Corrugated Cardboard

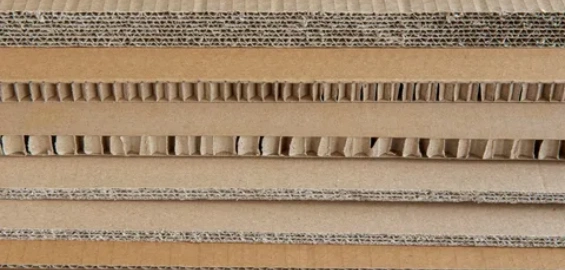

Corrugated paperboard, also known as corrugated fiberboard or corrugated cardboard, is a type of packaging material made up of flat outer liner layers and a fluted inner layer. The slight variation among these terms often depends on the materials used—whether paper or fiber-based—to enhance structural strength and durability.

In packaging terminology, “cardboard” serves as a broad term that includes several types of heavy paperboard. Among these, corrugated fiberboard stands out for its unique construction: a fluted (wavy) layer sandwiched between two flat linerboards. This corrugated structure is formed through a specialized corrugating process that imparts rigidity and impact resistance, making it an excellent choice for shipping, retail packaging, and long-term storage.

Thickness of Corrugated Cardboard

The thickness of corrugated material primarily depends on its two key components: the fluted layer and the linerboards.

Flutes

Flute types determine the board’s caliper (thickness in inches). Each type has its own distinct thickness and varies in flute height and frequency (the spacing between the waves).

A Flute

This classic flute style is well-known for its superior cushioning performance and strong stacking capability. It is mainly used for shipping and packaging delicate items due to its strength, featuring 36 flutes per foot and a height of ¼ inch.

B Flute

Type B offers distinct properties, such as outstanding resistance to crushing and denting. It adds an extra layer of protection and works well as a divider for heavier items. With a height of ⅛ inch and 49 flutes per foot, it provides greater packaging stability compared to A flute.

C Flute

Type C is another strong choice for packaging and shipping, featuring a thickness of 11/64 inch and 39 flutes per foot. It is widely favored for its durability under handling and transport conditions. Additionally, it offers high resistance to compression and crushing, along with a smooth surface ideal for printing and labeling.

E Flute

Type E offers enhanced resistance to crushing and bending, making it a more efficient option. Its relatively flat surface ensures smooth, high-quality printing. Lightweight and thin, E flute boards are excellent space-savers and are widely recognized as a superior alternative to traditional paperboards. They are commonly used for packaging delicate items such as ceramics, cosmetics, and glassware. With a thickness just over 1/16 inch and 90 flutes per foot, E type provides both protection and printability.

F Flute

F flute is specifically designed for packaging consumer goods, especially for retail applications. As the thinnest option among all flute types, it measures just 1/32” in thickness and features 125 flutes per foot, providing enhanced rigidity. Its lightweight construction uses less fiber, making it a cost-effective and efficient choice for items like point-of-purchase displays, jewelry, cosmetics, shoe boxes, and even clamshell-style food packaging.

Each flute type offers distinct advantages, including excellent compression strength, superior stacking capability, high crush resistance, and strong flexural rigidity.

Liner Boards

The strength and durability of corrugated boards depend not only on the flutes but also on the outer layers, known as flat liner boards. These liners play a crucial role in the overall performance of the material and are available in several types:

Kraft Liners – Categorized by color and fiber content, including:

Brown Kraft Liners

White Top Liners

Mottled White Kraft Liners

Bleached Kraft Liners

Birch-Faced Kraft Liners

Test Liners

Chip Liners

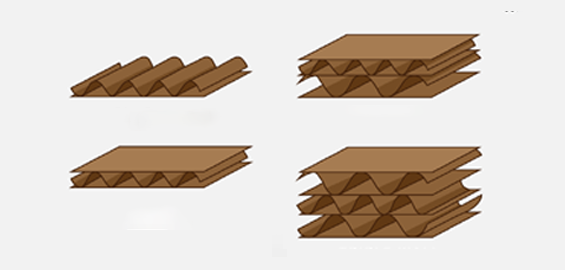

Types of Corrugated Cardboard

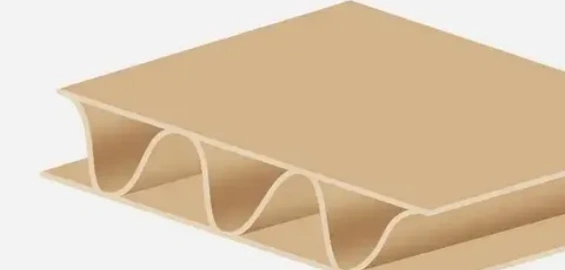

Single face

- It consists of two layers: one fluted medium and one liner.

- Provides additional cushioning and protection.

- Layer arrangement: fluting on the inside, liner on the outside.

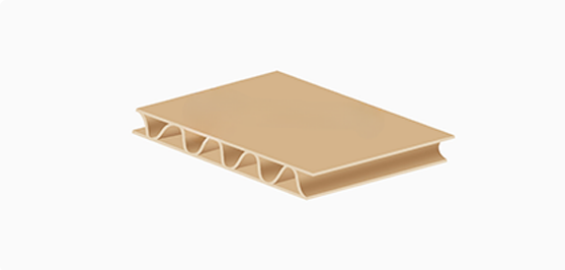

Single-Wall

- This is the most widely used form of corrugated cardboard.

- It features two outer liners with a fluted layer sandwiched in between.

- The layer sequence is: liner – fluting – liner.

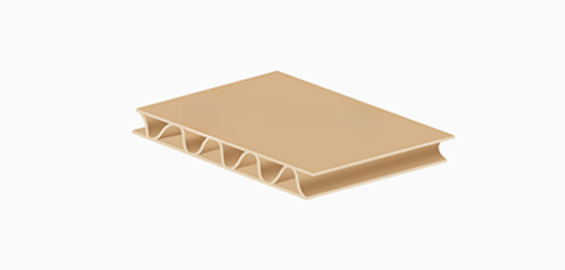

Double-Wall

- This type is strong enough to serve as a substitute for wooden crates.

- It consists of three fluted layers and four liner layers, providing excellent durability.

- The sequence of layers is: liner – fluting – liner – fluting – liner – fluting – liner.

Double-Wall

Customer support is available 24/7 to assist you with any info, queries, order tracking & more.

Characteristics and Uses

Depending on the type and your preferences, this robust material can be used for a variety ofpackaging purposes, like:

Strength and Durability

Corrugated fiberboard is renowned for its durability and is ideal for safeguarding and transporting a variety of products.

Cushioning

The air pockets within the corrugated layers deliver a cushioning effect, helping to protect items from shocks and impacts during transit.

Versatility

Fiberboards offer easy customization in terms of size, shape, and printing, making them highly versatile for a wide range of packaging needs.

Sustainability

Many corrugated fiberboards are produced using recycled materials such as old corrugated containers and double-lined kraft paperboards, supporting sustainability initiatives within the packaging industry.

Cost-Effective

Corrugated fiberboard is widely favored around the globe due to its cost-effectiveness and lightweight nature, making it a highly demanded packaging material compared to other alternatives.