Introduction

Millions of packages are damaged every year because of a great omission in the thickness of the cardboard that is chosen. It may be a damaged, opened box of cosmetics that ruins a customer experience when unpacking their products or a damaged shipping box that costs thousands of dollars in lost merchandise. The cardboard thickness is a crucial issue in product protection and business success.

The misunderstanding of this fundamental packaging type is the most prevalent business problem. The boxes are dropped out of the stacking pressure, the goods are easily broken during transportation, companies are either paying too much due to unnecessarily thick wrapping or saving too little and having to pay a lot due to claims of damaged goods.

With this comprehensive resource guide, you will understand how to measure cardboard thickness, the different units of measurement, and most importantly, how to be able to choose the best cardboard thickness based on specific needs, that is, depending on your packaging needs. By this time, you will be informed enough to make prudent decisions that will protect your products at minimum cost and in a sustainable manner.

What is “Cardboard Thickness”?

Cardboard thickness is described as the measurement of the thickness of a piece of packaging material, but it is more complicated than measuring it with a ruler. The thickness refers to the total assembly of the board, including numerous layers of paper and air between them in corrugated materials.

One should know the difference between various types of boards. Cardboard is also a general term used to denote the thicker single-layered paperboard that is employed in the packaging of products such as cereal boxes. Paperboard is generally made much thinner, and it can be used to pack items such as cosmetic boxes or pharmaceutical cartons. Corrugated board is the most used type of shipping material that is made of a fluted (wavy) inner layer, which is sandwiched between plain outer coverings to form better strength and cushioning.

Construct material construction remarkably influences the thickness and strength. In the corrugated board, the flutes (wave-like inner layer) serve to give structural integrity, but the weight is relatively low. The final thickness, strength, and performance of the board are determined by the liner materials (the flat outer layers) and the flute medium. A board may be 4mm thick; however, the strength could differ by huge amounts depending on the quality of material and flute layout.

Units & Measurement Methods for Thickness

To know the thickness of cardboard, it is better to learn the measurements of various units and methods that have different uses in the packaging industry.

The weight of the paper is measured in grams per square meter (GSM). Although GSM implies the density and the quality of a material, it does not exactly specify the thickness of a board. A paperboard of 250 GSM may be 0.3 mm, and this may depend on the density and makeup of the paper. The benefit of GSM lies in the fact that it is universal, but the disadvantage is that it fails to consider air penetrations in corrugated materials.

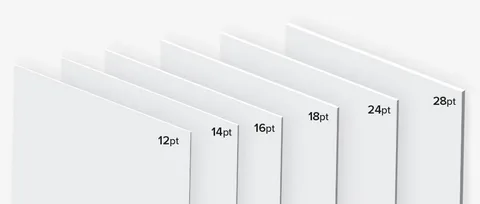

The North American system is mainly used, and the measure of thickness is in thousandths of an inch, shown as points (PT). An illustration of this is a 24 pt board, which is 0.024 inches thick. The measure is more straightforward than that of GSM because it can measure physical thickness, and this is simpler to comprehend and apply to practice.

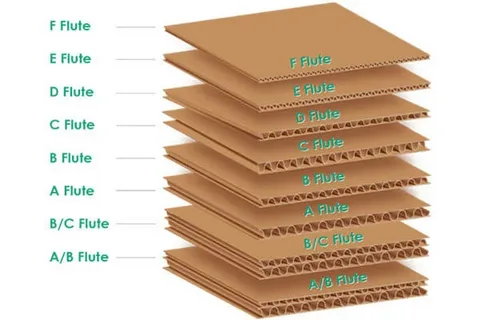

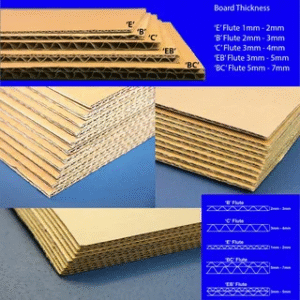

Types of flutes are essentially about corrugated materials, and they are identified by letters (A, B, C, E, F, etc.). The average height of each type of flute is as follows: A-flute is around 4.5-5 mm, B-flute is 2.5-3 mm, C-flute is 3.5-4 mm, E-flute is 1.5 mm, and F-flute is about 0.75 mm. These measurements influence cushioning and thickness.

There are numerous differences in the complexities of board construction. Single-wall corrugated contains only one layer of flutes with two liners that are normally 3-5 mm thick. There are two layers of flute and three liners, typically 6-7 mm, in a double-wall construction, and a triple wall may be 15 mm in thickness. Single-face corrugated has fluting on a single side and is normally utilized as a protective wrapping.

Thickness can be measured using a caliper or a micrometer to measure this physically. Regular rulers need to be avoided since they tend to squeeze the flutes and provide false measurements. Measure the points at a number of points on the board since they may change slightly because of manufacturing tolerances.

Common Cardboard Types & Their Typical Thicknesses

Different packages need different cardboard types, which vary in thickness and performance.

E-flute corrugated (1.5 mm thick) would be suitable in retail packaging, cosmetic boxes, and items that need an outstanding print. It is sleek in profile, giving it a high-end look and moderate protection. The key benefits are the high printability and low space usage, but it does not provide much cushioning on delicate objects.

F-flute corrugated (0.75 mm thick) is the thinnest corrugated material, ideal for packaging small items as well as where the amount of space is important. It offers low protection, but it has high-quality print and material efficiency.

B-flute corrugated (2.5-3 mm thick) is used in small to medium shipping boxes, food packages, and products that need medium protection. It has excellent stacking capacity, acceptable print quality, and low cost efficiency.

Shipping boxes typically use C-flute corrugated (3.5-4 mm thick), which is highly cushioning and stacking so as to provide excellent protection and strength. It is perfect for the general shipping process and medium-weight goods and offers good protection during transportation.

A-flute corrugated (4.5-5 mm thick) is used to offer maximum cushioning when building a single wall, when dealing with fragile goods, large boxes, or products that need a high level of edge crush strength. It is, however, less appropriate in high-quality printing and consumes more material.

The double-wall corrugated (6-7 mm thick) has the strength and protective quality for heavy products, long-distance delivery, and goods that have long storage requirements. It is very much more expensive but offers superior shelf life and load capacity.

Triple-wall corrugated (15 mm thick) is used as an alternative to wooden crates when dealing with very heavy products, industry, and international shipping, where maximum protection is needed. Although it is, of course, pricier than the alternatives of packaging that are likely to be more expensive.

How Thickness Impacts Other Factors

The cardboard thickness produces a ripple effect on various facets of the packaging performance and costs, and it is essential to comprehend the inter-relationships that exist between the two.

As the thickness increases, protection and durability increase, but are not always linear. Board thickness is generally a good indicator of edge crush strength, which is necessary in the stacking of the boxes in warehouses and trucks. They are also more puncture-resistant and have impact cushioning. Nevertheless, the design of the flute is frequently more important than bare thickness – even a single wall could be designed to be more effective in certain tasks than a poorly made double wall.

Thickness has a direct influence on the cost of shipping based on weight and dimensions. Heavy packaging increases the weight, which makes the process of shipping expensive, particularly when the matter is air freight, and every gram matters. Also, the greater the thickness of the walls, the lower the internal volume that would necessitate an increase in the outer dimensions to fit the same product, which has an impact on the dimensional weight pricing employed by most carriers.

The opportunities of printing and branding depend on the thickness and type of board. Smaller boards such as E-flute and F-flute have good print surfaces because of high-quality graphics and fine details. More cushy boards might not take the ink uniformly, which could impact the presentation of the brands. The smoothness of the board surface, which is mainly dictated by the way it is constructed, affects the cost and quality of printing.

The implication of sustainability with an increase in thickness is that more raw material is needed, resulting in more environmental impact in the process. Nonetheless, the denser boards tend to have a greater amount of recycled material and might avoid damage to the products, leading to waste. The trick lies in ensuring that the ideal thickness is determined, which is not too thick and still ensures that it covers the product.

How to Choose the Right Cardboard Thickness for Your Needs

The correct choice of cardboard thickness is dependent on several factors that are unique to your product and shipping needs.

Product fragility assessment. You should begin with product fragility analysis. Very delicate goods such as glassware or electronics are normally corrugated with either two walls or a thick single wall (5mm+). Fragile items such as books or small appliances are moderately strong and will fit with standard C-flute (3.5-4 mm). Permanently used products like clothing or non-breakable products may be able to use B-flute or E-flute.

Shipping distance and mode Mode and the distance of shipment are major factors that affect thickness requirements. Domestic delivery can use a lighter package, whereas international delivery requires a tougher one. Airfreight involves a balance between protection and weight, which usually favors a single wall rather than a double wall. Stack strength and durability are normally optimized with ground shipping.

Stacking and storage requirements. Edge crush strength requirements depend on the number of layers and storage requirements. Very high edge crush strength boards are needed to store products that are stacked high, such as those used in the process of storage. Storage time at the warehouse is also important—the more time it is going to be stored, the more the packaging should be considered thicker and tougher.

Budget constraints. There should be a balance of the budget on material costs and their possible damage costs. Divide the freight cost by the packaging and shipping price and the cost of the damage claim. A 20 percent increase in packaging costs will save a lot more in damage prevention.

Brand and appearance considerations. Brand and appearance will possibly need to work within a certain range of thickness. High-quality products tend to require heavier and denser packaging, which sends across quality. Retail packaging usually requires the best printability, and using either thinner corrugated or quality paperboard is preferred.

To use in practice, use the following rules: In case your product is not very heavy and is shipped locally, then use B-flute or C-flute (2.5-4mm). When dealing with delicate products that are being shipped abroad, either a double-wall corrugated (6-7mm) or heavy-duty single-wall (5mm+), along with the corresponding cushioning, should be used. In the case of heavy products more than 10kg, the construction of the walls is normally double-wall or triple-wall construction, whether fragile or not.

Conversion & Comparison Tables

The knowledge of the connections between various measurement systems will assist in making informed choices regarding packaging:

GSM to Thickness Approximations:

- 125-200 GSM paperboard: 0.15-0.3mm thickness

- 200-300 GSM paperboard: 0.3-0.5mm thickness

- 300-400 GSM paperboard: 0.5-0.7mm thickness

Flute Type Thickness Guide:

- F-flute: 0.75mm (good retail packaging)

- E-flute: 1.5mm (small shipping and premium retail)

- B-flute: 2.5-3mm (standard light shipping)

- C-flute: 3.5-4mm (shipping boxes most used)

- A-flute: 4.5-5mm (single wall cushioning) (maximum)

Comparison of the board construction: Single-wall corrugated is the most suitable board construction in terms of cost to protection location, with a thickness of between 0.755 mm. The strength of the double-wall construction is 40-60 percent stronger than the single wall, but it increases the material costs twice. Triple wall is a high-strength product that is mostly economical when it comes to very heavy or highly prized goods.

Edge Crush Strength vs. Thickness: Edge crush strength tends to be higher with the increase in board thickness, an important factor in stacking. A 3 mm C-flute usually provides 4-6 BCT (box compression test) per linear inch, and a 6 mm double-wall can give 8-12 BCT per linear inch, although these depend on paper quality and manufacturing.

Common Mistakes & Myths

There are also a number of myths regarding cardboard thickness that make it an ineffective choice of packaging that costs businesses money as well as the protection of the goods.

A popular misconception is that durability is not defined by GSM itself. The GSM paperboard may be high, which appears heavy, but does not have the structural integrity required to protect shipping. On the other hand, a GSM corrugated board of correct flute construction can be very good protection. GSM is a measure of the density of the paper and not the structural performance.

Another expensive error is always thinking that thinner is better. Unnecessarily specifying the thickness makes the materials more expensive, heavier, and less environmentally friendly. A 3 mm board has a tendency to perform better than a 6 mm board, which was poorly assembled at a much lesser cost.

Underestimating handling damage happens when business organizations are only concerned with the protection of the product at the expense of packaging durability when products encounter various handling operations. Packages may be fine after the first drop, but after being handled, stacked, and exposed to the environment many times during the supply chain, they fail.

The disregard of print requirements contributes to the dismal brand presentation. Premium cosmetics with the selection of thick corrugated may end up saving on costs of materials, but produce poor printing outcomes that will harm brand perception. The surface of the packaging should be up to the marketing standards.

Dryness is often taken care of. Wet cardboard becomes weak, and the thickness does not always ensure better protection against moisture. Raw thickness is not important in humid environments: board composition and any form of protective coating are.

Cost vs Benefit Analysis

Only by analyzing the short- and long-term costs of the entire supply chain can we determine the financial effects of thickness decisions.

Material cost per box. The cost of material per box is normally 15-30 percent higher between normal single-wall construction and the construction of two walls. Nonetheless, this expense must be evaluated against the possible rates of damage. When single-wall packaging causes 2 percent damage rates, and double-wall costs the same but keeps the damage rate at 0.2 percent, the extra cost of the additional packaging can usually be compensated by claims reduction and customer satisfaction rates.

Shipping cost implications: The cost of shipping depends on the thickness and mode of shipping. The 2 mm thickness addition may add 15-20 percent to the package weight, but perhaps it may enable saving cushioning material, which may be offset in the net weight. The calculation of the dimensional weight effects should also be done, since the thicker the walls, the less the inside space.

Labor and handling costs. Packaging thickness may influence labor and handling costs. The heavier and more robust boxes are easier to handle and to stac,k and might save labor expenses in the warehouse and also damage during the in-house handling. They also, however, take up more storage space and can be harder to break down to be recycled.

Long-term brand protection value Protective value of the brand in the long term needs to be considered in the cost calculations. Damage to products results in customer service costs, replacement costs, and possible long-term brand damage that significantly outweighs packaging savings. Investment in the right thickness of packaging to sustain the quality of customer experience is of particular advantage to premium brands.

The best thickness is usually found on the calculation of total cost per product delivered and not on the packaging materials costs. You should add material, delivery rates, damage fees, and customer care expenses to your analysis.

Sustainability & Environmental Considerations

Sustainable thickness decisions are also ethical and economically beneficial, as the concept of environmental responsibility is becoming a major factor to be considered in packaging decisions.

Recycled content availability. Availability of recycled content is dependent on the thickness and type of boards. A lot of the corrugated manufacturers provide boards with recycled contents of 70-100 percent, but this may decrease the strength a bit. The more recycled content is used in the boards with a smaller thickness, the more likely the board is to perform well and thus be more sustainable, even though more material is required.

Recyclability factors. The considerations of recyclability occur more with factors of adhesives, inks, and coatings rather than with thickness. Nevertheless, boards that have several components and are thicker may become harder to recycle at the facilities. Single-material construction can usually be recycled much more easily than a complex multi-layer structure.

Carbon footprint considerations: The carbon footprint should be evaluated by considering both the use of materials and the efficiency of protection. The packaging with 20% extra material could save the product damage that will result from the manufacturing and delivery of replacement products, and may be less harmful to the environment.

Sustainable sourcing certifications. There are sustainable sourcing standards such as FSC (Forest Stewardship Council), which guarantee responsible forestry practices irrespective of the thickness. In selecting boards that are thicker in protection, it is important to consider certified sources of sustainability so as to reduce the effects on the environment.

End-of-life considerations must have a bearing on the thickness decision. Heavier boards may serve as justification to the extent that they could be reused to provide secondary packaging or storage purposes and make the material useful beyond the initial packaging.

Maximizing protection efficiency based on the optimal thickness as the most sustainable solution, rather than minimizing the material use, can be more advantageous to the environment since environmental benefits are usually gained through preventing product damage, rather than the marginal material savings.

Practical Tips & Best Practices

To make effective use of cardboard thickness selection, it is necessary to have practical experience in the field of measurement, testing, and supplier control.

Accurate measurement techniques. Good methods of measurement begin with good equipment. A good caliper/micrometer with the ability to measure both compressed and uncompressed thickness should be invested in. Measure the board in several locations and record the variation because the manufacturing tolerances may vary. Always measure the uncompressed thickness of corrugated materials to have an idea of the actual cushioning characteristics.

Sample testing protocols. There should be sample testing procedures whereby the real shipping conditions would be simulated before undertaking large orders. Perform drop tests at different heights and angles, pile loaded boxes to test edge crush strength, and expose samples to the anticipated level of humidity. Determine failure points of documents and make thickness specifications.

Supplier evaluation criteria. The criteria in the evaluation of suppliers should incorporate the tolerances of the thickness. Trustworthy suppliers have a variation of thickness within the +-5% specifications. Ask for certificates of compliance and take into account suppliers with a guarantee of thickness. Form alliances with various suppliers to stabilize and provide competitive prices.

Storage and handling practices. The policies of storage and handling have a considerable impact on performance. Keep stored cardboard in a dry environment with a constant temperature and humidity. Corrugated materials should never be compressed when they are stored because the cushioning properties of corrugated materials are permanently destroyed. Turn over inventory to avoid the degradation of long-term storage.

Quality control procedures. The process of quality control must involve inspection of incoming materials. Sample incoming shipments randomly and measure thickness specifications and visual quality. Set rejection standards and make sure that they are clearly communicated to suppliers. Offering statistical process control as an option in case the volumes are worth the investment.

Documentation and tracking systems can be optimized by the use of documentation and tracking systems. Record damage by type of thickness, track customer response, and view the overall cost of packaging with damage claim. This information allows one to keep on improving thickness specifications.

FAQ Section

How thick is the average cardboard? The corrugated shipping boxes that are considered standard are 3-4 mm (C-flute), whereas retail packaging paperboard is between 0.3 and 0.7 mm. But again, average is all relative to use—packaging of cosmetics, crates of heavy machinery, and food containers need vastly different standards of thickness.

But is a board thick enough to be shipped internationally? Depending on the weight and fragility of the product, a minimum of 4 mm single-wall or 6 mm double-wall corrugated is normally used in international shipping. Include numerous processing steps, possible exposure to humidity, and increased throughput times. Test samples in your actual shipping routes before committing in large quantities.

Can cardboard boxes that are thick be recycled? Yes, the recyclability is not affected by the thickness, but it may be influenced by the complexity of the construction. The corrugated boards are simple to recycle, irrespective of their thickness. Structures that have plastic films, foil linings, or large amounts of adhesives cannot be easily recycled. Ask local recycling centers about particular guidelines.

What is the influence of board thickness on weight and shipping expenses? The extra millimeter of thickness usually increases the weight of packages 10-20%, depending on board construction. In the case of air freight, the extra mass literally adds up to expenses. In the case of ground shipping, dimensional weight will affect the size of the shipping package since the more a wall, the less interior volume a shipping package may have; thus, the outer size of a shipping package may increase.

Will it be possible to combine materials to achieve strength without being very expensive? Yes, the cost and performance can be optimized with the use of hybrid constructions with varying liner materials or flute combinations. Indicatively, recycled flute medium with virgin outer liners gives good strength at a moderate cost. Negotiate with the suppliers on the construction of custom forms to have a discussion on cost-effective ways.

Conclusion

The choice of a suitable cardboard thickness means the sacrifice between the demands in protection and the demands in cost and ecological impact, and brand presentation needs. The most preferable thickness is not the maximum-thickness part, as a specification that will provide adequate protection and is not expensive in terms of the overall supply chain cost and sustainability goals.

The success formula is to know what exactly you really need to do, carry out all tests on samples, and work with suppliers who are very knowledgeable and who can consult you on the choice of materials. By computing the present performance of your packaging, requesting sample boards of different weights, and experimenting with them in realistic and then committing to big ways. What kind of product is it that you are packing? Being aware of your special concerns can lead to the achievement of the most appropriate solution to the desired thickness.