Meta Description: Learn everything about die lines and dielines used in the packaging process and packaging design – along with their definition and creation. Read on how dielines will guarantee flawless production of packs, their variety, advantages, and optimum practices that will occur in the year 2025.

What Are Dielines in Packaging Design?

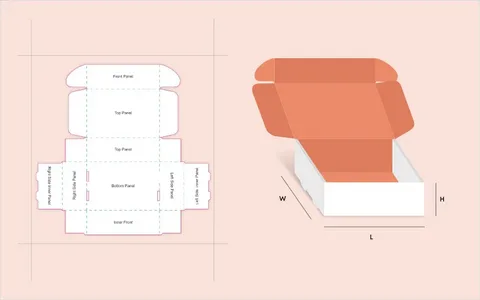

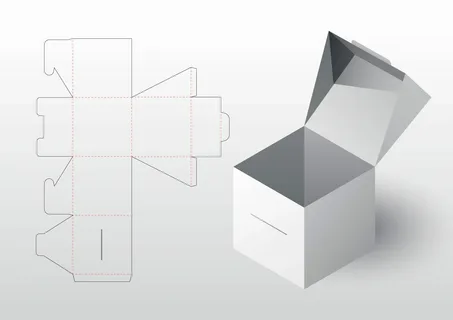

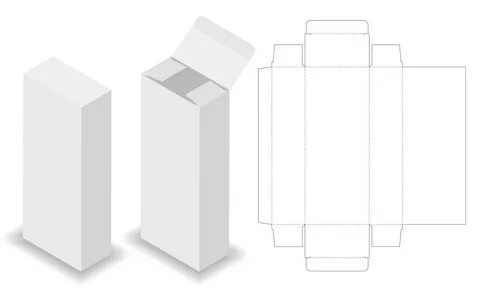

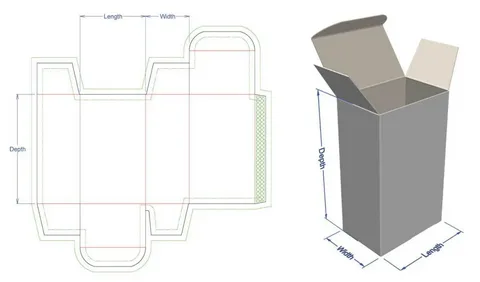

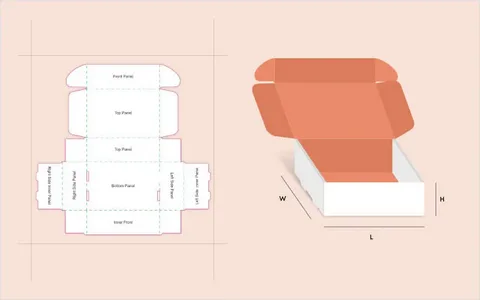

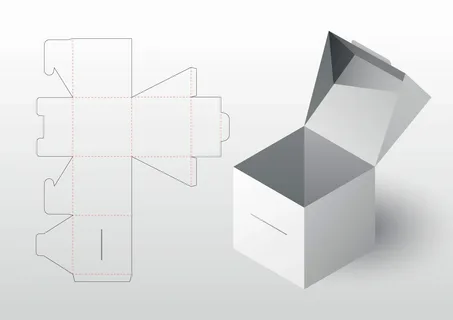

A dieline is a basic outline of how a finished three dimensional product is to be created out of flat packaging materials using the die cutting process . In the packaging and printing industry a dieline is a blueprint which makes sure that the design of a physical package fits properly into a layout before it can be made into a product creation process. The technical drawings have become the most important measure of communication to the designers, manufacturers, and printing units in the quality control process.

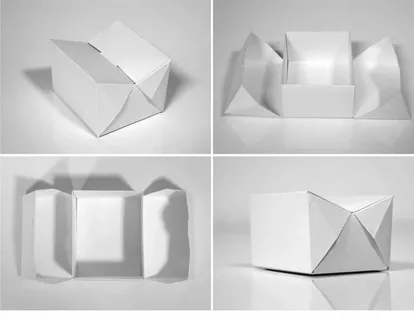

A dieline in packaging A dieline is a flat template describing exactly where the cuts, folds and edges must fall in order to produce a finished design on a package. It should be regarded as a blueprint or plan of your architectural design with customizable dimensions pocket folders, without it your fancy packaging design would never get out of the drawing stage. Dielines also make creative ideas manufacturable where every detail concerning folding, cutting, and assembly points is clearly outlined.

This is so because the word dieline is a historical accompaniment of die-cutting, through which packaging materials are cut and shaped using steel dies. Contemporary dielines keep this tradition up but add complicated digital technologies and the accuracy of manufacturing processes involving die cutting machines flat diagram. They are the integration of artistic design and engineering expertise, hence becoming necessary in the effective production of packaging.

The Technical Components of Dielines die cutting process

The components of dielines are important to know to the person dealing with packaging design or production. The dieline is a form of design blueprint and it specifies how the packaging will be laid out. It also acts as a guide to designers and the production team to have all the visible graphics, which include cut lines, fold lines, safety lines bleed lines as well as safe zone marked on its flat surface before being subjected to production custom dieline.

Cut lines are those lines depending on which the packaging material will be torn or taken out completely. Such lines, including perforation lines, are usually depicted in definite colors or kinds of lines so that they could be distinguished against other things. Fold line – parts of the material in which folding marks for three-dimensionality will be formed by creasing or bending. Score lines indicate the locations where incomplete chopping can provide simpler bending like a claw without the material having to suffer.

Bleed areas cover more that actual final trim lines, which means colors and graphics will go to the very edge of the finished package with no white borders. The safety zones or margins are to be used as regards to areas where necessary text and graphics ought to lie on so as to not be cut off during production, ensuring an exact size few steps . The registration marks also assist in fitting the colors so that they appear perfectly matched and positioned during the multi-color printing processes custom boxes.

Why Dielines Are Essential for Packaging Success

The blueprint to realize your packaging vision and, therefore, of critical importance to numerous reasons is dielines since dielines convey the sizing, scale, and dimensions of the final product. They make sure that everything is at its proper place which includes graphics, pictures, text for product packaging .

Lack of appropriate dielines exposes a packaging project to a myriad of risks such as wrong positioning of graphics, wrong measurements, and errors in the manufacture of a packaging which may cost thousands of dollars to redo crucial step. Dielines also make production a guessing game in custom packaging because manufacturers have precise requirements in all package assembly areas; this is due to production ready dielines.

Consistency on production runs is also established through professional dielines. Regardless of whether you are producing 1,000 or 100,000 units, dielines will ensure that the package will look and feel exactly the same way. This uniformity is essential in recognition of brands and customer confidence. Moreover, dielines allow estimating the cost as they give a specific amount of material and manufacturing requirements to be exact in cost estimation.

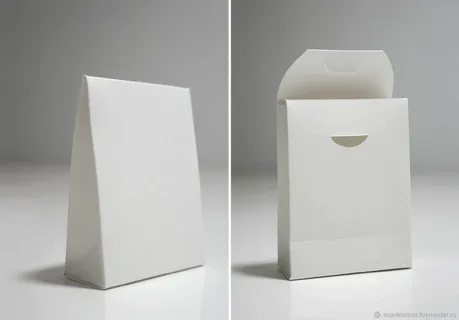

Types of Dielines Used in Modern Packaging

Specific dieline strategies are needed to take on various packaging formats. One of the most typical folding carton dielines includes tuck end boxes and anything cereal box to die cutters for pharmaceutical dielines. These dielines are usually high in folding complexity and incorporating a number of panels that must fit together precisely where assembled.

Corrugated Box dielines are aimed at addressing shipping demands and structure stability. They have such characteristics as the consideration of compression strength, the possibility of stacking, and cushioning protection elements. These dielines find consideration of the grain patterns of the corrugated material to provide maximum strength as well as folds.

Flexible packaging dielines process films and laminates, and pouches, bags and wraps. These dielines should allow space for artwork, heat sealing, tear notches, wrapped paper, and barrier layers. Dielines covered by Label include everything, simple product labeling, complex multi-layered structure with special adhesive needs and application procedures.

Digital Tools and Software for Dieline Creation

The process of creating dielines in modern use is highly dependent on dedicated software that is programmed to target packaging professionals. The most commonly used design software in terms of dieline design is Adobe Illustrator which employs highly accurate vector-based tools and has a consistent volume of customization available. Illustrator is also favored by many packaging designers as the flexibility and compatibility between Illustrator and the rest of the applications in Creative Suite.

Industry-Specific Packaging software tools Industry specific tools for dieline design to 3D visualization software exist e.g. ArtiosCAD, Kasemake, Impact. Such platforms contain standard packaging format libraries, automatic folding simulations and formats ready-to-manufacture including different layers . They simplify the process of design and make it technically correct.

Online Dieline generators are the affordable options of smaller businesses or designers. Just log on and you have error-free packaging templates in a few seconds. There is no necessity of downloading any other software. The platforms also provide a base place of templates according to the size or the particular requirements that can be altered to produce the desired professional dieline, even by a non-specialist.

Best Practices for Professional Dieline Development

Execution of good dielines involves paying many technical details, as well as standards in the industry. Determine correct measurements and packaging specification by the supplier or manufacturer of your packets. Minute sizes of the error in the dimensions may create separate unsuitable-fitting or conveyable packages.

Have same weight and color of line in your dieline, and this in order to eliminate confusion upon production. The majority of the industry guidelines imply the use of specific colors to differentiate various types of lines: cutting lines, folding lines, and safety zones should be represented by different colors. Provide all technical details including materials and finishing specifications, assembly details and so on.

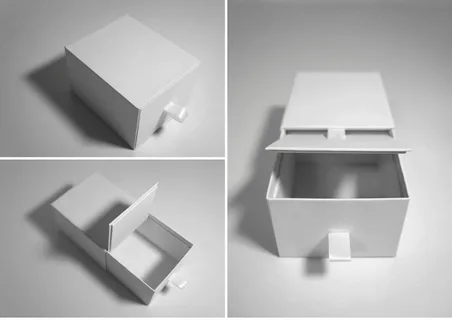

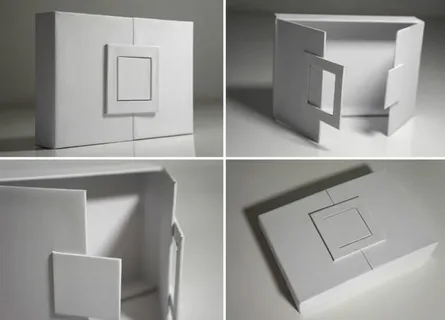

Dielines should be created at actual size (1:1 scale) so as to be accurate during the production. Whereas one might be tempted to work at smaller scales to display in the screen, they could present transformation errors during the last dimension. To eliminate the problem of guessing dielines, and before any substantial quantities are run, it is a good idea to create hand prototypes of your dielines in a flattened form.

Quality Control and Testing Procedures

High quality control eliminates expensive mistakes in production and will make customers satisfied. Start with computerized testing with 3D modeling software to analyze the problems which may be predisposed by a structure prior to conducting actual tests. Most of the newer dieline software packages provide folding simulation that will identify panel alignment or closure mechanism issues.

Actual prototyping will continue to be required to test the dieline accuracy. Prepare test packages composed of your own dielines with the very same materials, accurate measurements and processes that are to be used in the final production. The process gives details that the digital simulations may never have identified, like the grain direction effects of such a material or adhesive behaviour.

Make functional checks on packages so that they do what they should. Test closing and opening mechanisms, putting or taking out products and shipping strengths. The problems identified should be documented and dielines modified during the approval of the final production.

Common Dieline Mistakes and How to Avoid Them

Inadequate bleed zones are among dieline mistakes that are most common. Numerous designers fail to provide the template needed perly allow the bleed to appear on the finished package and have visible white edges due to not allowing enough bleed to appear to the selected production method. Look up your own bleed requirements as dictated by your manufacturer and incorporate mathematically described lines to carry a safety margin as well.

Mal-specification of fold direction may result in packages folding inverted-out, or generating structural weak points. Specifications of mountain folds and valley folds should be made distinct in your dieline specifications. Take common notation systems and offer reasonable signs of the fold way.

Failure to provide safety zones or position them incorrectly usually leads to the cutting off of critical text or graphics in the production process. Put in large safety margins and never fail to cross references dielines with your negative producer so that you know his or her particular production tolerances.

Industry Standards and Regulations

Being familiar with the industry precepts will help you make sure that your dielines satisfy professional standards and authoritative registrations. Performance testing of the dieline template and packaging guidelines are provided by the International Safe Transit Association (ISTA); testing of design of corrugated packaging is set by the Fibre Box Association.

The drugs and food packaging should follow the dictation of FDA laws which influence the dieline packaging branding. The regulations can impose certain safety seals or tamper-evident components or consideration to barrier material, which should be included into dieline specification.

Environmental laws are steadily affecting dieline work, especially in terms of recyclable status and use of materials. Make the dieline as waste minimising, sustainable and supporting a recyclable end-of-life.

Cost Considerations and Budget Planning

The complexity in dielines has a direct consequence on the cost of production, including die-cutting and material usage as well as the required labour to assemble. The less detailed and more geometric the shape the simpler it is to cut and as such is more cost effective to manufacture. Develop dieline specifications taking into count the cost implications.

Material efficiency has an impact not only on the cost but also the environment. Maximize dielines to reduce wastage in the production process by ensuring that the arrangement of the packages on the printing sheets or cutting layouts. It is possible to make substantial savings as a result of modest gains in material efficiency on large production volumes.

Custom die setup fees can run high, especially on uniquely shaped packages, or a complex package. When figuring your budget, factor these one-time costs, and see if modest designs of your dielines could just as well accomplish the same aesthetic aims at lesser expense.

Future Trends in Dieline Technology

Machine learning and artificial intelligence are already starting to trickle down to the dieline design with the optimization algorithms that are automatized and further developed. The systems are capable of considering thousands of possible dieline permutations to find the best mix of material utilization, strength as well as production cost.

Innovations are being promoted by the process of sustainability thinking in the design of dielines. New methods are aimed at minimizing waste of materials, enhancing recycling, use of biodegradable materials. Dielines in the future are bound to have the concept of a circular economy incorporated in the initial stage of design.

Review and approval of dielines Augmented reality and virtual reality technologies are transforming how dieline review and approval are done. With these tools, stakeholders are capable of viewing and testing the packaging designs without any actual production of prototypes, which shortens development processes and saves a great deal of time associated with creating prototypes numerous times.

Integration with Manufacturing Processes

The key to the effective dieline implementation is provided by the tight cooperation with the manufacturing possibilities and restrictions. Various methods of production have different requirements from the printing company , and they ought to be taken into consideration when developing a dieline. Digital printing systems might need the files in a different preparation to standard lithographic printing.

Possibilities of dieline design depend on the specifications of die cutting equipment. Being aware of what your manufacturer of equipment can produce regularly, can also ensure that your dielines are realistically produced without the used of any special tooling or special set ups.

The dieline specifications are used in quality control systems in the modern manufacturing plants, or the purpose of offering an automated inspection and sorting process. Such systems need the inclusion of reference points and quality control marks necessary in your dielines.

Conclusion

Dielines are the most important connection between the imaginative packaging design and the successful manufacturing process. They use abstract design ideas into specific technical statements which will allow consistent high quality output to be produced. Acquaintance with the principles, components, and good practices associated with dieline is necessary to people who dealt with packaging design or production.

The dieline technology has advanced and the process of professional package design has become more affordable in the packaging industry keeping in mind that the modern manufacturing demands precision. Whether it starts with a hand drawn template or a complex computer program, dielines have always played a crucial role towards the success of packaging. Although the cost of developing appropriate dieline design appears to be significantly large in the packaging production process final packaging , the benefits are worth the expenses, such as minimized production errors, effective quality control, and customer satisfaction final packaging.