Introduction

Mangoes are referred to as king of fruits justifiably. Their juicy, tender meat, intoxicating scent and colorful appearance have been appealing to the taste buds all over the world since centuries. Since the times of street vendors in Mumbai, up to the expensive grocery shops in New York, the mangoes have become the favorite tropical fruit across the world, since more than 50 million tons are consumed worldwide.

However, how does this sensitive tropical gem find its way out of the lonely orchards to your nearby supermarket and retain its quality, taste, and nutritional content? This detailed tutorial covers the whole process of the mango supply chain, starting with the various methods of harvesting and special packaging techniques all the way up to logistics of transport, storage needs, and preservation techniques and techniques that guarantee the delivery of these precious fruits to the consumer in their original state.

What Is a Mango? The Basics

Mango (Mangifera indica) is of the same family- anacardiaceae, which includes cashews and pistachios. The growth of this tropical fruit tree was first in India more than 4000 years ago and became a part of Hinduism mythology and Buddhism tradition before spreading to all parts of Southeast Asia and ultimately to all parts of the world where there is a tropical or subtropical climate.

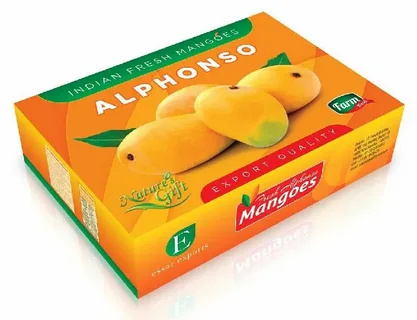

Modern varieties of mangoes have been exemplary in diversity of size, shape, color, and flavor. In international trade, the high-performing variety of the tomato, the red-green color and light taste of Tommy Atkins dominate the market because of its good shipping characteristics. The Kent mangoes have a sweeter, more fragrant bite with the golden-yellow flesh whereas Haden varieties have the perfect combination of sweetness and acidity. The others that are popular to cultivate are the large size with a low percentage of fiber, Keitt as well as the honey-sweetened Ataulfo. Every type of variety has to be handled and packaged differently depending on its properties, pattern of ripening and intended markets.

Harvesting & Initial Handling

Effective packaging of mangoes starts a long time before the fruit is packaged. Mango cultivation on a professional level assumes harvesting at the optimal stage of maturity, which is when the fruits have reached full size yet are hard and a little underripe. This time is to provide maximum shelf life during transportation but still to be able to perform the natural ripening process during distribution.

Mangoes are immediately taken after picking and subjected to critical initial treatments. The sap produced by the stem that appears as latex should be cleaned, it may leave a stain on the skin as well as lead to the degradation of quality. A variety of commercial processes can be used after harvest such as fungicide dips, hot water treatment at a very exact temperature (usually 46-50o C over a given period of time) and in certain instances a wax coating can be applied to minimize moisture loss and improve the appearance.

Handling at such tender stages is highly instrumental to the packaging success. the slightest bruises or pressure spots caused at harvesting may grow into significant quality problems during transportation and therefore taking proper steps in the collection and prompt proper handling of the harvest is necessary to preserve the integrity of fruits across the whole supply cycle.

Packaging: How to Protect Mangoes

Mango packaging is a high-level protection, ventilation, and cost-saving. Most commercial packaging uses corrugated cardboard boxes that have holes that are ventilated and are specially created so that air can flow freely through the container without subjecting the fruits to mechanical damages. On average 4-6 kg of mangoes can fit into these boxes based on the type and the market they are destined to.

In these cartons, protection of the fruits will take a precedence. The professional packaging business uses different types of cushioning like molded pulp trays, expanded polyethylene foam net, or the conventional packaging materials such as wood wool or straw. Mangoes can be individually wrapped in tissue papers or in protective foam wraps in order to avoid direct contact of fruits with fruits that can speed up the process of ripening and expose them to risks of damage..

Contemporary packaging plants adhere to high standards of sanitation during the packaging. The quality of all packaging containers is checked, the working areas are cleaned daily, and controlled temperatures eliminate premature ripening conditions. Premium markets are oriented to single-layer packaging arrangements whereas carefully stacked arrangements can be applied to domestic distribution where the distances covered by the transport and the control of the handling are more restrained.

Transport & Supply Chain Management

Mango transport logistics is a multimodal work based on the distance, urgency, and market value. In domestic distribution, refrigerated trucks, which have accurate temperature controls and are properly ventilated, are usually used. Ocean shipping in refrigerated containers (reefers) is cost-efficient to transport bulk products to the global market, whereas air freight is relevant to highly competitive markets that demand delivery of high-quality fruit in the shortest time possible.

Container transport needs more than just simple refrigeration of the atmosphere. Controlled atmosphere (CA) containers regulate the amount of oxygen and carbon dioxide in the atmosphere to delay the processes of ripening, and the optimal amount of humidity prevents dehydration without promoting the growth of fungi. The sophisticated monitoring systems can measure the temperature, the humidity, and the gasses levels during the transportation process and warn the logistics teams about any issues that might affect the quality of fruits.

Effective supply chain management requires a smooth communication between manufacturers, package keepers, shippers, and wholesalers. The cold chain integrity should be done at all stages of packaging and all the way to the final destination which necessitates special machines at ports, distribution centers and retail sites. Crisis management procedures deal with the possible upheavals such as equipment failure, delay by customs, or extreme weather conditions that might impact on the quality of fruits.

Conditions for Storage & Transport

To ensure the finest environmental conditions in the mango supply chain, there should be the strict control of various factors. The preservation of quality is based on the management of temperature where most of the commercial varieties should be transported and stored at the same temperatures of between 10-13 o C. Lower than 10 degrees C will cause chilling injury that takes the form of skin pitting, abnormal ripening, and loss of flavours, whereas higher than 15 degrees C hastens ripening and has very short shelf life..

The humidity regulation is also very essential and the ideal relative humidity measure is between 85-95. Reduced humidity results in too much moisture loss and hence skin dehydration and loss of weight whereas high humidity leads to fungal growth and decay. The contemporary transport containers are fitted with advanced humidity monitoring mechanisms in which the moisture levels are regulated according to the rate of respiration of fruits and the external environment.

Ventilation is essential to avoid carbon dioxide and ethylene gas build up both of which are naturally produced during the respiration of fruits. Poor circulation of air may result in anaerobic environment which causes the development of off-flavors as well as decay. Average commercial transport systems have an air exchange rate of 20-40 cubic meters per hour per ton of fruit, which ensures homogeneity in the gas composition across the cargo space.

Risks, Spoilage & Loss Prevention

Mango transport faces a lot of threats that may lead to severe quality losses and financial losses. Mechanical injury is the most direct danger, and even a slight bruising during manipulation opens paths to pathogenic microbes and promotes increased ripening in the affected areas. The damage caused by the pressure during improper stacking or container movement during the transportation process can ruin the whole shipment, so it is crucial to pack products safely and follow the right loading guidelines.

There are constant challenges in the supply chain due to biological threats. Anthracnose is a fungal infection and manifests in the form of dark spots on the skin and flesh and can be easily spread in warm and humid conditions. Fruit flies and weevils can contaminate shipments, especially those of the areas where the quarantine measures are not sufficient. These problems can be eliminated before developing into a significant loss with the help of post-harvest treatments and constant monitoring.

Environmental and chemical hazards consist of contamination by cleaning agents, fuel vapors or other cargo in mixed-load containers. The variation in temperature may lead to condensation which encourages fungal growth whereas exposure to ethylene by other fruits in the process of ripening may result in premature maturing. Natural aging that leads to quality degradation encompasses over-ripening, texture degradation and a progressive degradation in nutritional values with prolonged storage.

Quality & Shelf Life

There is a set of visual and tactile qualities that are to be measured in order to determine mangoes of high-quality. Premium fruit has smooth and unblemished skin of the appropriate color of the fruit, firmness, yet gives in to slight pressure, and a sweet, fruity smell found close to a stem. The skin must not have dark spots, cuts or softness to denote internal damage or atrophy.

Most commercial mango varieties are of acceptable quality even after the harvest under the best storage and handling conditions (2-4 weeks). Shelf life is however very different depending on the original state of the fruit, the handling and storage conditions. This may be prolonged with regard to proper packaging and cold chain management, but any disturbance in favorable conditions may shorten shelf life drastically.

Some of the factors that usually reduce the shelf life include mechanical damages caused during handling, temperature abuse, improper humidity regulation, and exposure to ethylene gas. Education of consumers about suitable selection and home storage can also gain out of increased eating value and minimize the waste of mangoes that have achieved suitable treatment during the commercial supply chain.

Intended Uses & Culinary Applications

Mangoes have many food uses that affect the packing and handling needs. The fresh eating business is the leading market where fruits must be of ideal looks, good maturity, and increased taste development. Fruits with minor cosmetic flaws can be used in processing applications, such as the production of juices, canned fruit, chutneys, preserves, etc., which require a uniform quality and flavor profile.

Mangoes are very versatile as they can be used in very basic ways like taking them fresh or they can be used in fine culinary ways in both sweet and savory food. Tropical foods use mangoes in curries, salads and rice, with other uses as desserts, both traditional fruit salads and molecular gastronomy. The beverage uses include fresh juices, smoothies and alcoholic cocktails that put into use the strong taste and smell of the fruit.

Mangoes are a very valuable nutritionally with a high level of vitamins A and C, dietary fiber and antioxidant agents such as beta-carotene and phenolic acids. As these health benefits coupled with natural sweetness and tasty texture have been leading to growing demand in health-conscious markets across the world.

Global Supply & Countries of Origin

Mango is produced in the tropical and subtropical parts of the globe with India being the largest producer with a production of about 20 million tons per year followed by China, Thailand, Indonesia and Pakistan. The key exporting countries are India, Thailand, Mexico, Peru, and Brazil which deal with special varieties and target different regional markets depending on their geographic proximity and trade relations.

Availability of food by season also differs greatly by the region, with complicated global supply trends. Northern hemisphere producers also harvest between March and August whereas southern hemisphere producers harvests between October and February. This seasonal complementing enables year round supply in prime consumer markets, however, with complex logistics coordination and product selection.

Growing challenges are being placed on international trade in the form of tighter phytosanitary standards, rising quality expectations as well as competition by the local and regional suppliers. Traditional growing areas, harvesting schedule are influenced by climate change whereas changing tastes and preferences among consumers necessitate organic, sustainably grown and specialty varieties that demand different packaging and handling methods.

Tips for Consumers: Selecting, Storing, Ripening at Home

Mangoes can only be successful to consumers when they are selected well at the retail outlets. Find those fruits which are heavy in comparison with their size, have smooth skin and no wrinkles or soft spots, and a sweet, fruit-like smell just above the stem. Mangoes should never have dark spots or cuts or mushy spots because these are signs of internal damage or old age.

By placing mangoes in paper bags with other fruits that produce ethylene such as apples or bananas in a room temperature, one can hasten the process of home ripening in mangoes. When mangoes are ready they can be stored in the refrigerator at 2-5 days to delay the further ripening. Unripe mangoes should never be refrigerated because coldness will not allow it to develop the appropriate flavor and may permanently destroy the quality.

Mangoes that were cut have to be refrigerated in capped containers immediately and cannot last longer than 2-3 days to be of good quality. To inhibit the process of browning, a little citric acid or lemon juice can be added to help prolong the storage life. Home handling of commercially packed mangoes is done in the most appropriate way to achieve optimal investment on good packaging as well as transport systems used during supply chain.

Regulations, Certifications & Standards

The international mango trade is governed by complicated regulatory systems that govern the prevention of the transmission of pests and diseases, as well as providing quality and safety of product. Phytosanitary certificates confirm that imports comply with pest control measures and healthiness of imports to the country of imports. Some countries dictate the post-harvest procedures, inspection procedures and certification procedures to be followed prior to mango imports.

The quality standards differ depending on market but usually cover size, color, firmness and defect tolerance. The HS codes are a standard used in international trade to categorize types of mango and quality grades to make it easy to handle customs and statistics of trade. Organic certifications and fair trade designations, as well as other specialty classifications, require extra documentation but frequently command extremely high prices.

Adherence to the changing rules presupposes the continuous expenditure on the treatment facilities, documentation system, and quality control procedures. The effective exporters have strong ties with the regulatory bodies in both source and destination nations whereby, packaging and handling guidelines are in compliance with all the stipulated conditions to their target markets.

Conclusion

The path that the mangoes take through tropical orchards to the consumer tables is one of most complex supply chains in world agriculture that needs the accurate arrangement of the harvesting, packaging, transporting, and storage of the product. Maintaining the best temperature and humid conditions, avoiding mechanical and biological damages, and regulatory compliance are all required to achieve success in the process. This system is based on proper packaging, which preserves the sensitive fruits and leaves them with the required ventilation and the minimum of information required by the handlers and consumers. Whether you are a producer who wants to reduce the rate of quality retention, a logistician in charge of cold chain integrity, or a customer that wants to choose the best mango, the knowledge of these complicated processes will allow you to make a better decision that helps to minimize wastage, maintain quality, and ensure that this wonderful fruit will keep satisfying mouths across the globe.