Meta Description: Learn all about homemade box templates, including gift boxes develop a dieline or a design pro program. Our guide will teach you how to design marvelous packaging that promotes your brand and ensures safe packaging of your items.

The dielines or custom box templates form the basis of the superior design of packages. On these flat templates, three dimensional boxes are created, which provide protection to the products as well as increasing brand recognition. To make memorable packaging with customizable dimensions , whether you are launching a new packaging or a new product, you need to know about custom box templates.

What Are Custom Box Templates and Why They Matter

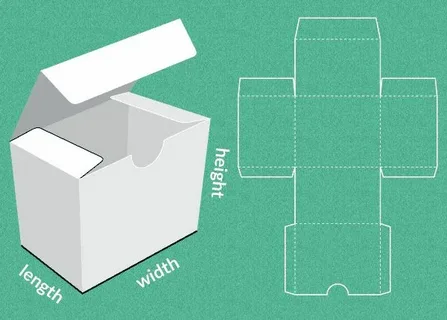

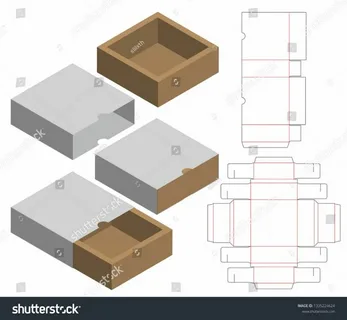

Custom box templates are two dimensional patterns that indicate the precise areas of cut, fold and glue materials that will work together to make a three dimensional box. Artwork templates can be used to create custom packaging content properly and they can be downloaded as pdf, free and fee using the design marketplaces, packaging forums, and software platforms on the internet. The custom templates enable you to design a packaging that fits your product dimensions and trademark perfectly unlike the standard boxes.

Custom box templates are not only useful in terms of functionality. They become the starting point of brand story telling, experience with clients, product safety, and overall convenience. Any effective product launch starts with a layout that is professionally done keeping in mind the pleasure of it as well as its functional ability.

Essential Components of Professional Box Templates

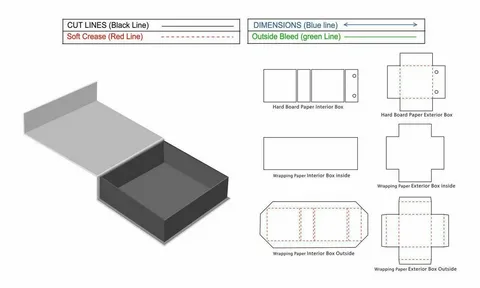

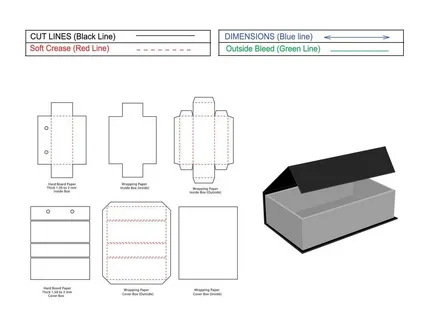

A number of very important features are used in professional custom box templates to make sure it is built in a manner that is proper and also appealing. Cut lines, fold lines and glue areas are the most basic elements for cake packaging . Cut lines denote the sides where the box material is to be trimmed and the fold line define the parts that should be creased. Crosshatching is usually used to mark glue zones in which adhesive is to be used in assembly.

Also, professional templates have safety spaces, bleeds and registration points. Safety margins apply so that critical design part is not later chopped during production for bottles , and bleed areas apply to have the graphics extend past the cut line so that when images are cut there are no white borders. Registration marks are used allow different color layers to be aligned during the printing process to result in a crisp and professional result.

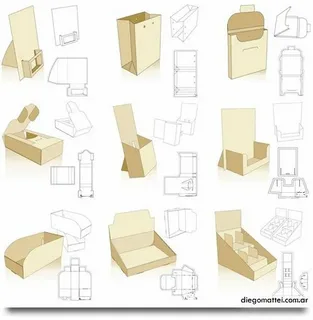

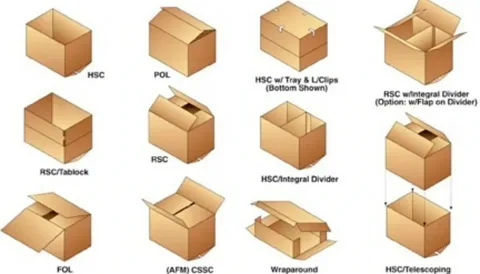

Different Types of Custom Box Templates

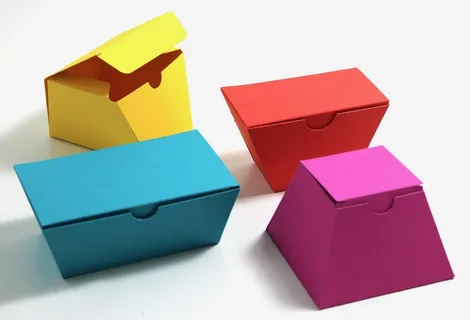

Custom box templates world is full of options to cater different products and brands requirements. Tuck end boxes, including cereal boxes, are the most common ones that have been used on retail products with the flaps tucking into the boxes without any form of glue being used. Such templates are fantastic in cosmetics, electronics, food, and even applicable for paper bags.

The mailer boxes are very popular in the e-commerce business whose aim is to deliver products directly to their customers. The functions within such templates such as easy open tabs and safe closing features is to secure products on transit and at the same time provide the thrill of opening an exciting package.

Set-up boxes also known as rigid boxes employ more intricate templates that generate high-looking packages on expensive products. These templates involve exact measurements, and usually have individual pieces showing box base and lid that form a high tech presentation adding to perceived value.

Free vs. Paid Custom Box Template Resources

Both the free and paid ones have their own benefits in the template marketplace. Free templates serve as an ideal starting point of small businesses and entrepreneurs in the process of testing new products with just a few clicks. Sites such as TemplateM aker and Pacdora, feature free custom-size templates, which are downloadable on a moment-to-moment basis and are thereby perfect in small-run and rapid prototyping applications.

The more advanced service, technical contact, and commercial rights to use are usually available in paid templates. High-end marketplaces such as Creative Market and Envato Elements offer professionally-designed templates crafted by a designer with step-by-step instructions and an option of selecting whether to have code or no code. It is usually in form of resources whose files can be readily edited and changed according to the size of the product.

Professional Design Software for Custom Box Templates

Adobe illustrator is still the software of choice in the creation of custom box templates with tight and accurate tools being vector-based. Professional packaging design can be done better with the software since it has a comprehensive collection of drawing tools, measurement capabilities, and managing the layers in one file . Nevertheless, a sharp learning curve may be needed by the novices.

Industry-specific softwares, such as Esko Studio and ArtiosCAD are specialized packaging software that have specific tools to produce box templates. This software has high features, which include 3D visualization, png support structural analysis, and svg manufacturing optimization and which simplify the design to manufacturing process.

Among other, more intuitive tools aimed at high-quality results, but simpler to use, there is Boxshot and Canva. Such sites usually come with pre-made templates, drag-and-drop options, and the ability to save your work as a file that allows the lay person to produce custom boxes without needing to learn any design skills.

DIY Box Template Creation: Step-by-Step Process

A scrupulous planning is a must in design of custom box templates and they need to be done carefully. Begin by taking the specifications of your product properly including the length, width, and height. Provide a space of clearance to make sure that the product fits well but is not overloose or overtight.

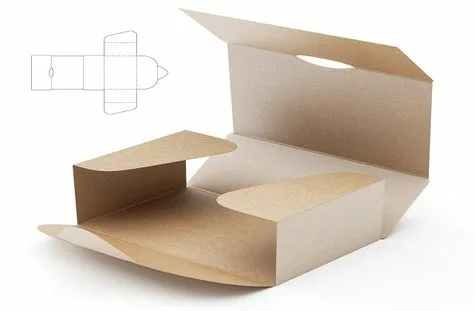

Second, ascertain the box style that would be most appropriate to your product and brand needs. Such aspects as the method of opening, storing and shipping should be considered. Draw your plans on a piece of paper with all panels, flaps and tabs that are necessary to have your construction properly built.

Scan your drawing into the computer so that you can use your software. Make proper measurements of every panel, fold lines should be at right position and gluing tabs should be of size. Put bleed marks on any printed graphics and test your template by making a paper prototype before finalising the design.

Advanced Template Customization Techniques

Templates can be modified using advanced customization to become one of a kind packaging experience. You can also include die-cut windows where your product will be displayed, but on the same hand, it will be protected. These characteristics demand careful planning of structure to make it look good.

Embossing and debossing is used to add tactile elements, which give a perceived value increase. Such effects necessitate special considerations of the templates such as additional calculations of the material thickness and adjustments of the folding lines to allow raised or depressed surfaces.

Easy open and perforated tear strip enhance security and the user experience. Such components must be kindly placed and tested in order to make them operate without reducing the structure of the box.

Material Selection and Template Adaptation

Various materials involve particular alterations in templates to provide the best outcomes. The templates made with corrugated cardboard require more space in the glue taps, respecting the width, and strengthening of folding lines to enhance the use of material grain to a specific thickness. Folding the fluting orientation influences the folding of the box and ought to be taken into account when creating the templates.

Templates made of solid paperboard can be more complex in design and closer on tolerances since the uniform thickness of the material and its smooth surface allow more detailing. These templates have the ability to enable more elaborate patterns of die-cutting and scoring that produces superior packaging experiences.

Kraft papers, labor cardboard, and special coated stocks each possess a distinct set of properties which call to template design. Knowing these attributes makes certain that your tailor-made template will do just as much during manufacturing and application.

Digital Tools and Online Template Generators

Online software has also transformed the design of custom box templates to such an extent that every person can use their designs on a professional level. Such platforms as the template maker of Pacdora give an opportunity to choose appropriate t

Such digital tools usually have real time 3D rendering options, so that you get to visualize how your template will appear as a complete box. In many platforms even there is a feature to provide cost estimation so that you can know the implications of manufacturing a particular design before settling with it.

Collaboration through cloud will allow teams to collaborate in creating template designs with everyone providing comments and updates in real-time. This benefit is especially useful to the companies that have remote workforces or collaborate with external service providers in designing.

Brand Integration and Visual Design Elements

The effective custom box templates are those that do not clash with brand elements but include them in a comfortable way that does not render the functions they perform inefficient. The use of color schemes is advised to be in tandem with your brand rules but have to take into consideration the restrictions in printing and the effects of the same in cost implications. Spot colors have the capability of producing dramatic effects however they can be costly in production.

The designers should pay close attention to the typography selection as it has a varied influence. Make sure that the text elements are well-sized and placed so they can be readable once folded and assembled. Pay attention to the text orientation at various panels of the boxes and the same hierarchy at the design.

The part of the logo location needs to be taken critically in mind which should be in consideration of exposure and security. Find a place that your logo will be well seen, yet not in a place where it could get ruined in the shipping or handling. Having several logo placements allows raising the awareness of a brand without confusing the design.

Testing and Prototyping Your Custom Templates

In order to scale into mass production, testing is important. Make physical models with your specifications of template and ideal materials. Making this process reveals possible problems of fit, purpose and assembly which may not otherwise be evident in a digital preview.

Assemble them to see whether the fold lines are in the correct position and the glue tabs have sufficient adhesiveness. Assess the structural durability by placing prototypes under real-world dictates such as stacking, material-testing transportation simulation and the opening and closing of the box.

User testing is a good way to get the insights about the customer experience. See how people treat your packaging, including troubles when opening it, withdrawing the product, or discarding. The response can be used to rework templates that will enhance satisfaction.

Production Considerations and Manufacturing Requirements

Knowing the parameters and requirements of the manufacture is important to successful implementation of custom box template. The various methods of production vary w.r.t. tolerance and limitations and these tolerances and limitations will have to be reflected in your template design. Die-cutting operations need to have clear cutting lines and sufficient material clearance of intricate shapes.

The process of registration is important especially when the templates are of many colors or have detailed drawings. Be sure that there are correct registration marks on your template and that it has taken into consideration the possible color shift in the printing process. Such precision eliminates reprints and delays at a high cost.

Tab sizes, the position of a fold line, the thickness of the material are special requirements of the folding and gluing equipment. Work with your manufacturer as early into the designing process as possible and make sure your template is optimized to work with THEIR equipment and procedures.

Cost Optimization Strategies for Custom Templates

Wise decisions in template designing are the key to effective cost management. It is possible to match and integrate some of the dimensions used in several products to streamline setup costs and wastes. It will be worthwhile to consider template families which can have common factors though be specific with the product.

Optimizing the use of materials may make a vital difference to costs. Design patterns with rotation so as to get the maximum boxes out of commodity size sheets. This method reduces wastage and would save massive costs when ordering large volumes of production.

Printing cost management is all about striking a compromise between the artistic effect and worries about cash. Utilization of spot color effectively, reduction of graphics, and cost-effectiveness in color arrangement are potent in sustaining the design quality within the management of cost. Look at the differences between various printing techniques in terms of costs and quality.

Future Trends in Custom Box gift boxes Template Design

The packaging industry is an evolving system, where sustainability issues have imposed major changes in the methods of design templates. The minimalism that decreases the amount of material used to produce products with functional purpose is becoming popular. Such templates sometimes use a simple yet ingenious folding methodology which does not require glue or tape.

The integration of smart packaging is spreading further and further, the types of packaging templates are formed to the possibility of adding QR codes, NFC tags, and other digital solutions. Such features must be placed safely and have to be logged, carefully placed and safely guarded so that the same may continue to work throughout the life of the product.

The possibilities of personalization are increasing, and the use of digital printing helps them personalize single boxes with low-cost. The variable bed printing requires that the template designs can be printed at varying amounts of data, taking into account the length, width, and height of the boxes, while still keeping the structural integrity and appeal.

Conclusion

Custom box templates are the ideal merge of functionality, creativity, and brand identity, serving as essential packaging templates for various products. The design and production of the perfect template packaging of the products can benefit businesses and help them not only provide maximum protection to their goods but also to make a greater and positive impression on the customers and to make their brands stand out settings. The dividends of efforts that have gone behind procurement of quality custom box templates are evident in the form of hundreds of better customer satisfaction, better brand loyalty, and better market positioning.