Introduction

Custom jewelry packaging is often conceived on good intentions but wrong assumptions. A lot of package failures are not due to lack of creativity, but rather because we did not consider the impact of the structure, inserts, finishing and consistency of in the manufacture on actual performance.

Nonetheless, knowledge of these typical errors can assist brands to avoid both expensive redesigns and poor quality and brand-image damages. What is more important is that it enables the packaging decisions to succeed in promoting long term growth as opposed to short term visual attractiveness.

Mistake #1: Treating Jewelry Packaging as a Visual-Only Decision

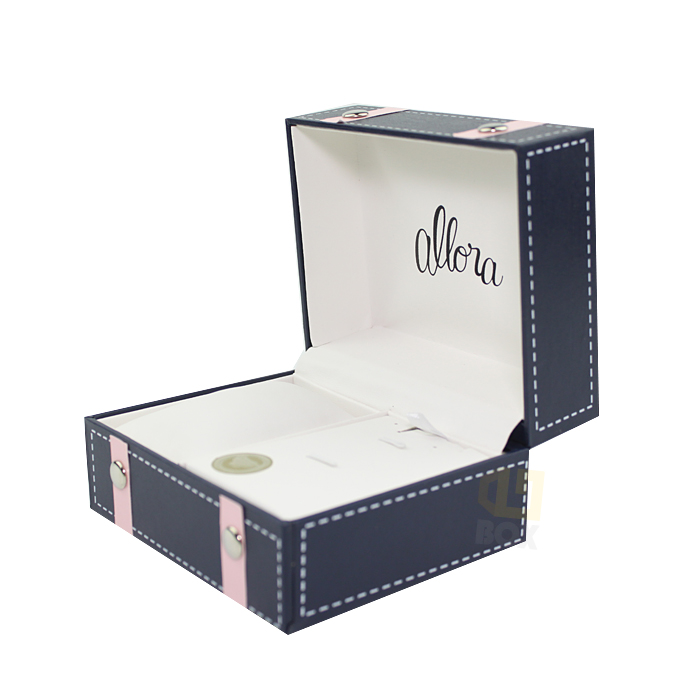

The biggest error that we can observe is the biased judgment of packaging based on the sight. Although the appearance of the products is crucial in that wow-factor unboxing experience, the packaging of the jewelry should be structural throughout the shipping and storage processes and the opening and closing of this package many times by the customers.

In cases where the visual design is the leading and the structure is neglected:

- Boxes may be constrained in the warehouse or during the transportation process.

- Inserts could not be good in holding pieces and may create scratches or flow.

- The first experience becomes degraded soon: Lids sink, magnets become weak or edges crank.

The fix? Visual ambition and functional engineering should be synchronized at the concept stage. In our factory we never finalize looks before we discuss the structure satisfactorily making sure the box will work in actual logistics.

Mistake #2: Using Generic Box Structures for Different Jewelry Types

The necklaces, the full sets, the earrings, the rings, and the bracelets will react in diverse ways within a box. The use of a single generic structure within product lines is a frequent cause of protection and presentation tradeoffs.

The breakdown of risks is as follows:

- Rings — Rotation, misalignment of over-sized cavities or shallow ones.

- Necklaces — Chain pressure damage, or the pendulum shifting.

- Earrings — Symmetry disaster when posts are not very firmly held.

- Sets an Imbalanced presentation where pieces conflict over space.

Even to avoid this mistake, the box structure and the design of the insert should be matched with the nature of the jewelry. As an example, we serve rigid boxes, which are custom made to suit the depths of each type and magnetic close-ups to prevent movement without affecting the luxury display.

Mistake #3: Underestimating the Importance of Insert Engineering

Inserts can be considered as being substitutable or being added afterwards. The result is the loose fits, compression due to time, inconsistent presentation or even reaction of materials with laborable constituents.

Ordinary insert-related complications are:

- Big holes in which the jewelry rattles.

- Lack of retention power particularly in heavy items.

- After shipping or protracted storage (some foams permanently compress) material deformation occurs.

Design insert ought to be part of the essence of packaging engineering, as opposed to an appendage. We provide the choices of precision-cut EVA foam, molded pulp, sponge, or paperboard—each chosen based on the jewelry’s weight, shape, and sensitivity. Testing retention under simulated drops and vibration is key to getting it right.

Mistake #4: Overusing Finishing Techniques to Create “Luxury”

The other common trap is that of overlays foil stamping, embossing, debossing, spot UV, or one or several laminates with an effort to create a feeling of premium- especially where the base structure or materials are precarious.

Most of the time, the excessive finishing leads to:

- During assembly, some problem with alignment is present.

- Increased production defect.

- Loss of repeatability on order scaling up.

The real luxury packaging is not emulated by bombast and imprecision. We would emphasize clean, consistent application such as the use of soft-touch lamination to create a velvety feel or delicate accents of foils but keep production consistent between batches.

Mistake #5: Evaluating Packaging Based Only on Samples

Samples can be ideal, with perfect lighting, one-time construction and no transportation stress. They do not necessarily display the performance of packaging at a hundred or even thousands of units.

Problems that occur following scaling are:

- Differences in the thickness of the material or gray board density.

- Piecing incongruities in manual/semi-automated processes.

- Completion of misalignment due to batch to batch color shift.

Brands seeking professional jewelry packaging solutions would be well off checking the suppliers on the basis of the process control and the quality systems rather than the samples. Search internal ability, multi-level QC, and certifications such as ISO, BSCI, and SGS to obtain uniformity on one scale.

Mistake #6: Ignoring Long-Term Consistency and Reorders

Jewelry package is not more likely to be a single exercise. The brands repackage identical designs in different seasons with different collections and across different markets- but many fail to take note of repeatability.

Non-consistency in the long term leads to:

- Perceptible variation among batches (change in color, shifts in texture, etc).

- Poor brand recognition in the long run.

- Higher quality complaints by the customers who are loyal.

Previous packaging ought to be done and assessed considering repeatability at early stages. The process of our factory work that is controlled by us including inspection of raw materials, to the final assembly assists in maintaining the exact specifications in terms of specification on an order per order basis.

How Brands Can Avoid These Packaging Mistakes

These pitfalls may not be avoided without a systematic procedure and not by guess:

- Begin with product behavior and actual world usage case (shipping, in-store display, interaction with customers)

- Pairs structure, inserts and finishing with brand positioning and price point.

- Assess manufacturing capacity and quality control mechanisms at early stage- request auditing of process or visits to factories.

- Drop tests Prototypes are tested under realistic logistics conditions (drop, vibration, humidity).

- Design repeat production, not the first time production– scale in tolerances and specifications.

It is a risk-averse technique and minimizes the redesign costs, along with sustainable packaging performance, which increases as your brand expands.

Conclusion — Good Packaging Avoids Problems Before They Appear

The majority of failures which happen during custom jewelry packaging may be avoided. They are due to ignoring structural reality, introducing performance and completeness training discipline and production consistency.

Brands that treat packaging as an engineered system as opposed to a decorative accessory are in a lesser position to prevent costly errors, safeguard their products, and provide equalized, superior experiences that build brand trust, over an extended duration.

Irrespective of whether you are read to go outside the rut of poor structures and create a packaging that really delivers, we can assist you with an all-in-house design-to-deliver services.