Packaging jewelry is normally viewed as a case of one size fits all. Actually, rings, necklaces and earrings have very dissimilar requirements of box structure, insert design and internal spacing. What is a good package in one jewelry category can be a bad one in another, resulting in the package failing to protect, having a sloppy appearance, or a poor customer experience.

A good packaging of custom jewelry should start with the knowledge of how the physical properties of the different types of jewelry affect their packaging design. Accommodative Brands, which consider such differences early in its development, are in a position to realize consistent quality and long-term scalability.

Why Jewelry Type Should Drive Packaging Design Decisions

Pieces of jewelry can differ greatly in terms of size, shape, weight distribution and movement. The factors have a direct influence on packaging engineering.

pcjazz Packaging that is designed without accounting for the behavior of jewelry frequently ends up creating boxes that look pretty when trying them on but fail when shipping, storage, or when being reused.

Key Jewelry Characteristics and Their Packaging Impact

- Size and profile — Decrees inner depth and box proportions.

- Weight distribution -affects support and density of the insert.

- Movement potential- Influences retention and slot design.

- Fragility Protection requirements Dictate.

The choice on packaging should never be made based on the box, but the product.

Ring Boxes: Precision, Stability, and Compact Structure

Rings are normally small yet heavy pieces of equipment that have to be laid precisely. Ring boxes should not allow rotation and movement and they should display the ring in a purposeful and focused manner.

Core Design Priorities for Custom Ring Boxes

- Insert material (usually high density EVA foam or molded pulp) to make the band firmly hold the stones but do not compress them.

- Wide slots which have been cut narrowly and very accurately to allow repeated opening and closing.

- Small external size (mostly 2″2.5 square) to strengthen perceived value and make the experience of unboxing feel luxurious.

Since rings have traditionally been connected to gift giving and emotional value, any slackness or lack of fit within each box can be the cause of the atmosphere being destroyed within a short time.

Ring box packaging is successful when, structure and insert collaborate in developing stability with a minimal amount of bulk. At our factory, we have observed that brands have moved towards personalized ring boxes with customized inserts and the watch return rates have significantly reduced.

Necklace Boxes: Managing Length, Movement, and Tension

The challenge that necklaces bring is different; length and movement. Necklaces unlike rings, can move, twist or bend the ring unless adequately held.

Essential Features for Effective Necklace Packaging

- Embedded tracks With directed trails, or extended grooves, to lay out the chain flat and straight.

- Special demons (hooks, loops, or padded slots) should be designated where the clasp and pendant should be attached to minimize their movement.

- By having sufficient internal depth (usually 7″ 10″ length or square) to prevent chain or pendant pressure.

Common Necklace Packaging Risks and Solutions

- Chain tangling → Guided insert channels keep links separated

- Pendant shifting This is centred in slots or recessed compartments.

- Pressure damage → Internal depth and soft-touch linings controlled, creese prevented.

Packaging a necklace where movement is not controlled should always lead to broken presentation although the necklace could still be okay. Thousands of specifically designed and crafted necklace boxes with a cradle of the specific pendants have been made by us the difference in customer response is evident.

Earring Boxes: Balance, Symmetry, and Secure Holding

Earrings are usually very light but must show delicate symmetry in display. The packaging needs to keep the earrings straight and on view and not on a bent posture or pushed aside.

Design Priorities for Custom Earring Boxes

- Perfect mirroring with dual slot or post symmetrical insert layout.

- Soft but firm points of holding (foam posts, elastic loops, or recessed wells) which do not scratch.

- The shallowness of the depth in order to make earrings sit up and easy to see during the first opening.

Small deviations in earring position can be seen by the naked eye, which means that precision in the insert is especially valuable in regard to this type of jewelry item. In the case of stud or drop earrings, we have discovered that by making a tiny rotation in the slot angle; the pair will always appear professionally balanced.

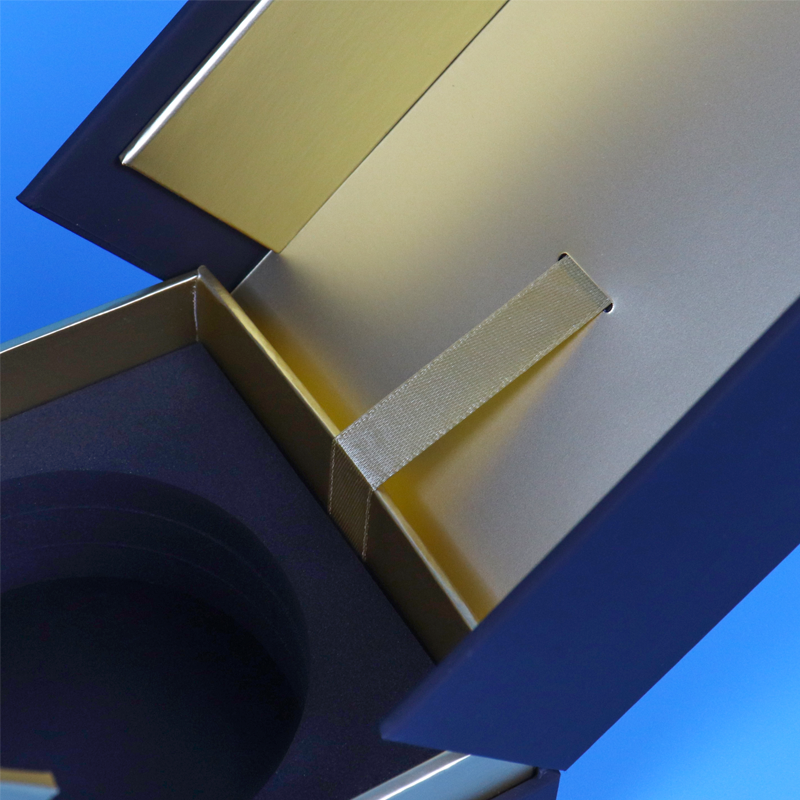

When One Box Must Accommodate Multiple Jewelry Types

Other brands are also trying to use standard packages by packing various jewels in the same box. Though it has the ability to simplify tooling and inventory, the strategy also tends to create compromises.

Trade-Offs in Multi-Purpose Jewelry Boxes

- With adjustable or removable inserts (e.g. removable dividers or combo slots).

- Increased internal room to provide variation in size and shape.

- Flexibility and stability maintained.

Assessing whether to package custom jewels in a standard or custom collection, the brand must consider the importance of low cost savings against the peril of lower presentation and protection functions. On mixed collections, we usually suggest hybrid designs with customizable inserts – but with high-value lines pure single-type boxes are the winner. To learn more about customized methods, check out our custom jewelry packaging solutions.

Manufacturing Considerations Across Jewelry Types

In terms of production, various designs of the jewelry boxes will need varying amounts of precision in their insert cutting, the degree of complexity in assembly, and quality control.

Key Manufacturing Factors by Jewelry Type

- Insert material tolerances Rings should be tighter die-cut ( ±0.2mm) than necklaces.

- Repeatability in assembling- Earring boxes require symmetrical gluing; necklaces require singular channel depth.

- Stability in production batches — In-house offset printing and finishing thru scale color match.

Designs that do not take into account the reality of manufacturing tend to fail miserably in quality as the volume of orders grows. At Crown Win, we make these details fine-tuned all the way to bulk production since we have in-house full control.

Common Design Mistakes Across Jewelry Packaging

A number of problems that are recurrent when the design of the package is not corresponding to the jewelry type is as follows:

- Inserting the same inserts in other products → results to poor fitting and movement.

- Putting the emphasis on visual symmetry instead of structuring support → Beauty when empty, utility when used

- Disregarding the behavior of jewelry during shipping → The outcomes will be scratches or misalignment.

- Underestimating time to wear inserts out of use distributed on heavy rings Foam wears out less on heavy rings.

To prevent these errors, design and manufacturing perspectives need to work closely at the earliest stage of work – and this is what we underline in all our projects.

Conclusion — Jewelry Packaging Design Should Follow the Product

The best approach to designing a jewelry box begins with the knowledge about the jewelry itself. Rings must be miniature, necklaces must be long, kept, and must be anti-tangled, and earrings must be symmetrically secured.

Brands that match packaging design with jewelry-specific needs have a greater opportunity to provide quality, reliable experiences that can be scaled across collections and markets in a smooth way. It is not only about protection but an affirmation of your brand with quality every time you unbox.

Are you going to talk jewelry specific packaging that is just as good as your jewelry pieces are? Get in touch – we would be happy to assist in making your idea a reality.