Every jewelry brand is under pressure to deal with costs, and the initial years before gaining momentum these costs can make or break it. The place that can easily seem to cut costs is packaging, which is not the jewel itself, as you know.

However, this is the truth of a person who has witnessed thousands of boxes leave off production lines: jewelry packaging is not a box. The first physical point of your brand. Being inexpensive or of low quality just eats away at the perception of your customer on the quality of your work, your worth and dependability in the craft that you produce.

Packaging Is a Direct Extension of Brand Value

The buying of jewels is hardly ever fundamentally logical, its acquisitions are personal, symbolic, perhaps eventual. Emotional stage is defined by the packaging. Those magic can be killed earlier than even the lid can be opened by a poor or patchy box.

Quality is viewed holistically by the customers. When the packaging lacks quality, then the jewelry within it instantly becomes devalued. Examples in practice that we have seen in factories and customer comments reveal these general changes of perception:

| Packaging Quality Signal | Customer Interpretation |

| Thin or flexible boxes | Cost-cutting mindset |

| Poor insert fit | Lack of attention to detail |

| Inconsistent finishes | Weak brand control |

| Visible defects or scuffs | Low manufacturing standards |

Minor details such as a lid that does not fit correctly can make the buyers doubt reality or effort of the preparation.

The Unboxing Moment: First Impressions Stick Forever

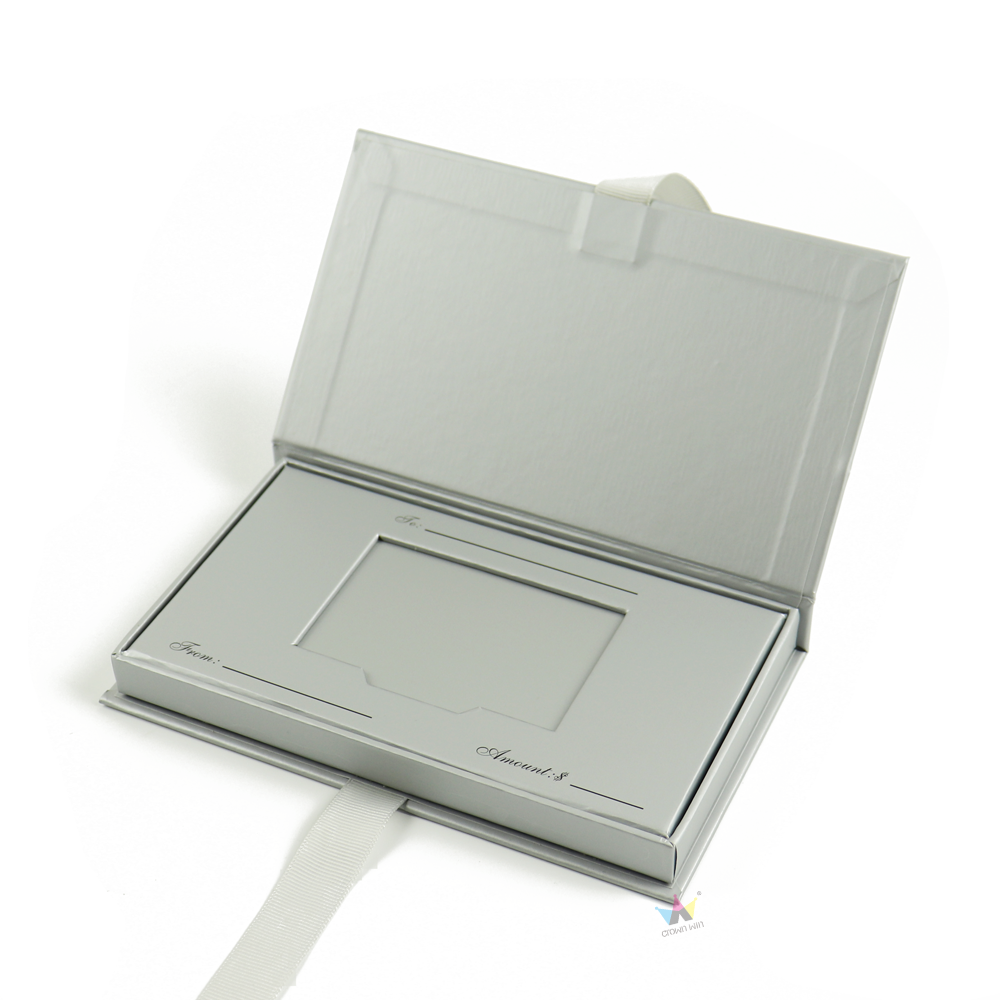

The unboxing experience has evolved into a mini social media affair to most customers. The response of a satisfying click of a magnetic closure or the gentle touch of a good lamination creates the excitement. In case of cheap jewelry packing, one gets the reverse of the same; noisy jewelry parts, difficult opening or poor display. That is the point in which they give you a recommendation or just shift to your competitor in the future.

Cheap Packaging Often Sacrifices Structural Integrity

Among the most common manifestations of cost-cutting is in structure, which is one of the fastest. Dilute paperboard, little reinforcement or haste assembly could reduce the unit prices, yet it only generates real issues downstream.

We’ve seen this repeatedly:

- Box deformation during shipping – this is particularly uncomfortable in e-commerce brands when its packages pass long ways.

- Shaky or wiggly lids- annoying during the unboxing process either in-store or directly to the consumer.

- Poor security- scratched or messy jewelry will reach the customer.

These are not petty nuisances, but they become obvious evidences of the fact that they did not spare corners, which directly negatively affect your perception of the quality of your brand in general.

Inserts Are Commonly Downgraded in Cost-Driven Packaging

To reach aggressive price points, a high number of suppliers break to generic foam or paperboard inserts which do not fit particular types of jewelry. They work well on a snapshot picture but not in practice.

Common failures include:

- Jewelry moving or mangling on transit.

- Inserts that rub flat after being used once or twice.

- Bad fit that causes the pieces to appear twelve in twenty displays when opening the box.

In the case of brands that sell rings, necklaces or earrings, an intuitive fit is not a luxury, but a quality that becomes an important factor in luxury jewelry sale. Poor inserts will reduce even the quality high-end to something that will feel like mass production.

Finishing Inconsistency Is More Visible Than Expected

The last process is finishing which is the most important of all in the packaging of jewelry. Control is frequently compromised in cheap runs, the result of which is easily observable:

- Unaligned foil stamping that appears to be in a hurry.

- Inconsistency in depth of embossing in the same manufacturer.

- Focal UV or box-to-box variation lamination.

When it comes to luxury or middle-range jewelery the consumers desire sophistication. The existence of different finishes indicates poor quality control, and consumers think of unreliable brands.

Cheap Packaging Undermines Consistency Across Reorders

The brand image is created gradually by repetition. Low-cost suppliers often have issues with batches of materials, printer calibration or rigor of QC and each reorder appears a little different.

This lack of continuity in the visual in wholesale in both the jewelry collections of jewelry releases that have a drop every six months or on the release of a themed drop. Customers notice. Retail partners notice. And when the points of recognition are compromised, it becomes much more expensive to revive than to consider dependable custom campaigns to package the jewels in the first place.

Short-Term Savings Can Lead to Long-Term Brand Costs

The mathematics appears so easy: reduced unit cost = improved margins. But there are secret costs accruing:

- Greater returns because of damaged arrivals.

- Hour and money wasted on repackage or apologizing.

- Negative opinions of having to feel cheap or being disappointed when the box was opened.

- Repeat business and referrals lost.

It is also costly in terms of what it takes to earn trust again; once perception is lost, which would be more costly than selecting package partners who care about consistency and integrity.

How Brands Can Balance Cost Control and Brand Protection

You do not have to end up spending heavily on glamorous packaging just to cushion the impression. Well-informed decisions are affordable enough and yield comfort:

- Get structural performance and correct insert fit right the first time – these allow most damage complaints to be eliminated.

- Select finishes (uniform foil, even lamps) that are repeatable as opposed to eye catching ones that are not.

- Vet supplier on reorder and QC of reorder and not polished samples.

- Packaging: Think logistics Packaging must be hard enough to get through shipping, pretty enough to look good on the shelf.

The aim is the packaging which makes no noise in backing your brand promise each and every time.

Conclusion — Cheap Packaging Sends an Expensive Message

The jewelry packaging already speaks even before you see your piece. Inconsiderable options can often speak in quiet, saying, we have cut corners here, as well, and made the customer lose emotional interest in your brand.

The brands, which consider packaging as an investment and not a pure cost, develop stronger trust, more positive evaluations, and long-term development in jewelry markets saturated with similar ones. In our case of working with global customers, the brands, which survived over time, are those that do not allow cheap packaging to ruin all the rest of the establishment.

What do you consider as some of your current packaging challenges? Contribute to the observations–we are glad of any useful experience of the factory.