Make the first impression, explore jewelry packaging, and the first contact with it can make the sale even before the opened bead. Although basic structure and quality material provides the background, it is the surface finish that makes a good box a memorable box. Foil stamping, embossing, and soft-touch lamination are unique since they are available with sophistication, achieved by being subtle in nature – without screaming.

It is not the application of these finishes that is the problem but rather the control of these finishes that allow all the boxes in a 5,000-piece order to all feel the same. When properly handled, they strengthen professionalism and brand loyalty. With execution slippage, even the slightest errors are highlighted on the luxury background.

Why Finishing Choices Shape Perceived Jewelry Value

The customer appoints judgment of jewelry packaging within a few seconds – in sight, touch and durability of the box. Reflective finishes humbly hint at “this brand is attentive to details.”

These are the factors that we have observed affect perception on our factory floor:

- Visual difference = better brand memory (the bold gold logo stands out on the otherwise dull black background)

- Surface texture/instant high quality feel (velvety soft-touch encourages caressing)

- Edge accuracy | evidence of production rigidity.

- Finish life cycle → assured that the box will not be damaged upon delivery and re-opening.

The luxury jewel brands succeed when finishes get old and not old within a very short period of time.

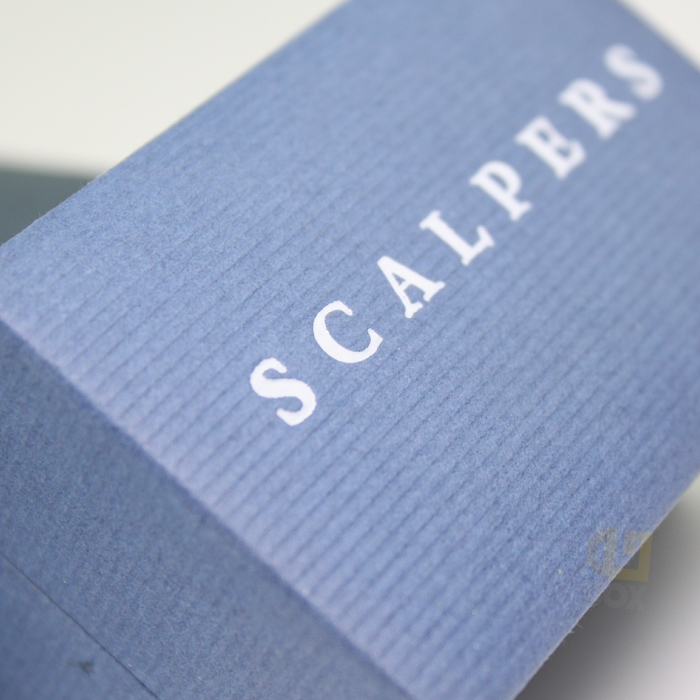

Foil Stamping: Adding Controlled Shine and Brand Focus

Foil stamping is a heat-resistant break in reflective accents on a thin metal or pigmented base applied to the fabric by heat and precision dies, making it look like there is a spotlight cast on it.

Benefits for Jewelry Boxes

- Provides reflective surface of gold, silver, rose gold or matte metallic.

- Not too many patterns or monograms without too much clutter to the design.

- Goes well with dark or rough boards to achieve the subtle luxury.

Practically, we would foil any focal point of the piece; lid logos, corner accents or inner lid messages because restraint leaves the jewelry as the star.

Key Production Requirements

- Enhanced alignment of the dies (tolerating 0.5 mm cutting off symmetry)

- Distribution of even heat and pressure.

- Cleave foil margins (no bleeding, no halo effects)

Tilting causes distorted shone or lost sharpness to be seen instantly, immediately reducing the perceived quality particularly on high quality rigid jewelry boxes.

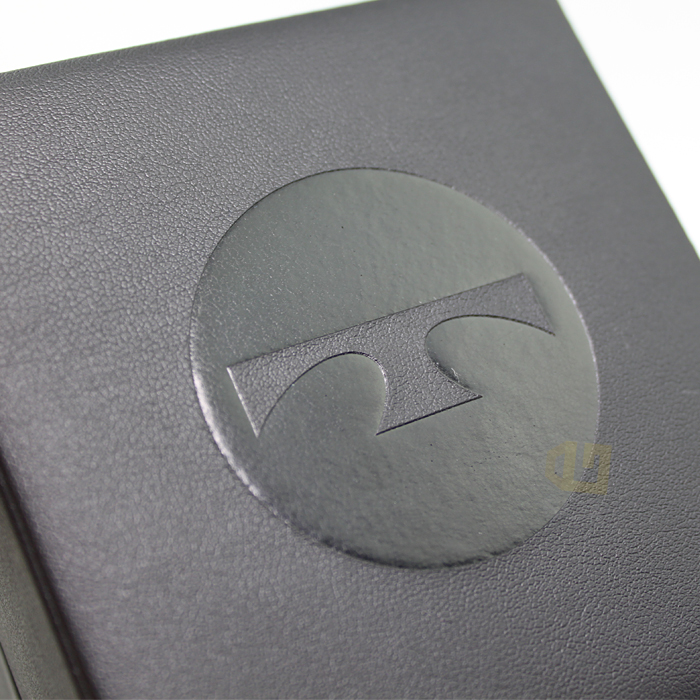

Embossing: Building Tactile Depth and Quiet Craftsmanship

Embossing lifts the preferred areas of the design higher than the rest and gives it a dimension which can be touched.

Why It Works So Well for Jewelry Packaging

- Provides a micro 3D texture that sends a message of human touch.

- Improves appeal to touch, not color necessary.

- Develops emotional attachment (fingertips do not forget raised logo)

Essential Attributes for Success

- Control of depth – shallower than that, it becomes flattened; more so than that, it may crack the board.

- Edge sharpness – sharp edges depict accuracy.

- Surface stability – board being of constant thickness ensures that results are even.

Embossing requires a strict control of the processes. A difference in the density of the paperboard or a fluctuation in pressure is immediately manifested in which case in-house tooling and a multi-stage check is sacrificable to achieve consistency in the outcome.

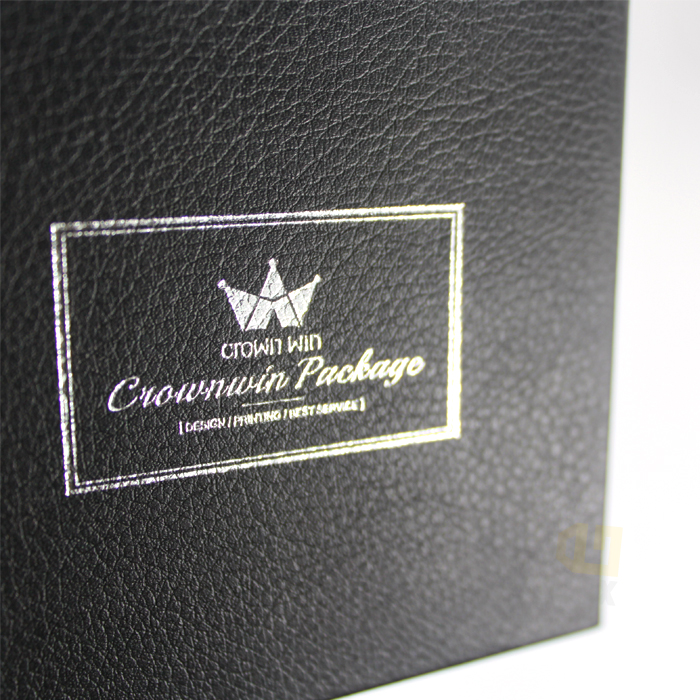

Soft-Touch Lamination: The Velvety Finish That Feels Expensive

Soft-touch lamination puts on a rubberized solution that is matte on surfaces making them to appear smooth and approachable.

Core Advantages in Luxury Jewelry Boxes

- Eliminative of glare and much better conceals fingerprints than normal matte.

- Gives a soft velvety hand-feel that customers would relate to premium products.

- Increases resistance to scuffs, scratches and normal wear.

Best Practices from Experience

- Works well with minimal designs – allows subtle foil or embossed objects to shine through.

- It matches great with dark coloring (black, navy, charcoal) to be modernly elegant.

- No excessively applied; the magic of touch disappears when all the surfaces are covered in the same way.

Properly cured and used, it will retain its feel of softness even months after being handled, essential in the retail display or e-commerce returns.

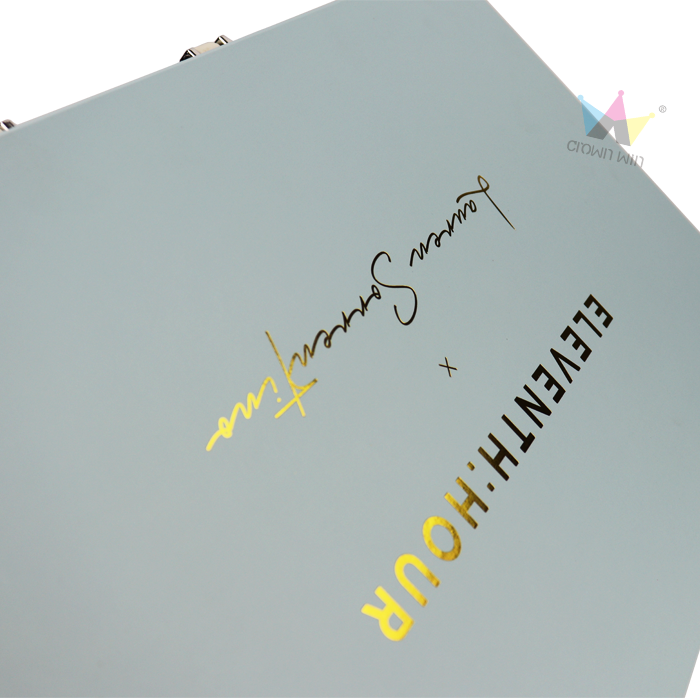

Smart Ways to Combine Finishes Without Overdesigning

Lots of our jewelry customers desire several tools, still, balance defines the difference between the high quality and the messy.

Combinations we have been proven to make:

- Foil stamping + embossing → raised metallic logo with sharp edges to have the maximum effect.

- Embossing + soft-touch lamination velvety matte layer-on-layer dimensional texture 5

- Foil minimum on soft-touch surfaces → slight lustre against smooth ground.

The guiding rule: finishes should support — never compete with — the jewelry inside. For custom ring and necklace packaging boxes, in this case, the question: What do you want the customer to experience before they even open the lid?

Manufacturing Consistency: The Hidden Key to Finishing Success

Even the prettiest sample can be no more than a mere showcase, but the real luxury is run-to-run reliability.

Decolds compose the problems:

- Misaligned printing displays spectacularly when under foil.

- Lack of uniformity in board thickness destroys embossing depth.

- Inadequate adhesion is caused by poor lamination which results in peeling in the long run.

Our approach to reduce this at Crown Win include climate controlled conditions, years of experience in the operation of the operators, and the use of multi-level quality control (raw foil inspection till the end tactile inspection). The brands who make a judgment based on only the prototype will surely find out how far they will go in actual production – we can prevent this by creating uniformity in all the steps.

Common Finishing Mistakes We See in Jewelry Packaging

These traps include even the experienced buyers:

- Using excess techniques: → verge of visual noise and increase in defects.

- Pursuing meandering to uniformity → sophisticated foils on curved areas regularly tend to fade.

- Ignoring wear in the long term aspect → Certain soft-touch recipes pill or fade when heavily handled.

- Passing on scalability validation → beautiful small-batch finishes break at 10,000 units.

The best jewelry boxes are those which are modest: a single or two finishes superbly done out do a hundred dribbling ones.

Conclusion — Let Finishes Reinforce Your Brand Story

Foil stamping, embossing, soft-touch lamination is not new ornamentation, but rather an instrument to communicate silently quality, care, and consistency.

Thoughtfully selected and strictly supervised, they make packaging look and feel like an accessory to the jewelry itself: luxurious, textured, and long-lasting. Finishing is another composite never permitting to be an afterthought, but a component of manufacturing, where the elite experience that customers will talk about is continually offered.

In the case you can develop or are making a modification to jewelry packaging and but you require finishes to work in a prototype-to-full production way, then we are on hand to help such a thing happen.