Introduction

Imagine that: after picking out the most appropriate present, you have taken the time to wrap it very neatly, and wait excitedly to send it to a friend in a different state. A couple of days afterward, you get a sad phone call- the package was crushed, the contents are destroyed, and you were trying to be so thoughtful but were left frustrated in the end. This is what happens thousands of times every day, but does it have to happen to you?

Packing is not merely a question of getting things where they belong; it is also a question of securing your investment, satisfying customers, and preserving your reputation. You might be a small business and be shipping its products to consumers, or you might be an online store owner and be selling inventory, or you might be neither of the two but just want to send packages easily; then getting the art of shipping is something that may save you money, time, and headaches.

You can also find out the professional packing methods, get to know what material you should use on various occasions, and get to know the missteps that are usually made by even seasoned shippers. At its end, you will know how to pack like a true expert and how to make sure that your goods will arrive every time.

Choosing the Right Box

Successful shipping begins with the choice of a container. Size is important than it seems, a large box is a waste of space, and it increases transportation expenses and possibilities of items moving and even breaking during delivery. On the other hand, a box that is too small applies a lot of pressure on seams and corners, which results in structural failure.

The corrugated cardboard is the ultimate material to use when it comes to shipping requirements. Single-wall is effective in the case of lightweight products below 20 pounds, whereas the corrugated structure is better suited in the case of relatively heavier or more valuable goods. Fluting of the layers of cardboard serves as a shock absorber, and the forces of impact are dispersed throughout the surface of the box.

In the case of special goods, purpose-built containers are a good option. Boxes with inbuilt dividers are effective in safeguarding a variety of delicate objects since flat-pack boxes are used when there are several artworks or documents that need to be transported without being damaged by contact. Molded insert wine boxes, electronics packaging with custom foam cutouts, and tube containers of posters all have certain protective requirements that generic boxes are incapable of meeting.

Prepping Your Item

This preparation process begins long before anything starts to get in touch with your item in terms of packing. Clean down the surfaces- dust, liquid or dirt can leave a stain or cause damage during transportation. Tape the bits that are loose or extract batteries that are likely to leak on the moving objects, which may be electronics or mechanical machines.

A protective wrapping is the initial protective line. Bubble wrap provides better protection on sensitive items, yet, the use of bubble wrap with bubbles touching the surface is not supposed to leave an impression. They have delicate finishes so place tissue paper or soft cloth in between as protective layer then wrap in a bubble wrap. Foam padding works particularly well with objects that are sharp-edged or irregular in their shape and that would pierce the traditional wrapping material.

Awareness should be taken with delicate things. Secure them individually by wrapping them before adding dividers or additional padding to prevent contact between two or more fragile items in one container. Always consider the outer box as protection, but alway consider that it will be dropped, and pack it.

Packing Techniques

The professional packers are systematic about their layering, which is protective to the maximum. Begin with a lot of cushioning material at the bottom of the box–three or four inches of material at least, where delicate articles are to be packed. The place of your wrapped item in the box should be at the center with equal space on all sides.

The purpose of void fill goes beyond just the purpose of filling space. Paper peanuts, or air pillows, cover crumpled newspaper, and this movement will not occur during transit, and hence no damage. Put things in one by one, making sure the items do not move when you shake the sealed box.

Protection and efficiency are also important when it comes to orientation. Heavy objects should be at the very bottom, the weight should be evenly distributed, and the delicate elements should be arranged in such a way that they are not likely to be hit. Use cardboard dividers to form individual compartments when dealing with several items so that the contact will not cause any damage.

Sealing and Labeling

Good sealing can make the difference between a disaster and a safe arrival. Use a good shipping quality packing tape, or none of the duct tape, no type of masking tape, or any household tape that can be strained. The H-tape is the safest: The tape on the center seam and the corners where the box flaps meet.

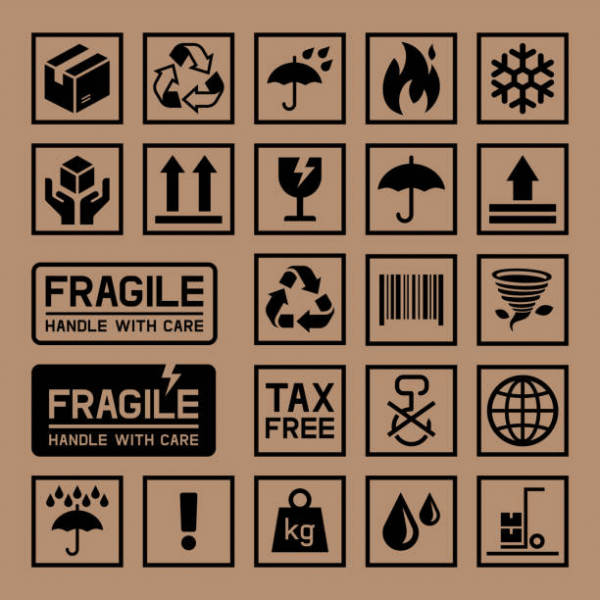

It will be properly labeled and delivered. Handwrite in waterproof handwriting and include the name of the recipients and sender, address. When there is a need, add the handling instructions: Fragile, This Side up, or do not stack, but keep them spare-overworking will overwork them.

Consider the environmental aspects of the labeling that you make. Addresses should be written with a weatherproof label, or clear tape should be placed over addresses to prevent smudges. Give the contact numbers of the two parties in the event of any delivery issues that may occur.

Special Considerations by Item Type

Electronics should be given special care because they are sensitive to the effects of impact, moisture, and static. Wrap with anti-static bubble wrap or bag, withdraw batteries, and provide a silica gel packet against moisture. Unless it is damaged, the original packaging is the best.

Paper materials and books appear to be durable but can easily be damaged at the edges or become wet. Put them in plastic bags to preserve the moisture, and do not use padded envelopes; but use rigid mailers or boxes to secure valuable objects. Position books with the spine resting low to avoid the opening of pages when under pressure.

Compression can be used in clothing and textiles to save on shipping costs; however, compression should not be done to the extent of producing permanent creases. Bags that are vacuum sealed would suit large garments such as winter coats, whereas fragile garments should be sealed in acid-free tissue paper to avoid coloring.

Bending and corner damage a problems unique to artwork and flat objects. Use rigid mailers with Do not bend written on them, or place the item in a sandwich between cardboard pieces a little bigger in size. Corner protectors help to avoid damage to frames or taut canvases.

Buying Supplies & Cost Savings

Mass purchasing also saves a significant amount of money on unit prices of regular shippers. Most of them are processed in standard box sizes of 12x12x6 or 16x12x8 inches. However, it is not always possible to buy excessive numbers of specialized sizes that can be stored away.

Green products are becoming cost-effective, besides being sustainable. Recycled corrugated is equally efficient as virgin materials at reduced cost, and most of the suppliers offer discounts when the used boxes are returned in good condition. Substitutes for petroleum-based substances that are eco-friendly are bio-packaging peanuts and recycled paper void fill.

Quality Suppliers are competitive in terms of price and do not compromise on security. The industrial packaging suppliers normally sell to individuals and offer them a more advantageous deal than what they would have had through retailing. Checking the quality ratings and the money-back policies is to be done before making large purchases, as online markets can be convenient and with a competitive price.

Storage & Maintenance of Packaging Materials

It is also known that good storage increases the lifespan of packaging materials and makes them reliable when they are them. Store boxes flat in a damp place that is not exposed to direct sunlight, which kills adhesives and destroys cardboard. When piling the heaviest boxes first, it is important to use dividers to ensure that the boxes are not squashed, and also to ensure that one uses different sizes when using them, so that when they need them, they can find them easily. Be careful of ragged edges, loose stitches, or missing seals. Always wash them thoroughly and never reuse the same containers that contained chemicals or food, among other things, that could contaminate the new item.

Frequent inspection eliminates uncomfortable surprises when the shipments are urgent. Check stored materials every month for pest damage, moisture issues, or degradation. Turnover Stock should be rotated to use the old materials initially, and inventory lists should be maintained to prevent excessive purchase of common sizes.

Common Mistakes & How to Avoid Them

One of the most frequent errors is under-packaging, which is usually encouraged by cost-saving measures. Inadequate cushioning will cause damaging motion, and inadequate box strength will cause structural collapse. Bearing in mind, replacement costs are several times more expensive than packaging.

Overpacking is an issue on its own since it results in overweight, which presses the box joints, as well as makes shipping very costly. Choose a compromise between protection and efficiency; additional padding will not always be more advantageous when it does not enable a box to close well, or when it provides an unsteady stacking.

The edge protection and corner protection should be paid particular attention to, since they are where the impact in handling is best absorbed. Place corner guards, extra padding, or special corner protection material on exposed objects. Do not believe that the general void fill will be effective to seal these high-stress areas. Failures can be prevented with shortcuts in sealing.

The integrity of boxes is compromised by the use of poor-quality tape, the use of the wrong type of tape, and application techniques. Make time to fit tapes in–to ensure that use is smooth and that there is enough overlap to prevent the development of crevices that weaken seals.

Real Life Tips & Tales

One e-commerce seller learnt the lesson of proper electronics packaging the hard way when one customer received a broken tablet when it appeared to be tightly packed in bubble wrap. The moral: the electronics need hard protection and not just cushioning, but also to the sensitive screen components. Support is provided to the sheet now with a cardboard backing, and cushioning materials are then applied over the cardboard.

When contact was with multiple items in one box, personal wrapping was not enough, and this was identified by a small business that shipped handmade ceramics. It was decided to separate the parts into separate compartments with cardboard dividers and ensure no contact between parts, regardless of whether there are some external impacts.

An artist who sells his art needs to survive through the frequent destruction of the frames till he or she has transformed the regular boxes into customized boxes with the least space. The finding: This proved to be too much space and movement, which could not be stopped through cushioning was occurring and on the other hand, boxes of the right size eliminated the problem.

Conclusion

Shipping will render the once expensive and difficult task easy, safe, and cheap. These are significant concepts of the technique to choose the correct materials, the technique to pack, the technique to seal the package, and the pitfalls to avoid, which can be used when delivering a single package or a hundred packages. Your reputation and peace of mind include good packaging, and not a cost to lose. This guide is a collection of strategies that you can start with one or two strategies and then build your skills. Make people acquainted with what you find yourself packing, and never feel embarrassed to study through what shipping should teach–they are the general masters.