physical damage. Mesh materials, breathable paper bags, and perforated plastic films permit the interchange of gases through the delivery of a product and its integrity.

Processed Food Packaging

Packaging processed food needs materials that are barriers to moisture, oxygen and light. The appropriate protection allows long shelf life by use of multi-layer films, aluminum foils laminates, and special formulations of plastic.

Beverage Packaging

Liquid drinks require package types that won t require contamination, be carbonated and retain flavor. Depending on the type of beverage we are facing its own characteristics, the right sized packaging like glass bottle, the aluminum can, and the special plastic bottle have their own advantages.

Frozen Food Packaging

The packaging involved in frozen foods has to be materials to uphold their integrity at low temperatures without allowing freezer burn and moisture. Frozen goods are best preserved in specific wooden containers and intermediate bulk containers made from layered paperboards.

Electronics Industry Applications

Packaging electronics requires materials which offer electrostatic discharge protection, physical shock cushioning, moisture and contaminant barriers.

Component Packaging

Electronic parts need special packaging material that does not damage the parts through static electricity yet it must be easy to handle and identify. This is best prepared on conductive foam, on antistatic films and on specific trays.

Consumer Electronics Packaging

Packaging of consumer electronics should be done to protect and present an attractive look. Plastic trays formed into shape and cushioning fillers, as well as good-looking printing materials, make good packages.

Industrial Electronics Packaging

The electronics used in industries must be well packaged with durable materials that will also resist rough handling conditions during shipping and withstand protection measures over a long period of time. The products are preserved with the use of heavy-duty corrugated boxes, foam inserts and barrier films.

Pharmaceutical Industry Applications

Pharmaceutical packaging materials should satisfy stiff regulations and at the same time maintain product security, effectiveness and tamper evidences.

Tablet and Capsule Packaging

The designing of packaging of tablets and capsules needs cases that are effective to preserve against dampness, light, and contamination with child-prohibition characteristics. There are different solutions in blister packs, bottle systems, and strip packaging.

Liquid Medication Packaging

Liquid drugs need materials of packaging that avoid contamination of the drugs, correct dosage, stability of the product. Vials made of glass and bottles made of plastic with a special closure system offer the best protection.

Injectable Drug Packaging

The purity of materials used in packaging and sterility is required to a greatest extent in injectable drugs. The borosilicate glass, special rubber stoppers and sterile packaging systems make the product safe.

Cosmetic Industry Applications

Packaging material of cosmetics should have both the ability to protect the cosmetic products and aesthetics to have an attractive packaging solution.

Skincare Product Packaging

The skincare products will need packaging materials that can withstand light, air and contamination and help in keeping the products stable. Best protection is provided by the airless pumps, light-resistant containers and barrier materials.

Color Cosmetics Packaging

Packaging of color cosmetics more than any other cosmetic brings the aesthetics to the forefront besides giving the product the necessary protection. The small size systems, a special applicator and ornamental materials provide appealing formats of packaging.

Fragrance Packaging

Packaging demands products that avoid evaporation, shield light and produce quality presentation in fragrances. Bottles made of glass, special closures, outer packaging, and quality bakery paper guarantee the preservation of the products.

Selecting the Right Packaging Material

Product Characteristics Assessment

Packaging materials, including secondary packaging, need to be chosen carefully and a good assessment of the product characteristics should start this process. The size of a product, its weight, strength and special requirements all come in to play in the choice of material.

Physical Properties Evaluation

Structural demands of packaging materials are determined by physical comprising such varying data as dimensions, weight, and density. Heavier items must be manufactured using stronger materials whereas fragile ones will need to be cushioned and padded.

Chemical Compatibility Assessment

Compounding chemicals to ensure compatibility between products and packaging material predetermines lack of contamination, deterioration, and quality defects. Knowledge on how the materials interact guarantees the safety and integrity of the product.

Environmental Sensitivity Analysis

Barrier property requirements depend on environmental sensitivity which comprises of moisture, temperature and light exposure. There are sensitive products that would need special materials with suitable protective properties.

Shipping and Distribution Requirements

The means of shipping and distribution have great influence on the material of packaging. The knowledge about transportation, handling and storing methods provides adequate material selection.

Transportation Method Considerations

Various means of transportation has their own requirements and challenges. Air freight will need to be of light materials, whereas characteristics of ocean shipping need to have moisture protection and also have stability.

Handling and Storage Conditions

Such things as handling, storage conditions such as temperatures variation, humidity levels, and stacking needs have an impact on the selection of materials. Strong materials, especially those with multiple layers, will provide protection of the product on the supply chain.

Distribution Network Analysis

The nature of the distribution networks in terms of warehouse conditions, means of handling and delivery is influential on packaging material needs. Knowing of these factors provides that the best material choice is made.

Cost Considerations and Budget Constraints

The consideration of cost balances between material performance and the financial aspect. Knowledge on the total cost of ownership over and above material costs, processing costs, and possible savings will influence the decision making.

Material Cost Analysis

The cost of materials differs mainly in terms of quantity requirement, quality and type. The costs are thoroughly evaluated comprising of purchase prices, production costs, and wastages.

Processing and Handling Costs

The costs of processing and handling comprise the conversion costs, the print cost and assembly costs. Knowledge about the costs is useful in achieving more productive material selection and processing process.

Total Cost of Ownership Evaluation

Total cost of ownership covers material costs, processing costs, shipping costs and the savings that may be made through minimising damages or returns. Thorough examination guarantees best possible selection of the material.

Environmental Impact Assessment

Environmental impact assessment considers the amount of environmental footprint of packaging materials during its life cycle. The concept of the implications of environmental awareness informs the selection of sustainable materials.

Lifecycle Analysis

A lifecycle analysis studies the effects that impact on the environment at the point of raw materials up to disposal. This is complex measurement that takes into consideration carbon footprint, use of resources as well as waste.

Recyclability and Disposal Options

Consumers and impact on the environment are influenced by part of its recyclability and ways it can be discarded. The selection of the material is determined by the knowledge about recycling possibilities and disposing in the area.

Sustainability Certifications

Sustainability certifications make third-party confirmation to give evidence to the environmental claims. Established certifications aid in passing information about environment to consumers and other people.

Current Trends in Packaging Materials

Sustainability and Environmental Consciousness

The packaging sector is also taking a major turn towards being eco-friendly and environmentally-promoting. It is caused by the demands of customers and regulatory requirements as well as corporate responsibility campaigns.

Circular Economy Principles

The principles of circular economics focus on recycling materials, using them again, and less waste. Circular packaging materials are useful in managing resources sustainably and aim at protecting the environment.

Bio-Based Material Development

The development of bio-based materials emphasizes and highlights on renewable materials and biodegradable products. These substitute materials provide a lower environmental friendship but ensure that the functional performances are up to standard.

Waste Reduction Strategies

The options of reducing the wastes are source reduction, optimization of the design and better recycling. Such strategies are eco-friendly and do not affect packaging functionality.

Smart and Intelligent Packaging

Smart and intelligent packaging smart and intelligent packaging combine technology with functionality, information, and user experience. These additions are the way of packaging in the future.

Sensor Integration

The requirement of monitoring of product conditions such as temperature, humidity and freshness is facilitated through the use of sensor integration that can perform this task in real time. These technologies enhance quality and product safety.

Interactive Features

Interactive functions such as the use of QR codes, NFC tags and augmented reality create effective consumer experiences. Such technologies stimulate brand communication and product information.

Tracking and Authentication

There is tracking and authentication technology that warrants against counterfeiting as well as the affinity of supply chain. Such characteristics enhance product safety and consumer trust fulfillment.

Customization and Personalization

The phenomena of customization and personalization allow the brands to produce the unique packaging experience that appeals to individual consumers and target markets.

Digital Printing Advancement

The level of perfection in digital printing allows it to cost-efficient customization and small-quantities printing. The technologies promote customized packaging and quick market response.

Mass Customization

Mass customization involves efficient production of goods, which are personalized. This method can help brands to provide distinct packages, and at the same time, it is cost-effective.

Variable Data Printing

The possibility of packaging materials customization per individual is possible in variable data printing. This technology enables individual marketing and better engagement of the consumers.

Quality Control and Testing of Packaging Materials

Testing Standards and Protocols

Quality control, and testing allow seeing whether packaging materials perform satisfactorily and whether they comply with regulatory standards. Extensive tests procedures prove the material properties and performance features.

Mechanical Property Testing

Mechanical property testing involves testing strength, durability and performance under stress. Through these tests, packaging materials offer sufficient protection along the supply chain.

Barrier Property Testing

Barrier property testing is the test of resistance to moisture, oxygen, etc. Such tests will ascertain that packaging materials are offering proper protection to certain products.

Compatibility Testing

Interactions of packaging materials and product are tested through compatibility testing. Such tests avoid contamination, deterioration and quality problems.

Regulatory Compliance

Regulatory compliance makes use of packaging materials to be safe, labeled and environmentally satisfactory. The goals of knowing regulatory landscape inform the choice of materials and test procedures.

Food Contact Regulations

Packaging material of food products is subjected to foods contact regulations. These food contact regulations guarantee food contact material safety and exclude contamination.

Pharmaceutical Packaging Requirements

The pharmaceutical packaging needs are one of the strictest in the market. Such regulations make materials fit safety, efficacy, and quality requirements.

Environmental Regulations

Packaging materials are regulated in terms of the packaging material composition, the labeling, and disposal. The regulations facilitate sustainability and the environment.

Performance Validation

Performance verification ensures the packaging materials are fit as per the requirements both under ideal and actual cases. The breadth of the validation guarantees the reliability of the performance in the supply chain.

Accelerated Testing

Accelerated testing is a short duration of exposure to a higher degree of exposure. The tests give quick evaluation of performance and degradation properties of materials.

Field Testing

Field testing assesses the ability of packaging materials in operating condition. The tests confirm the findings in the laboratory and test any possible problems in implementation prior to it ever being rolled out.

Continuous Monitoring

Monitoring on-going looks at the performance of the packaging materials over time. This strategy points at the trends, problems, and improvement possibilities.

Future Developments in Packaging Materials

Emerging Technologies

Advancing technologies are redefining the packaging materials environment as they provide new opportunities on performance, sustainability and functional capabilities.

Nanotechnology Applications

Nanotechnology Applications improve the property of packaging materials such as barrier performance, shelf life of the food item, and antimicrobial properties. The technologies allow high performance in conventional materials.

Biodegradable Polymer Development

The development of biodegradable polymers is aimed at creating substances that are degraded in a natural way and at the same time able to retain performance properties. These are the materials, including wet strength paper, which respond to environmental issues as well as fulfill functional needs.

Advanced Coating Technologies

Modern processes enhance the performance of materials without altering the base materials characteristics. The technologies can support increased functionality at minimal costs.

Market Predictions

Market forecasts show that there will be further advancement in sustainable packaging materials, including packing peanuts telligent packaging, and personalized capabilities. These are the trends which will define the development and adoption of materials in future.

Sustainability Growth

The growth of sustainability would stimulate further advancement of environment-friendly packaging materials. This tendency can be explained by the needs of the consumer base and the regulations that concern sustainability.

Technology Integration

Integration of technology will produce new abilities of packaging materials such as sensing, communication, interaction functionality. The technologies will make systems more useful and easier to use.

Customization Expansion

The continued growth of customization will allow packaging to become more customized. The trend symbolizes the demand of consumers to unique and entertaining packages.

Innovation Opportunities

Potential fields of innovation are in the areas of developing materials, technologies of processing materials and application techniques. Such possibilities will promote further development of packaging materials.

Material Science Advances

The improvements in material science will make available ‘newer and better materials with new properties and functions in terms of packaging. The developments will enhance increasing possibilities of applications and performance.

Processing Technology Improvements

The enhancement of the processing technology will grant an opportunity to produce efficiently and improve the material properties. These developments will lower the expenses and increase the quality.

Application Method Innovation

Innovation of application method will allow the new usage to make use to packaging materials. The emerging processes will increase the application potentials and enhance user experience.

Best Practices for Packaging Material Selection

Decision-Making Framework

An organized decision-making model guarantees optimal selection of the packaging materials basing on an in-depth analysis of the requirements, constraints, and opportunities.

Requirements Analysis

Requirements analysis helps to determine the most important material properties and performance features. The given process makes sure that the chosen materials can satisfy all requirements.

Constraint Evaluation

The constraints evaluation may determine restrictions such as expenses, availability and regulatory standards. Knowledge of limitations helps make feasible material selection choices.

Opportunity Assessment

Identification of opportunities involves noting of possible benefits and advantages of various material possibilities. This will enable optimum utilisation of material selection decision.

Implementation Strategies

The implementation strategies guarantee effective adaption of the chosen packaging products. There is thorough planning that helps to solve the possible difficulties and create a good shift.

Pilot Testing

The pilot testing is use to test material performance before implementation. This is a strategy that grades the problems and vindicates performance prior to the making of big commitments.

Supply Chain Integration

Integration in supply chain implies that materials chosen are compatible in current operations. The process corresponds to the logistic, handling and processing needs.

Training and Education

Training and education helps the personnel to have an idea of new materials and what is needed. In this manner, it avoids problems and allows the best performance.

Continuous Improvement

With the aid of continuous improvement processes, packaging materials are maintained in a manner that head to the changing needs and opportunities. Goodness is ensured through the normal assessment and improvement.

Performance Monitoring

Performance monitoring monitors the effectiveness of materials with time. This procedure distinguishes trends, problems and areas of enhancement.

Feedback Integration

Feedback integration entails considering the opinions of the customers, part makers and stakeholders. This methodology will help attain materials addressing all possible needs and expectations.

Innovation Adoption

Adaptation of innovation makes sure that organizations enjoy new material developments and technologies. The process sustains competitive benefit and excellent performance.

Conclusion

The world of the packaging materials is huge and the choice is immense, yet each available packaging material is distinctive with its peculiarities and advantages and disadvantages. Whether it is a conventional material such as industrial packaging like cardboard, plastic, or wooden pallets, or the new biological packaging, the primary packaging material used also has a major influence on the protection of the product, on its brand perception, as well as on the environmental responsibility. Learning about the strengths, areas of use, and limitations of various types of packaging materials would allow making better choices by balancing performance, prices, and sustainability needs.

Sustainable, smart, and customized packaging solutions are the way forward considering the emerging consumer trends and other requirements of keeping the environment clean. With further development of technology and environmental awareness, the material that is used in packaging will keep on changing and the innovation and chances of improvement keep on increasing. The good performance in selecting materials used in packaging entails an overall assessment of requirements and constraints as well as opportunities alongside the ongoing assessing and enhancing programme.

With the knowledge of the available packaging materials and trends, companies in an informed position to make business decisions that will safeguard the products, improve brand popularity, and ensure focus on environmental sustainability. The returns on doing their homework on selecting and adopting the right packaging material are reflected in the pleasant customer experience, image and eventual profitability of the business.