Imagine the following: you are sitting at your computer as you are completing the design of the new product catalog at your company and everything looks fine on the computer screen. However now comes the very critical choice that will or will not make your first impression with customers, is it better to use a matte lamination finish or gloss lamination finish? This single decision will not only determine the appearance and feel of your materials, but it will also determine their longevity, price and the impression they give about your brand.

This full-fledged guide you will find out the perfect time to use matte or gloss lamination, the effect of each finish on the functionality and perception of your project, and real life examples of how not to become costly mistakes. The reason is that the truth is that matte and gloss finish is much more than just an aesthetic decision; it affects the reproduction of colors and durability, as well as the experience of the user and the cost of production.

What Is Lamination?

Lamination is a process by which a protective coating, a thin plastic layer, is bonded onto printed materials, using either heat, pressure, or glue. This clear coating attaches itself to the surface of the paper or cardboard, forming a protective layer that improves the beauty and performance of the paper.

The main purposes of laminating are to prevent moisture, dirt, and wear; to increase the durability of objects that have to be handled often; to make it more attractive by saturating colors; and to get the high-quality touch that adds value to products. Lamination can be used to turn simple printed products into professional, durable products, whether it is business card production, packaging, or marketing materials.

Types of common laminations are thermal lamination (which involves adhesives activated by heat), cold lamination (which involves adhesives activated by pressure), and liquid lamination (which involves the coating being applied). Both techniques may be used to create a matte or glossy finish, but commercial usage of thermal lamination is the most popular.

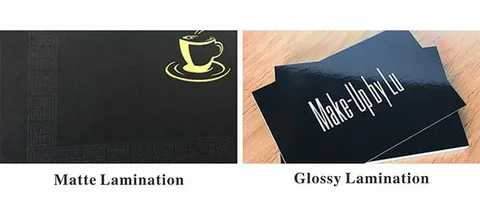

What Is Matte Lamination?

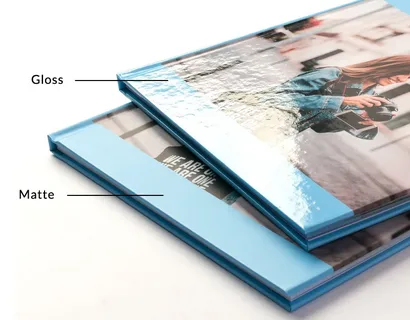

Matte lamination produces a non-reflective surface which is smooth and velvety and that takes a sophisticated feeling to the touch. Instead of reflecting light, this finish diffuses the light, leading to less glare and a subtle elegance that breathes out loud.

Advantages of Matte Lamination:

- Eradicates glare and reflections and enhances readability in different lighting conditions.

- Offers high-end, quality feel that is classy and sophisticated.

- Fingerprints and smudges are less resistant to gloss finish compared to resists.

- Has good writability – pens and markers are good on the surface.

- Provides a high-tech background that does not distract contents.

- Lessens eye pressure when reading texts with a lot of text.

Matte lamination is a highly preferred product in packaging luxurious packages, coffee table books, high-end business cards, wine labels, and corporate brochures, where the sophistication and legibility of the product is of high value. The finish especially complements minimalist designs, black and white photographs, as well as brands that would like to be considered premium or sophisticated.

Potential limitations include:

- Colors can be a little dulled compared to gloss finishes.

- More prone to noticeable scuffs and scratches on dark surfaces.

- It is always a little expensive compared to gloss lamination.

- May does not offer the same pop with bright and colorful designs.

What Is Gloss Lamination?

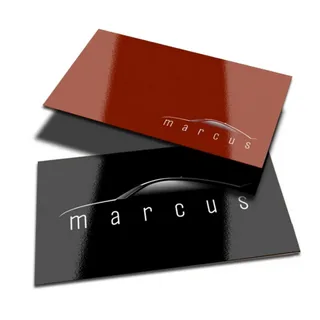

The gloss lamination creates a very reflective and mirror-like surface, which enhances colors and creates a dramatic visual effect. This finish is a magnifying glass to your design elements that makes colors brighter, images clearer, and the general look more captivating.

Advantages of Gloss Lamination:

- Dramatically enhances color saturation and vibrancy

- It majestically increases the intensity of colors and their brightness.

- Makes maximum visual impact and shelf appeal.

- Wipe down and easy to clean in comparison to matte surfaces.

- Most economically efficient than matte lamination.

- Gives great protection against spills and water.

- Makes photographic images and graphics look more active and sharp.

Gloss lamination is most suitable for packaging retail products, children’s books, restaurant menus, product catalogs, and promotional flyers, as well as any other application where the main aim is to attract attention. It is very effective with photography-intensive designs, a bright color palette, and brands with younger demographics or impulse buying.

Potential drawbacks include:

- Much direct lighting may cause serious glare and thus reduce readability.

- Easily reveals fingerprints, dust, and scratches.

- Hard to bring out using ordinary pens or markers.

- It is capable of reflecting undesirable images under some viewing conditions.

- Unless used in a considered manner, May can look cheap or garish.

Side-by-Side Comparison: Matte vs Gloss

| Criteria | Matte Lamination | Gloss Lamination |

| Appearance & Visual Impact | Subtle, sophisticated, reduces glare | Bold, vibrant, eye-catching with high shine |

| Durability & Protection | Good scratch resistance, but shows scuffs on dark colors | Excellent moisture protection, visible scratches, and fingerprints |

| Print & Color Reproduction | Slightly muted colors, excellent for text readability | Enhanced color saturation makes images pop |

| Usability & Handling | Excellent writability, comfortable grip, and less slippery | Easy to clean, can be slippery, and difficult to write on |

| Cost Considerations | Typically 10-15% more expensive | More economical, standard pricing |

| Environmental Impact | Similar recyclability challenges | Same environmental considerations as matter |

When to Choose Matte Lamination

Matte lamination is the most appropriate option in a scenario where the emphasis would be on sophistication and readability rather than the eye-catching effect. Take into account the matter when your luxury product package is needed and you do not want to show off, but express the top quality. Corporate materials such as annual reports, executive presentations, and upscale business cards are better off with the professional look of matte.

Certain applications in which matte is better than glass are wine and spirits packages, cosmetics aimed at older customers, building portfolios, art gallery information sheets, and any product that is going to be presented in bright retail environments where glare would be an issue.

Design tips for matte lamination:

- Use very rich and deep colors that still have an effect, even a little bit dulled.

- Maximum readability should be achieved using high contrast text combinations.

- Emboss or spot UV to provide gloss-free tactile interest.

- Accuracy on test colors using real matte samples before final production.

- Do not use large spots of solid dark colors where scuffs can be observed.

When to Choose Gloss Lamination

Gloss lamination is also preferred when you have as your main objective a high visual impact and color vibration. Gloss is popular in retail settings because it appeals to the shelf – candy wrappings, toy boxes, and what should be sold at the impulse. Trade show displays, promotional flyers, and point-of-sale materials are marketing materials that require the eye-catching characteristics of gloss.

Use gloss with children’s products, food packaging products (where easy cleanliness is a factor), photographic portfolios, travel brochures, and where the product must stand out in the crowd or, visually, must pop when viewed at a distance.

Design optimization for gloss:

- Apply rich, juicy colors that will be made brighter by the finish.

- Include quality photography, which has the advantage of having more contrast.

- Large blocks of text should be avoided as they may cause glare to make them hard to read.

- Take into account the watching conditions and the lighting.

- Arrange to have items that are handled frequently visible in fingerprints.

Hybrid & Special Finishes

The matte or gloss is not always a dichotomy. Spot gloss finishes give you an opportunity to use both finishes on the same piece so that you can use gloss selectively to emphasize logos, pictures, or important details and leave the parts that need to be read as matte. This produces advanced contrast and gives emphasis to certain details.

Other finishes are soft-touch lamination (velvet-like feel), UV spot finishes (gloss raised areas), silk lamination (between matte and gloss), and textured finishes which give it a touch of interest. Both options have a certain design purpose and may offer special solutions in situations when your needs cannot be perfectly satisfied with the standard matte or gloss.

Cost, Production & Practical Considerations

The cost to manufacture would prefer gloss lamination, which is operated at a 10-15% lower cost than matte lamination. Nonetheless, this difference in costs is frequently insignificant in the large production batches. Both finishes usually have similar lead times, but more specialty matte films may take more time to process.

Take shipping into account – glossy surfaces can be easier to notice as scratched during shipping, whereas matte finishes conceal small scratches. Minimum order quantities are usually fixed irrespective of the type of finishes used; however, premium matte films are likely to have higher MOQs supplied by the suppliers.

Consumer perception analysis has always reported matte finishes to be linked with high positioning and more perceived value, whereas gloss finishing is linked to accessibility and instant appeal. This is a psychological effect that can be used to explain the slight rise in the cost of matte, where brand positioning will help to support it.

Potential Downsides & What to Watch Out For

The typical problems with matte lamination are:

- The scuff marks traces of dark colors after some time.

- Minor color reproduction that can be displeasing to the clients who want vividness.

- Increased prices that will not be affordable to everyone.

- There is a lack of specialty colors in matte films.

Gloss lamination challenges include:

- Light blinding text readability.

- Fingerprints and dust impressions are obvious on objects touched.

- Scratches are becoming super visible on traffic pieces.

- Risks of coming off as inexpensive when used on low-quality designs.

Mitigation strategies consist of ordering physical samples before production, analyzing your target audience on how they will handle your product, thinking of your product’s most likely environment of viewing it, and then picking a finish depending on the main purpose of its use, and not because of personal choice.

How to Decide What’s Best for Your Project

Begin with the definition of your ultimate goal: Do you need to be noticed most or need to be readable long-term? Do you want to position your product in luxury or mass? Will there be regular handling of the completed product, or is it going to be displayed?

Think about your audience demographics and likes. The youthful demographics tend to select gloss due to its power and activity, whereas the more mature patron may be attracted to the elegance of matte. Consider use conditions – Do objects need to be seen in bright light where glare is a problem, or in dark conditions where color liveliness is essential?

Decision framework:

- To be positioned as luxurious and reading the text often: Select matte.

- To look as bright as possible and spend less money: Select gloss.

- In case of exclusive differentiation and specific brand demands: Design hybrid solutions.

- In case of uncertainty: Order samples of your actual content of both finishes.

Conclusion

Whether to use matte or gloss lamination will ultimately be a matter of trade-offs between aesthetics, functionality, and cost. Matte lamination has advanced sophistication, better readability, and premium positioning ata slightly higher price. In contrast, gloss lamination has maximum visual impact, better durability, and is cost-effective with few handling and glare trade-offs. One is not necessarily better than the other would be successful, as in matching the finish to your unique project objectives, target market, and the environment in which the work will be used. Physical samples taken on your actual designs and colors will help you to know the difference between what is on the screen and reality before you make your final decision.

Frequently Asked Questions

Q: Is gloss lamination more durable than matte? A: Both offer similar protective qualities, but gloss provides better moisture resistance while matte offers superior scratch resistance on light-colored materials.

Q: Does matte lamination show fingerprints? A: No, matte lamination resists fingerprints and smudges much better than gloss finishes due to its non-reflective surface texture.

Q: What’s the typical cost difference between matte and gloss lamination? A: Matte lamination typically costs 10-15% more than gloss, though this difference decreases with larger production volumes.

Q: Can you write on laminated surfaces? A: Matte lamination accepts most pens and markers well, while gloss lamination requires special markers or may not accept writing at all.

Q: Which finish is better for outdoor applications? A: Both resist weather equally well, but matte reduces sun glare while gloss may become difficult to read in bright outdoor lighting.

Q: How do I choose between matte and gloss for product packaging? A: Consider your brand positioning (matte for premium, gloss for mass appeal), target demographic, retail environment lighting, and whether customers will handle the package frequently.