The folding cartons and the rigid boxes options of the product package can affect the brand image and cost, and customer experience considerably too. It is critical to understand the key This full guide will assist you in understanding the differences between rigid box and folding carton packaging, so that you can wisely choose the most appropriate packaging solution that fits well into your product and brand requirements. The differences between the two popular packaging options to make the correct choice, depending on what your business and target customers desire to see.

What are Folding Cartons?

Folding cartons are made of lightweight materials and are cost-effective and efficient paperboard packaging solutions. The multifunctional containers have become popular in the packaging industry due to their cost-effective nature and convenience.

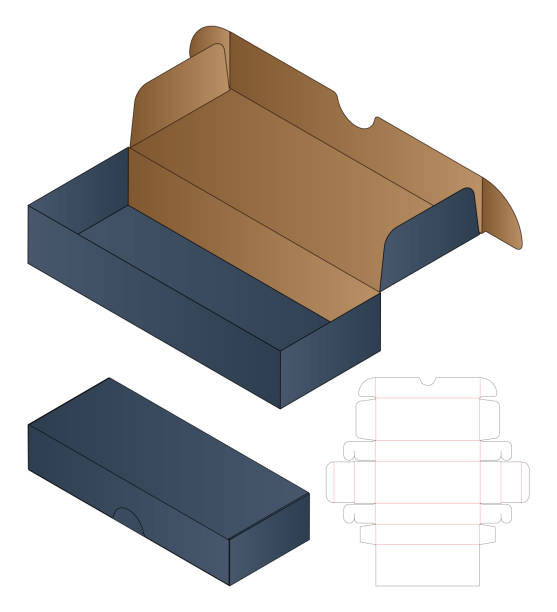

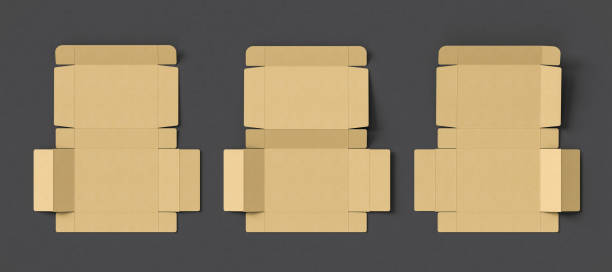

Definition and Structure Folding Cartons – are made of single sheets of paper board that are prepared, die cut, and scored to make folds. The benefit of this type of packaging relies on the fact that it is collapsible, so these boxes can be folded and kept in storage, and when the need arises to use them, they can be easily expanded.

Common Applications: Typical: The uses of Folding cartons have some common applications that you can find in nearly all industries. They are utilized as the default option on the packaging of the cereals that comprise so many of what we see on the shelves at the grocery stores, on the packaging of pharmaceuticals and drugs that contain and protect them, and on the millions of smaller consumer products that are daily produced that we all just take for granted such as cosmetics, electrical accessories, computer units, and phones. They could even be extended and therefore applied to goods that could require a functional and retail-friendly package.

Manufacturing Process Production is effective. Brand graphics and product information are printed on a pre-existing paperboard and die-cut precisely to mould them into a box. The flat paper is folded in such a manner as to look like a container with the help of strategic scoring. These cartons are manufactured and shipped in a flat form to the manufacturers or the retailers so that they may be assembled when they are needed.

Costs – since the costs that can be avoided in certain companies can be enormous in the sense that they can be modeled, the combination of light content and space transportation in a manner that will be able to visualizing the savings of cost savings that will be achieved. When transported in a flat form, they save significantly on the volume of products being transported, thereby saving even more on the logistic expenses. Moreover, it can be produced easily and less material is needed to produce it, therefore economical in localities that have a low profit margin.

Customization Options – Despite this simplicity, folding cartons contain a fantastic possible dimensions of customization. They can be printed onto the cardboard surface itself with decent graphics, giving off dynamic colors and detailed designs. Finishing and various types of coating as something which may be directly taken as something which will add aesthetic value, and also to protect it and grant it long life and moisture, and wear resistance are also possible.

What are Rigid Boxes?

Rigid boxes constitute the high end of the packaging solutions spectrum, and come with greatly enhanced durability and a more prestigious presentation that immediately connotes quality and luxury in the minds of consumers.

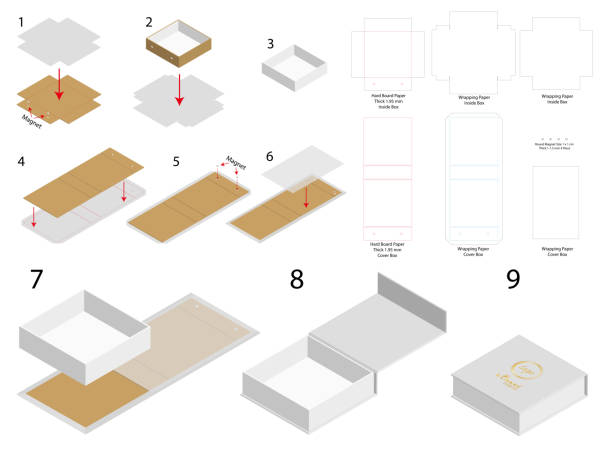

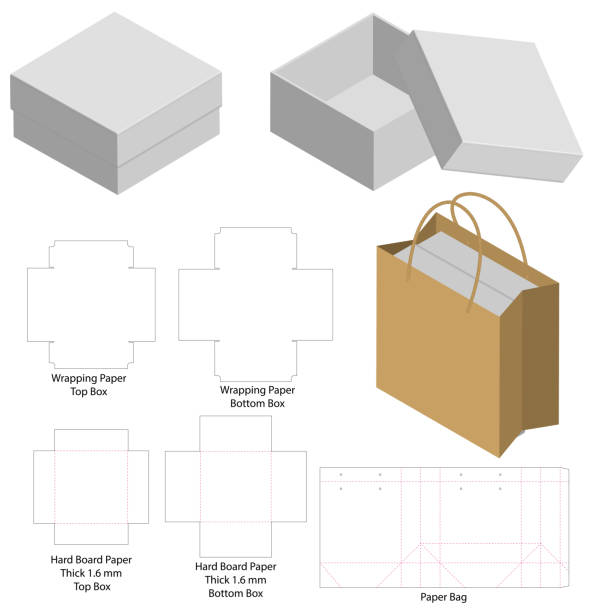

Definition and Construction: These are made of thick chipboard or paperboard over which decorative or printed paper is wrapped. The difference with their counterparts with folding is that these boxes do not fold back to their original shape and form. The central resin gives incredible strength, and the outer cover gives the beauty and luxury brands want.

Target Application: High-end jewelry, luxury goods, premium apparel, upscale and sophisticated electronics, and high-level gift items use rigid boxes as their packaging. Cosmetics, wine, and technology are all industries that will often use rigid boxes to add a perceived value and memorable unboxing experience.

Manufacturing Process: Rigid boxes manufacturing is a somewhat longer process than that of folding cartons. The manufacturing process creates the finished products as a fully assembled box consisting of a chipboard core that is shaped and a decorative paper that is precisely glued in place. The pre-assembly provides structural integrity at the expense of the box’s ability to collapse during transportation.

Investment Considerations: The solid boxes sell at a higher price because of the premium quality of materials they use and due to the labour-intensive manufacturing process. Board construction of chipboard and special glues, as well as assemblies of complex work, lead to an increase in manufacturing costs. Nevertheless, such an investment can be returned on many occasions with superior brand image and consumer satisfaction.

Premium Customization Features: Best Luxury Customization Finishes Luxury options are a strong suit of rigid boxes. High-end finishing like embossing, debossing, foil stamping, and spot UV produces tactile and visual effects that stimulate customers. Most rigid boxes also include added functionality such as magnetic closures, ribbon pulls, foam cushions, or interior compartments, which further add value to the user experience, as well as protection of the product within it.

Key Differences: A Detailed Comparison

Understanding the fundamental differences between folding cartons and rigid boxes helps clarify which option best suits your specific needs.

| Feature | Folding Cartons | Rigid Boxes |

| Material | Lightweight paperboard (typically 12-24pt) | Thick, durable chipboard (3-4mm) wrapped in decorative paper |

| Structure | Foldable and collapsible design | Pre-assembled, maintains permanent shape |

| Cost | Economical pricing due to material efficiency | Premium pricing reflecting quality materials and labor |

| Graphics Application | Printed directly onto paperboard surface | Applied via printed wrap-around paper or labels |

| Storage & Shipping | Ships flat, significant space and cost savings | Requires full dimensional shipping space |

| Appearance | Clean, functional, retail-optimized look | Elegant, luxurious, premium presentation |

| Setup Time | Requires assembly by end user | Ready to use immediately |

| Durability | Adequate for most consumer products | Superior protection for valuable items |

| Brand Perception | Professional, accessible, mainstream appeal | Luxury, exclusive, high-end positioning |

Which Packaging Solution Should You Choose?

The choice of which of the two to use, folding cartons or rigid boxes, will rely on a number of key variables, such as your target market, budget restraints, brand positioning, and product needs.

Choose Folding Cartons When:

The best in business-wise and operation-wise are folding cartons. They are aware of large markets where professionalism and cost will need to be factored in. When you have products in the product line that are retailed and demand the same level of standardized shelf presence, then folding cartons are your best choice.

These are very useful packages when the product to be packed is enjoying the benefits of automation during packaging. What makes bulk production facilities like it is their ease of assembly and low storage requirements. Folding cartons are commonly used to perform new product or market testing due to the lower unit of risk and low financial risk involved.

Numerous industries utilize folding cartons as primary packaging, such as food and beverage, pharmaceuticals, personal care, and consumer electronics. The reason is that they are more appropriate for regulatory compliance, and adding a tamper-evident feature is most appropriate in regulated industries.

Choose Rigid Boxes When:

Rigid boxes are highly preferred in cases where brand differentiation and top positioning are major factors to consider. When your product is sold at higher prices, aiming at more affluent consumers whose profile is linked to a higher quality and a good presentation, then rigid boxes offer the proper message to resonate with the idea of a high price.

These packages are superior in providing an unforgettable boxing experience, which creates buzz in social media and the creation of customer loyalty. Designer brands in cosmetics, jewelry, watches, premium spirits, and in high-end handsets use stiff boxes to remind of what they represent and warrant higher prices.

The boxes provide better product protection, such that they are great choices when handling fragile and valuable products or products that are technically advanced and highly sensitive. The structural strength assists in avoiding damage, which may lead to returns and replacements or customer dissatisfaction.

Making the Right Choice for Your Brand

Whether to use folding cartons or rigid boxes is ultimately up to your target market and business objectives in addition to the nature of the product. This decision should be made based on your brand positioning, budget constraints, volume, and customer expectations.

In Crown Win Packing, we understand that there are different needs associated with different products, brands. We are a very experienced team and can help you to analyse your options and come up with personal packaging solutions that can suit your needs. We can develop cost-efficient folding cartons and distribute them by mass market or high-end rigid box, where products are placed at the end of the scale.

You should keep in mind that the initial physical touch the customers will feel with your brand is usually packaging. Optimise it using the optimal solution, which is based on your values and as per the expectations of the customers. The packaging has already become the fashionable marketing instrument and the appropriate selection of packaging not just keeps your very own product secure but can actually be the deciding element among the competitive markets.