Introduction

The conventional method of coffee packaging has been cost-effective and product protection, which has been done at the expense of the environment. The market today requires a new strategy to be considered, which includes the brands that have to balance in the delicate environment between the costs of materials, the influence on the environment, and the satisfaction of the consumers.

This step-by-step approach looks at the viable methods of making sure that cost efficient coffee packaging does not affect the sustainability component and helps the coffee labels make the correct commitment, which is good both to the bottom line and the world.

Why Sustainability in Coffee Packaging Matters

Environmental Impact and Consumer Expectations

Millions of tons of packaging waste are produced in the coffee industry annually, and much of it ends up in landfills or contaminates the oceans. The traditional multi-layer packaging is effective in preserving freshness, but it has immense disposal issues as it cannot be recycled; studies have shown that 73 percent of consumers globally are willing to pay extra to purchase environmentally friendly goods. This has transformed the consumerism style such that not only is sustainable packaging an environmentally mandated requirement, but also a competitive need.

Market Trends and Competitive Landscape

Even the most popular coffee goods are already moving in the direction of more environmentally friendly packaging. The industry is going through a paradigm shift in regards to packaging through the use of compostable coffee pods and recyclable valve bags. The brands that fail to respond to this threat are losing market share to the competitors who are more eco-conscious.

Regulatory Pressures and Certifications

The governments all over the world are implementing stricter packaging policies, including single-use plastic bans and the extended producer responsibility laws. In many areas, some of the certification programs like Forest Stewardship Council (FSC) and Biodegradable Products Institute (BPI) are necessary before they can gain market access.

Brand Value and Storytelling

Sustainable packaging already becomes the part of brand narration that can allow coffee companies to address consumers on shared values. When smartly applied sustainable packaging initiatives can result in brand loyalty and high pricing.

Understanding the True Cost: Beyond Material Price

Lifecycle Cost Analysis

In the comparison of packaging, the lifecycle of the packaging must be taken into account instead of looking at the end-of-life material cost. This includes:

- Material and production costs: Of the raw material and manufacturing expense.

- Costs of transportation: Smaller, lighter packaging will save you shipping money.

- Storage needs: An effective design of the package can minimize the warehouse space.

- End-of-life expenses: Disposing, recycling, or composting facilities.

Hidden Costs of Traditional Packaging

The conventional packing can seem to be economical at first sight, yet the expenses can be hidden:

- Spoiling of products: There may be poor coffee spoilage and returns due to poor barrier properties.

- Brand reputation risk: Environmental backlash has the potential to have an effect on long-term brand value.

- Environmental regulations: Fines may be imposed in case of non-adherence to environmental regulations.

- Lost opportunities: Failure to capture markets with high sustainability standards.

Long-term Benefits of Sustainable Investment

Long-term pay-off on investing in sustainable packaging may be long-term:

- Customer loyalty: The environmentalists tend to become brand followers.

- Operation efficiencies: The optimization of packaging can decrease labor expenses.

- Economies of scale: With sustainable materials going mainstream, the costs are reduced.

- Risk mitigation: Future-proofing the evolving regulations and consumer preferences.

Comparing Material Options

Mono-Material Plastics

Pros: Resistant to obstacles well, lightweight, and cheap when it is needed in quantity.

Negatives: Not very recyclable, petroleum-based, bad perception by consumers.

Cost: It tends to be 10-20 per cent cheaper than long-term sustainable products.

Ideal applications: It is commonly used in large volume productions where recycling facilities are present.

Bioplastics and Compostable Materials

Advantages: Carries less negative impact to the environment, new brand positioning, biodegradable.

Disadvantages: More costly than standard plastics, limited industrial composting plants, and limits performance

Uses: Premium brands on the market and aimed at environmentally conscious consumers.

Paper-Based Solutions

Pros: Recyclable, renewable resource, high printability.

Cons: Limited barrier properties, may require additional linings, and moisture sensitivity.

Pricing: Competitive price, especially for easy designs, may be utilized in short-term storage or highly turned-over retail outlets.

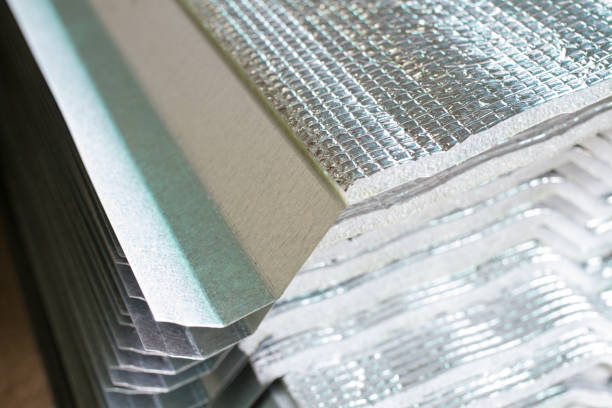

Aluminum and Foil Linings

Advantages: Better barrier properties, can be recycled indefinitely, high appearance.

Disadvantages: More expensive materials, it is energetically demanding to produce, fewer design options, fits most products that require an extended shelf life.

Recycled Materials

Advantages: Lower environmental footprint, price reduction on raw materials, support of the circular economy.

Disadvantages: Quality differences, low availability, and possible contamination concerns.

Cost: Generally, 5-15 percent cheaper than virgin materials. Best brands with high sustainability pledges and quality management systems.

Emerging Alternatives

New materials are also coming to the market, such as mushroom-based packets and seaweed films, although at the moment these are priced at the higher end and are scarce.

Design and Functionality Decisions

Optimizing Barrier Properties

The trick to affordable, sustainable packaging is to avoid over-engineering, give the packaging sufficient barrier protection. Consider:

- Oxygen transmission rates: Compare product shelf life requirements to match barrier requirements.

- Protection against moisture: Appropriate amounts are used depending on the conditions of storage.

- Light protection: Assess the need on the basis of the opaqueness of the packaging and the environment of storage.

Size and Weight Optimization

A smaller size and weight of the packaging have several advantages:

- Reduced material costs: Decreased use of material leads to cost reduction.

- Lower expenses in shipping: Light packages are cheaper to transport.

- Less carbon footprint: Less emissions in transportation.

- Enhanced shelf efficiencies: Enhanced space use in retailing settings.

Smart Design Features

- Resealable caps: Make the product last longer without extra packaging.

- Modular designs: Standardized production runs are possible.

- Minimalist designs: Minimize the cost of printing and finishing, and attract consumers in the contemporary world.

Cost-Saving Strategies

Strategic Supplier Partnerships

Creating a good rapport with packaging suppliers may save a lot of costs:

- Volume commitments: Get better prices with guaranteed volumes.

- Local sourcing: Save on transportation and benefit local economies.

- Mutual growth: Find win-win solutions.

Standardization and Modularity

- Common sizes: Standard sizes are used in product lines to boost volumes.

- Common tooling: Minimise the setup cost through common dies and moulds.

- Flexible printing: Use templates that can be used to print a variety of products.

Production Efficiency

- Batch optimization: Design production runs to optimize production.

- Seasonal planning: Match packaging orders with the high production times.

- Inventory control: Trade off between balance carrying costs and volume pricing advantages.

Incentives and Certifications

- Government grants: Research eligible sustainability incentives.

- Tax breaks: Learn about environmental deductions.

- Certification fees: Invest in certifications with better margins.

Case Studies and Real-World Examples

Premium Roaster Transformation

A small coffee house roaster managed to switch to compostable packages, replacing the traditional plastic bags with.

- Collaborating with a local compostable movie producer.

- Installing a customer education scheme on appropriate disposal.

- Replacing all packaging with sustainable ones in 18 months.

- Outcome: 25 percent rate of customer retention and 15 percent premium rate.

Large-Scale Cost Optimization

A distributor of coffee in the region was able to cut the cost of packaging by 18 percent and enhance the sustainability by:

- Standardizing three sizes of bags on all products.

- Bargaining volume rates on recycled paper bags.

- The adoption of a take-back initiative on used wrapping.

- Reducing packaging design to save 12 percent of materials.

Communicating Sustainability to Customers

Transparency and Education

Avoid confusion on packaging options, create consumer confidence:

- Material disclosure: Place packaging composition and disposal instructions on clear labels.

- Sustainability measures: Report specifics of environmental payoff.

- Progress reports: Let people know about progress and future objectives.

Certification and Labeling

- Third-party certifications: Use symbols such as FSC, BPI, or Cradle to Cradle that are recognized.

- Clear disposal guidelines: Derive clear guidelines for local waste systems.

- QR codes: Take to the full sustainability and disposal instructions.

Avoiding Greenwashing

Make sure that all sustainability claims are:

- Verifiable: A third-party testing and certification.

- Specific: Do not use non-specific words such as, eco-friendly.

- Complete: Recognize areas of excellence and areas of improvement.

Common Challenges and Solutions

Higher Upfront Costs

Challenge: Sustainable materials are sometimes more expensive in the short term.

Limited Material Availability

Challenge: Sustainable alternatives can be the lengthening of lead times or a smaller number of suppliers

Solution: Build relationships with a number of suppliers, inventory planning.

Consumer Education Gaps

Challenge: Consumers do not know how to dispose of it correctly

Solution: Invest in labeling, educational material, and collaboration with communities.

Performance Concerns

Issue: The dilemma between protection and sustainability

Solution: Intensive testing, incremental changes, and contingency.

Actionable Checklist for Getting Started

Immediate Steps (Week 1-2)

- Check the existing packaging expenses and environmental footprint.

- Local recycling and compost research.

- Determine sustainability priorities on brand values.

- Request quotes with 3-5 sustainable/green packaging suppliers.

Short-term Implementation (Month 1-3)

- Do consumer surveys regarding packaging choice.

- Test alternative lines of products as per sustainability.

- Establish supplier connections and bargain.

- Produce customer education documents.

Medium-term Goals (Month 3-6)

- Introducing a pilot program for a few products.

- Measure performance indicators (cost, customer response, quality of products)

- Optimize disposal guidelines and communication to the consumers.

- Plan the scaling strategy of successful pilots.

Long-term Vision (6+ months)

- Implement winning solutions in product lines.

- Introduction of take-back or circular economy initiatives.

- Get applicable sustainability certifications.

- Share stories of success and learning.

Key Metrics to Monitor

- Cost per unit: Monitor packaging cost progress over time.

- Customer satisfaction: Check on new packaging feedback.

- Environmental impact: Measure waste reduction and carbon footprint.

- Market response: Monitor sales performance and brand perception.

Conclusion

The aim of attaining cost-effective coffee packaging without any need to compromise on sustainability promise is not only possible, but it is also becoming a prerequisite to business success. The trick lies in the fact that companies should think in terms of the big picture, which involves lifecycle costs, being innovative, and focusing on consumer education to be strategic to drive both the environmental impact and the company upwards.

Through the assistance of small pilots, good supplier relations, and open communication with the customers, the brands will have the chance to make the process of moving to more sustainable packages successful. You can be a small roaster and want to make your brand a standout or a big distributor and need to simplify the operations; either way, the tips provided in this guide will serve as a roadmap to the achievement of a packaging solution that is easy on the consumers, the environment, and also on the business.

It is important to keep in mind that sustainable packaging is an evolutionary process, and not a revolutionary one. Begin with a small step, evaluate the effects, absorb the lessons, and proceed with the achievements. Your customers, your business, and the planet will be grateful of you for taking this great step forward.