Child-resistant vape packaging assumes that the whole box-system, outer structure, closure and internal restraints, are designed in such a way that the child younger than 52 months is not able to enter the vape product or its contents without a reasonable force whereas the adult possesses an opportunity to open the box-system. Practically, this extends well beyond the ability to place some sort of child-resistant label on it or a crude lock tab. Compliance actually depends on the way that the structural design, the engineering of the insert and the manufacturing tolerances merge to ensure that no chance access is made to any unit of that production line.

Child-resistant requirements are commonly an issue of labeling or single feature (such as a push-and-turn e-liquid bottle cap), depending on many brands. As a matter of fact, in the case of vape hardware, cartridges, and disposables, it is a complete structural and manufacturing challenge. Passing a limited number of samples in a test run is no guarantee of performance except when production is approached at scale, as slight variations in die-cutting, gluing or behavior of material can cause an otherwise passing test design to fail a regulatory spot-check, or even in practice.

Parent resistant Vapepackages manage structural design, insert engineering and consistency of manufacturing to minimize safety hazards and compliance breakdowns with time.

Why Child-Resistant Vape Packaging Is a Brand and Compliance Responsibility

Examples of direct brand liability problems include child-resistant packaging: failure to do this subjects the company to recall of its products, regulatory fines, electric injuries of accidental exposures, and the loss of retail shelf space.

The use of vape products is being subjected to more and more review by regulators and market places, as the chemicals in an item with nicotine have severe chances of poisoning a young child. Although a design may pass minimum legal testing during initial phases the manufacturing may be inconsistent leading to batch-level non-compliance, which causes an audit, shipment withholding, or the withdrawal of products forced out of the market. The loss of public trust is rapidly lost when an incident involving a shop hits the news, and retail partners tend to forget suppliers with inconsistent compliance records.

The compliance expectations are not met by the minimum legal terms but require performance under actual conditions of production which is repeatable and verifiable.

| Packaging Factor | Compliance & Brand Impact |

| Structural design | Determines resistance to unintended access; weak structures increase opening risk |

| Insert engineering | Controls product movement and exposure; loose fit can allow access despite outer closure |

| Opening mechanism | Influences child-resistance performance; overly complex adult access risks non-compliance |

| Manufacturing consistency | Affects repeat compliance across batches; tolerance drift often causes field failures |

Understanding What “Child-Resistant” Means in Vape Packaging

Child-resistant packaging is actually designed to ensure that children below 5 years of age find it challenging to enter a container or reach into it and injurious material in a reasonable time span, although the majority of adults should be able to handle it without any special equipment or extraordinary effort.

It contrasts sharply with tamper-evident features (that do not indicate if a package has already been opened) and safety labeling (which gives warnings but do not make the structure barrier to access). It also does not emphasize the aesthetics of ease of access or visual appeal but the practical challenge of access.

Test conditions Typically requiring compliance with ASTM D3475 standards, poison prevention packaging acts have test conditions that require failure to open the package by the entire test group (such as 4251 months) on the first attempt, and most costly on the second attempt after instructions are presented. Adult panels should have high rates of openability. Such needs compel design decisions to stifferness, tight fits, and secure closures as opposed to cosmetic ones.

| Term | Practical Meaning |

| Child-resistant | Designed to limit access by children through structural difficulty |

| Tamper-evident | Indicates prior opening (e.g., breakable seals), but does not prevent access |

| Safety labeling | Informational warnings only; no structural barrier to entry |

Packaging Structure Plays a Critical Role in Child Resistance

The advantage originates in rigid box structures over flexible pouches or soft cartons which are not very effective as far as child resistance is concerned in vape packaging. This extra rigidity and stability in dimensions complicate the ease with which small hands will bend or tear open the package.

Closure Systems – be they magnetic, tuck-end with concealed locks, push-slide systems, etc. have to be of a tight tolerance such that children can not use openings, or fail points. Domestic fit is also quite significant: when the product rattles or moves inside, it may make some leverage points that may decrease the overall resistance.

There are always trade-offs. Closures which are too restrictive will irritate the adult users (to the extent that they attempt to damage the package) and those which are too-loose in design will fall down. To achieve this sort of balance, there should be be early prototyping in the form of real products and, crucially, testing.

For brands seeking structurally sound custom vape packaging boxes, the solution is working early with manufacturers that have a feel of how these factors operate in large volume production.

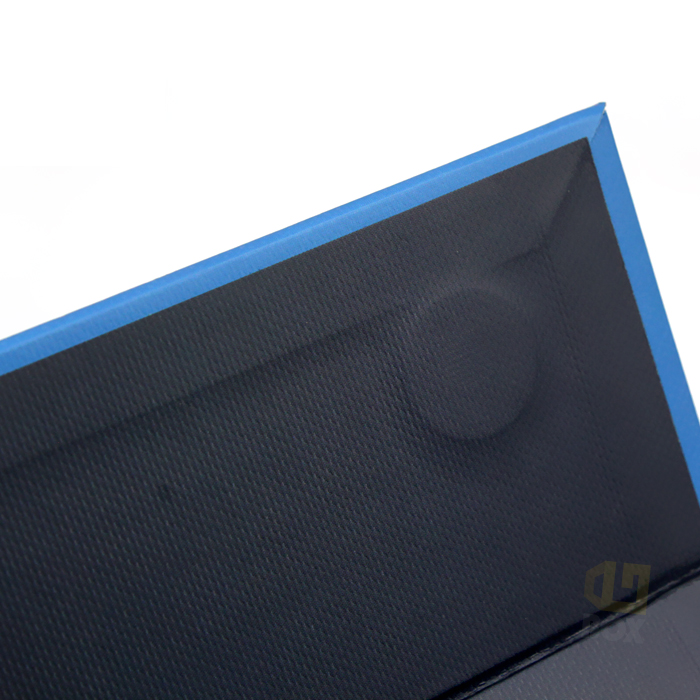

The Role of Inserts in Preventing Accidental Access

The role of the child-resistant performance in precision-engineered inserts is perhaps unsung. Inserts hold vape cartridges, devices, or pods firmly, preventing their movement, which, otherwise, would allow access through flexing, prying, or part-opening.

Low tolerance to insert even a millimeter may form play giving access to kids to the contents or to a weak point on the outer structure. Close, repeated fit minimizes this risk to a great extent and assists the entire package to withstand repetitive opening/closing actions without becoming damaged.

Also connected with the sustainability and cost goals is the insert choice although compliance should be the first priority.

| Insert Type | Typical Use Case | Compliance Contribution |

| EVA | Vape cartridges | Firm positioning; minimal movement |

| Foam | Lightweight devices | Cost-effective restraint; good shock absorption |

| Paperboard | Sustainable packaging | Controlled access; recyclable option |

| Molded pulp | Eco-focused brands | Structural containment; biodegradable |

Materials and Finishing Considerations for Child-Resistant Packaging

The stiffness of materials has a direct relationship with the ability of the package to withstand the small hands. The required rigidity is afforded with the help of less flexible paperboard grades (1200-1800gsm rigid board) and the thinner folding cartons might need extra reinforcement to reach the same resistance.

Sequestrations and layers influence strength and traction. A soft-touch lamination enables adults to handle it without it being too slippy such that kids find it difficult to hold on and pull. Matte finish eliminates the risk of reflective slips as opposed to glossy. Poorly applied or unstable coating may however crack, peel or wear out with repeated testing or shipping creating points of failure.

Material consistency in sourcing and application cannot be bargained upon at all – even minor change in caliper of the board or adhesion of the lamination can make the whole batch fail re-test.

| Material / Finish | Functional Impact |

| Thick paperboard | Improves resistance to prying and deformation |

| Soft-touch lamination | Enhances grip control; reduces accidental slip |

| Matte lamination | Reduces slip risk; maintains professional appearance |

| Unstable coatings | Potential failure risk from cracking or delamination |

Manufacturing Consistency Is Where Compliance Often Breaks Down

A well tested prototype may malfunction in the production environment when the processes of production are not well regulated. Changes due to die-cutting, adhesion, or small changes in tolerances in the insert molding can add up to thousands of units and make a successful sample inventory non-conforming.

A first certification test demonstrates that the design idea works in ideal conditions, even though it does not demonstrate that the factory is capable of reproducing the idea in a continual manner. This needs written process control, in-line quality control (measuring the closure force, insert fit, and dimensional fit) and periodic re-check testing on production samples.

Companies that do not take this step are usually the most surprised by it the most: having to recall, rework, or recall products after the fact.

Common Mistakes Brands Make With Child-Resistant Vape Packaging

- Incorporating with a label requirement of child resistance instead of a complete structural system.

- Not taking into consideration insert tolerances and thinking that outer closure suffices.

- Making decisions about packaging choice either on the basis of appearance or the basis of cost and not to consider if the performance in compliance during production conditions.

- And excessively relying upon sample approval and not requiring evidence of process stability and batch-to-batch consistency.

- One misses the consideration of the degradation of performance with time due to shipping, storage and repeated handling.

Conclusion — Child-Resistant Packaging Requires Structural and Manufacturing Discipline

Child-resistant vape packaging is not a special add-on feature of a certification stamp it is an internally organized system. Quality outcomes are due to knowledgeable structural decisions, accurate insert-engineered, restrained material and tolerance, and controlled production that delivers uniform processing with each production run.

Such an approach to it by brands reduces long-term compliance risk, safeguards the interests of the public and eliminates the downstream cost of failures. Whereas facade compliance is associated with the surface aspects of conformity, the variations between facade-compliance and genuine, abatible safety are found in the notion that packaging is the engineered product as it is.