Meta Description: Wondering how to get the right measurements of shipping boxes? Read this guide to get the best piece of advice on package dimensions . Find out the appropriate methods, equipment, and industry practices of shipping containers length, width and height measurement to guaranty maximum cost effective packaging and shipping cost, especially for packages .

Correct shipping box measurement is a basic skill that may save your company a lot of money, eliminate shipping problems and secure safe delivery of your products. Having an e-commerce business, warehouse, or any other occasion where one is in a need to ship an item, it is important to be acquainted with how shipping boxes are supposed to be measured in order to ensure effective logistics and understand shipping rates when you visit the post office .

Measurement of shipping box is not just a couple of rulers on the sides of a container. It has industry conventions, particular standards of measurement and real–life issues that influence everything, including shipping charges and safety of products. We have prepared an all-inclusive guide, with an example, to explain to you all the means and ways of measuring shipping boxes in a proper and effective manner.

Understanding Box Measurement Fundamentals

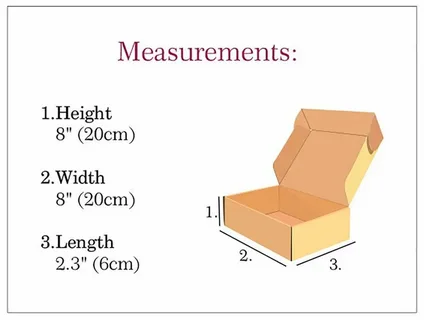

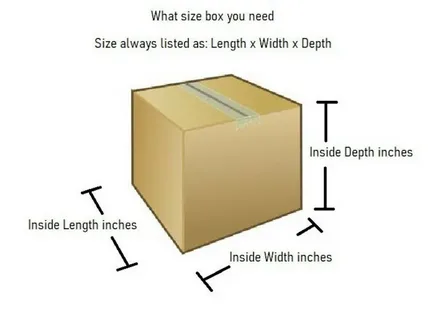

Box measurement has been standard in such a way that results in uniformity in the shipping industry. In all proceedings given Listed dimensions are always internal dimensions which implies that measurements can only be of the internal space they can accommodate your products and not the outside dimension of the box itself. This domestic measurement unit, along with girth, is important in that it defines the space, which is really available to package your products.

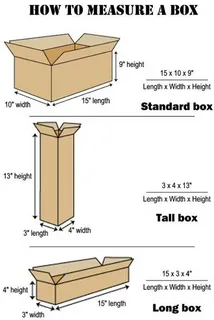

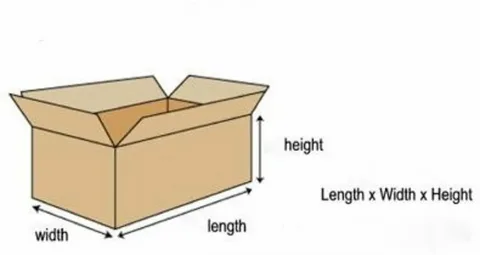

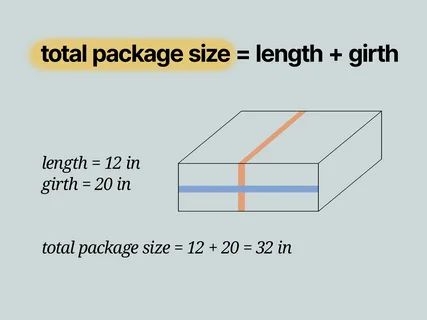

The normal order of measuring provides length followed by width and then height and this measurement always follows that sequence. Length is defined as the longest size of the box opening, width as the smaller size of the opening and height as the vertical location above the bottom of the box. The knowledge of this order, including length and girth, can avoid a situation where one mixes up when ordering boxes or expenses of shipping.

Box measurements are also caused by manufacturing tolerances. The acceptable manufacturing variance is +/- 1/8″, and thus the dimensions of your box can be slightly different than the specified ones. This is a normal variance that explains the process of manufacture of cardboard boxes, which can affect the maximum weight .

Essential Tools for Measuring Shipping Boxes

The use of the right tools is of great importance in making your box measurements accurate. Normal rulers can be used on small boxes whereas the tape measure would be more precise and more useful on bigger shipping containers. Metal tapes offer improved durability and accuracy as opposed to the fabric and plastic ones.

The digital calipers are the most accurate and reliable in making critical measurements as maybe applied in case of custom packaging or where precise dimensions are paramount to automated packaging systems. Such instruments have a scale that can be read to very small degrees; within thousandths of an inch, ensuring accurate package size .

With businesses that routinely measure boxes, it can be very cost effective to invest in a measuring station or a measuring area. A proper work place should be provided that will have good lighting, straight surface and access to measuring devices, especially with considerations for usps ground advantage . Other operations are advantaged by measure templates or jigs which accelerate the process on frequently used box sizes.

Step-by-Step Box Measurement Process

The first is to set the box on a good level surface with the opening uppermost. This orientation makes absolutely sure that you are measuring the internal dimensions right and it gives the most accurate measures for when you visit the post office . When the box is flapped, make sure that flaps are opened all the way to land on the real inside measurements.

Take the length measurements and remember to also measure width , that is place your measuring instrument on the longest internal length of the box opening. The measuring device must lie horizontally on the bottom of the box stretching between one inner wall to the other inner wall, ensuring you measure the longest side . Note this distance as the length.

The second step is the measurement of the width, so place your measurement device perpendicular to the length measurement. This ought to be lined up as the shorter of the box opening measurement, one end internal sidewall to the opposite internal sidewall. Once more, make sure that the measuring tool is in a plane contact with the box bottom to get the combined length accurately .

Lastly, take the dimension with your measurement tool by having it perpendicular to the base of the box to the edge. This dimension must be measured internally using the bottom surface to the uppermost corner of the box walls, calculating in cubic inches without any sorts of flap protrusions.

Common Measurement Mistakes to Avoid

Inaccurate measurement of a box is one of the most common mistakes that people make. In this measurement, people end up measuring the outside dimensions rather than the inside ones. These errors may result in a situation in which you have ordered the boxes that are inappropriate to your products or have made an error in the costs of transportation. The point is, whenever you talk about box dimensions, you speak about the internal area that may be used to pack things and determine postage, including girth combined.

Measurement order is the other pitfall. The lenght, width, height order should always be adhered to ensure that industry standard is followed. Ordering the wrong box sizes, or perhaps one gets confused with the inventory by mixing this order, including girth combined, can result in that.

Other mistakes in the measurement of boxed that may occur is measuring packed or bumped boxes and produce wrong measurement results. Then always measure using boxes of correct size and condition. When measuring dimensions of a box for mail, make sure it is reshaped slightly after compression to provide accurate measurements.

Industry Standards and Conventions

In the shipping business there are particular standards used in the measurement of boxes used that is uniform across the various manufacturers and suppliers. The standards, including those set by usps, aid in consistency of packaging, shipping calculations and inventory management systems.

ECT ratings or other specifications regarding strength will usually make a correlation with the size of the box, therefore proper measurements are essential in order to validate that you are using the right sized containers with correctly rated containers when storing your products. Improperly measured boxes do not have sufficient protection on what they contain, especially if the package exceeds the expected dimensions .

Additional measurements priority may need to be provided in international shipping since other countries may use other principles to measure or have certain specifications regarding the size of packages. Businesses that involve international trade should understand these differences, as they may have implications for free shipping option, leading to potential discounted shipping rates flat rate boxes.

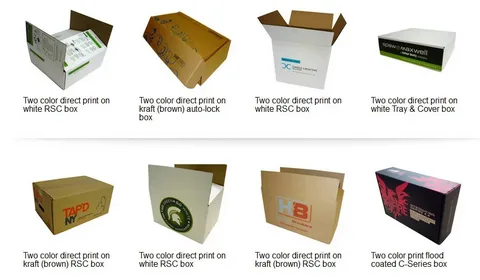

Different Types of Shipping Boxes shipping costs and Their Measurement package size Considerations

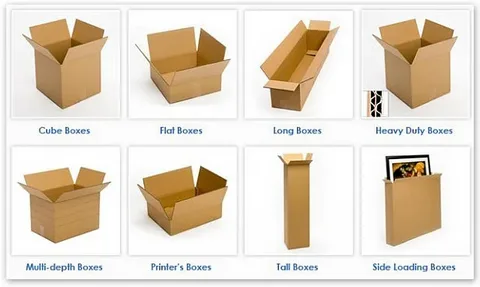

Common shipping boxes usually have regular rectangular sizes and measuring them is easy since their length, width, and height can be measured easily by using the standard method of length, width, and height. This is the most widely used type of boxes in shipping firms and typically contain walls of the same thickness shipping label.

Long boxes (having goods of long shapes such as golf clubs or art), necessitate care in measure of the length. One dimension of such boxes can many times be much longer than the others and proper measurement of the longer dimension is essential when classifying a shipment.

The height dimension is also supported by tall boxes being used such as floor lamps or tall artwork. When taking the size of these boxes, note that you are taking the overall inside height of the box as some of these might be reinforced in the bottom that tends to impact on the internal space available postal service.

Modified measurement techniques may be applicable in specialty boxes e.g., tube containers, triangular boxes or containers of any shape. Usually these boxes require more than the usual three dimensions of measurement to completely identify the inside volume of the box mailing label.

Calculating Box Volume and Dimensional Weight

Calculation of box volume helps in cost of shipping and storage quantity. The volume is determined (internal dimensions) by multiplying length 10 25 30 This estimation provides you with the cubic space that you can use to pack materials and products without incurring additional fees .

Building on box measurements, dimensional weight calculations take place to project charges that are to be incurred during shipping in the event that the volume of the package supersedes its actual weight. To determine dimensional weight, most carriers apply a dimensional weight divisor (usually 139 when domestic shipping, 166 when international shipping) and they divide package volume by it shipping faq.

Knowing how dimensional weight correlates with actual weight allows one to make the most of his/her packing decisions. In some cases, the extra protection may be needed on a smaller box, but the end result is cheaper shipping to pay since the other factors are calculated as dimensional weight of the package maximum size.

Measuring Irregularly Shaped Boxes

Behind an irregular box, determination requires varying measurement methods. In case of cylindrical containers take the height and diameter. Diameter is to be taken taking the largest internal point and height taken is internal bottom facing the top rim pay extra.

Boxes that are box-shaped with triangular or any other polygon-shaped sides should be measured on all appropriate values. In triangular boxes, the base width, depth and height should be measured. In hexagonal or octagonal boxes measure the distance between opposite sides and the height measure height.

With tapered boxes, where at the top they are wider than at the bottom, their height should also be measured, as well as the top and bottom dimensions. This will assist in packaging space determination that is effective and also correct product fit.

Digital Tools and Apps for Box Measurement package dimensions

There are different box measurement digital solutions in the sphere of modern technologies. The same augmented reality applications used by Smartphone apps can measure the dimensions of boxes, which can help streamline your checkout process. however, this may not be precise enough to be used in shipping transactions save time.

The field of warehouse management systems often contains measurement modules that have a means to determine the dimensions of boxes depending on their weight and known forms of boxes. They can be used in large-volume operations at which it would be impractical to measure manually.

3D scanning technology offers the best digital measurement system that will develop an elaborate model of the boxes and containers. Though costly, the technology is worthwhile when it comes to operations that need strict measurements in case automated packaging systems are being incorporated..

Quality Control and Measurement Verification

Quality control of box measurement involves putting in place some sort of consistency to your overall shipping activities which implies that you enable the accuracy of the procedure of measurements. Calibration of measuring instruments and metrological techniques will ensure guarding of the standards during measurements over interval.

Educating employees on the right way of taking measurements cuts down errors and enhances productivity. Periodic retraining of the staff guarantees the maintenance of standards of the measurement as new personnel are hired or when there is a change of requirements of measurement.

Records of measurement processes and criteria make a point of reference towards measuring similarities. This record is essential especially in companies having numerous outlets or employees to handle the measurement activities.

Cost Implications of Accurate Box Measurement

The correct measurement of boxes has a direct influence on shipping pricing since much of the cost is based on the dimensional weights, as well as the carrier rates. Boxes with incorrect measurements may provide surprises in shipping fees or completely rejected shipments that have to be repackaged and will cause an extra waste of time and money.

It also influences costs of inventory management because proper measurement of the available boxes is taken into account. Better and accurate measurements of boxes enable maximized utilization of the storage space and efficient running of the warehouse. Such efficiency may lead to major cost saving of businesses having large amount of shipments.

Some of the issues surrounded on insurance claims and damage disputes include the proper packaging of items that include the use of correctly sized boxes. Claims processes can be aided with the right documentation of measurements, and right packaging habits can be demonstrated.

Conclusion

To deal with shipping and logistic actions, one should master the art of measuring shipping boxes. It takes meticulousness, appropriate equipment and knowledge of trade practices. With the help of this complete guide, it is possible to make precise measures resulting in the process of shipping products without spending a lot of money and ensuring the protection of products and their safe operations.

It is worth recalling that Box dimensions are always the internal dimensions, in length width height order and are made to manufacturing tolerances. The investment in the right metering instrument and developing a standard procedure of measuring will provide a reward of fewer shipping expenses and happier customers.