Effective OEM watch packaging requires a strict process regulation, including concept design to mass production- not individual design choices or last-minute corrections. During my time as a project manager of packaging of higher end brands, I have witnessed far too many teams abandon packaging to the last minute only to have to re-do all their work after the cost of production realities collided with initial sketches. This is simple because fact is; most risks in the manufacturing processes of custom watch packaging are entrenched at early stages. Design in itself does not often pass in touch with tooling, materials, and scale.

Success in the OEM watch packaging projects is achieved when the initial decisions on the design, engineering and manufacturing are harmonized.

Why OEM Process Discipline Matters in Watch Packaging

The watch packaging projects tend to be exceptionally insensitive to misalignment since each factor bending the movements of delicate items, a perfect fit of inserts, a high-grade unboxing experience, must have a by-scale spot function.

Unorderly indiscipline will multiply minor initial imperfections: a plus or minus tolerance in insert foam will cause watches to move in transit; a ambitious foil pattern will exceed machine capacity and result in trade-offs; material selections will be insensitive to humidity in certain high potential markets and result in warping during shipment. These are not isolated occurrences: these are results when teams do not go through intensive planning.

Good OEM process control minimizes variability by compelling decisions upstream. It reduces rework (which can increase expenses by 20-40 per cent on bad projects), flatten the output curve between batches and offers the uniform premium experience watch brands that it promises its clients. Concisely, discipline does not mean bureaucracy, it is high-value low-volume luxury run risk management.

Concept Design and Requirement Definition

Origins of every successful OEM watch packing procedure lie in terms of actualizing the obscure brand desires into as actualized and practical specifications before someone scribbles a line.

The step begins with the profound deliberation: What is the required protection of the watch (number of drops, vibration in the course of delivery)? Which is more critical presentation or stackability when it comes to retail/e-commerce? What are achievable unit costs at operating volumes? Our definition of these is early because they determine all downstream: rigid vs. folding construction, the kind of insert (EVA foam, molded pulp, or paperboard), finishes that survive handling on the surface.

Brands rushing here very frequently find out too late that what they have thought of as minimalist luxury still needs complicated structures to add to either tooling costs or lead times. Early targets deter such drift. To get a further explanation of how to strike the balance between these trade-offs, see our guide on how to choose luxury watch packaging.

Packaging Design and Brand Alignment

As soon as the requirements are established, structural design and visual design have to uphold the precise positioning of the brand that may be quiet elegance in the case of minimalist lines, bombastic heritage-clues in the case of classic collections, without causing production headaches.

Any misalignment in this case is a waste of money: a package that seems to not fit the brand fails to add to the perceived value of the watch, and extravagant details (too many layers or fancy finishes) become a choke in the assembly process. I have seen things that do not proceed after a gorgeous rendering due to the lack of consideration of the depth of the debossing in relation to die-cutting accuracy, or the interaction between spot UV and hot soft-touch lam.

The idea is that of coherence: all the tactile and visual details must reflect on the watch itself. With strong alignment, the box is a continuation of the product narrative. Explore this further in packaging design for watch brands.

To have a functional system that ensures all these aspects are aligned, many brands turn to integrated OEM and ODM watch packaging services that handle the full workflow under one roof.

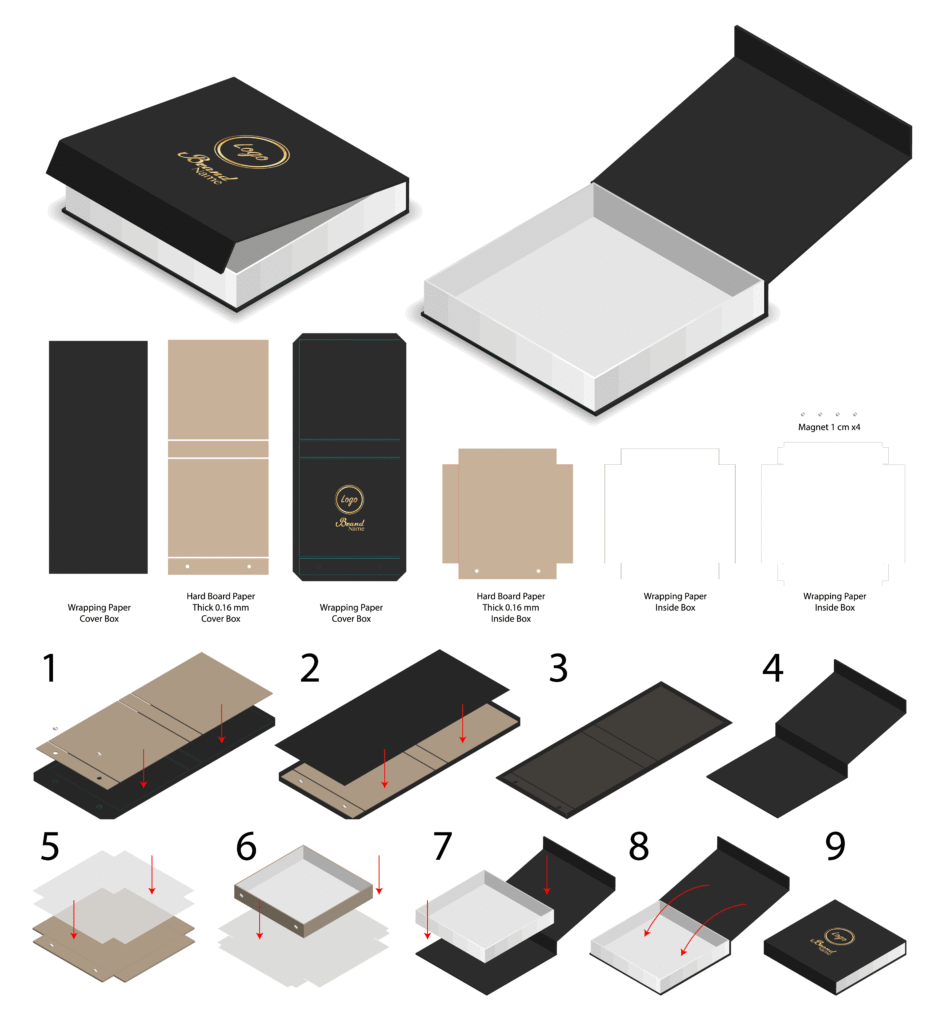

Engineering, Prototyping, and Sample Validation

The approved designs are transformed into reality that can be built by structural engineering, calculating tolerances, insert compression, magnetic closing strength, drawer slide smoothness, and so forth; and the durability of the box is considered in the reality of the logistics.

The concept of prototyping is a must: perfect computer-aided design files will show some problems as soon as actual samples are created. Some typical findings are the presence of foam inserts which are crushed with stacking weight, hinges that bind when the material is of uneven thickness, or foil that flakes when loaded onto the assembly line. Such failures are not failures, but rather the anticipated check points to enable some adjustments to be made prior to cutting steel dies.

The best method of increasing the costs in the future is to skip or hurry samples. Validation in this case assures manufacturability and guard against the shock in watch packaging mass production.

All these pitfalls are exactly what many brands fall into—see our breakdown of issues brands face with custom watch boxes.

Manufacturing Planning, MOQ, and Lead Time Control

Lay planning in terms of production reality: lead time in material sourcing, fabrication of tooling (dies, molds used to form inserts), production plate setup, balancing of an assembly line.

MOQ and lead time should be locked at an early stage since they are directly related to structure and finishes. Simple foil folding cartons are more readily scaled as a magnetic rigid box of various foil color might need higher minimums due to the complexities of set-ups. Scheduling also depends on material selections (e.g. FSC certified card stock and specialty papers) where exotic selections may be 8-12 week lead times.

Planning helps avoid last minute panicking which increases the cost or launches. To gain a better understanding of these variables look at review understanding MOQ and lead time for watch packaging.

Mass Production, Quality Control, and Consistency

Only when all signs on pre-production samples and pilot runs are given, mass production is started. The transition is a test of process controls being good at volume: consistency of printing colors on thousands of sheets, placement of prints on semi-automated lines is accurate, end assembly is flawless.

Quality is not checked in; but rather constructed in multi-stage inspections: raw material entering inspection, in process (print registration, foil adhesion) sample inspection, and final strict audit (100) visual/functional check. The printing, finishing, and assembly process is in-house, so there is limited deviation, any drift is detected and corrected before full runs go through.

The harmless consistency is inevitable: all the boxes are similar to the approved sample, and no risk to brand reputation exists in the domain of global distribution.

Conclusion — OEM Success Is Built Through Process Alignment

OEM watch packaging projects are successful as long as all steps such as concept design through mass production are accorded a controlled process. Orderliness, economy and delivery punctuality are products of a rigorous arrangement and not emergency solutions. When teams consider the workflow as a system of operations and not a chain of creative jumps, the risks are reduced significantly and the results can be reproduced.

In reality, that science isolates those brands whose launching works well, from those that combat the fire of production. The more it is aligned earlier the better place to be.