In inserts, jewelry packaging is known to be the small detail. However, they also make a key difference in the level of security of the pieces in place, their eloquence of presentation upon unboxing, and the quality of the experience as a whole. Even a well-crafted rigid box with a beautiful finish will fail disappointments as long as the insert allows objects to move, collapses with time, or does not appear as the result of close craftsmanship.

The three most popular types of insert materials are EVA, foam (usually of PU or PE types), and paperboard, which come with different advantages and disadvantages. The perfect option will be determined by the type of jewelry, the cost, mode of distribution (retail or e-commerce), and brand value and not necessarily first impressions or the initial price.

Why Insert Selection Is a Strategic Packaging Decision

Inserts are not only fillers but practical elements that determine the actual performance in the real world as well as perception.

Some of the main effects of inverting inserts on the packaging quality are:

Product Stability During Shipping

A safe fit eliminates markings, knots, or damage during movement – this is particularly important with e-commerce shipments where items go through many hands.

Visual Balance During Unboxing

Affectionate cutouts and uniformity of form makes that just right look that affluent buyers desire.

Long-Term Durability Across Repeated Use

Higher quality inserts will not compress, be deformed or worn out and will still give the experience of being used months later on a dresser.

Perceived Attention to Detail

High end hard, sharp elements are an indicator of precise engineering, and it is a worthwhile investment to build a brand personality and a premium price.

Whenever insert performance is in line with your brand promise, this creates a repeat purchase and positive reviews.

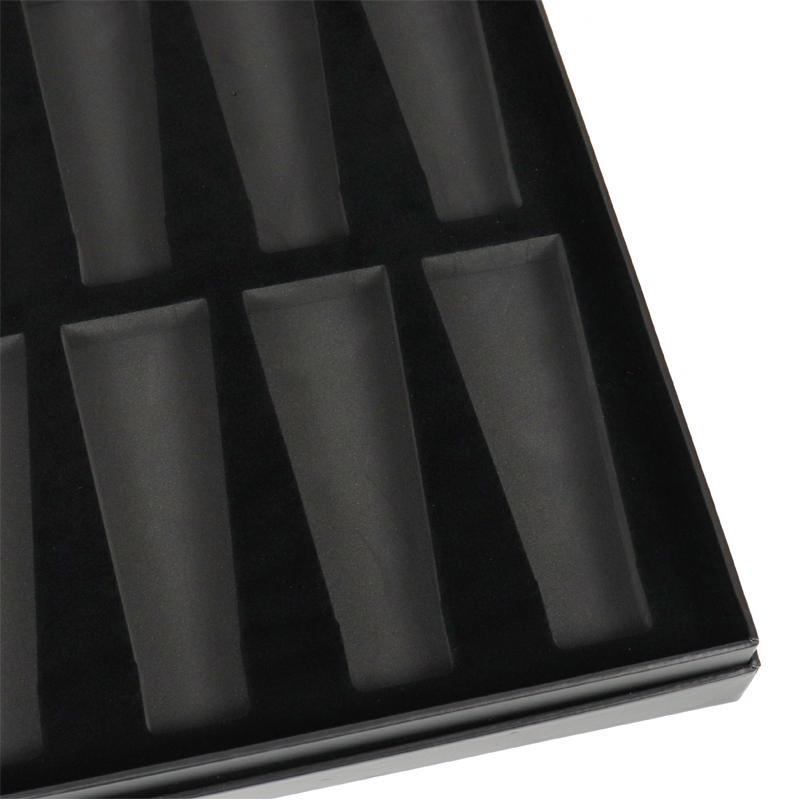

EVA Inserts: Firm Structure and High Protection

EVA (Ethylene Vinyl Acetate) inserts are brilliant in high-end jewelry packaging because of their solid, thick and dense appearance and their simple, neat appearance.

Best Suited For

- Rings, pendants and thin chains that have to be precisely placed.

- Valuables or weightier jewelry (e.g. statement necklaces or jewelries made of gemstones).

- Luxury brands were based around protection and constant premiums.

Key Advantages

- Better shape memory and compression strength- Shapes are formed even during repetitive openings.

- Outstanding batch to batch uniformity, appropriate to mass production.

- Flat surface which improves the perceived quality but does not flock fabric (but flocked versions provide classiness)

Drawbacks to Consider

The increased cost of material and accuracy in die-cutting means that EVA is ideal in medium-to-high end lines where protection counts.

EVA will be effective with brands shipping abroad, where shock protection during shipping cannot be compromised. At least in our case where we are producing thousands of customized jewelry boxes.

Foam Inserts: Cost Efficiency and Flexibility

After a sensible compromise between foam cushioning and cost, foam inserts (notably polyurethane / PU or polyethylene / PE) are common with jewelry of the middle market.

Best Suited For

- Easy to carry things such as earrings, small bracelets or necklaces that are stacked.

- Promotional lines or seasonal lines or price-sensitive lines.

- Products that require rapid customization without the need of heavy tooling.

Key Characteristics

- The shipping cost is lowered by lightness.

- Easy and tolerant to different forms.

- Some sort of cushioning to avoid scratches on the surface.

Practical Limitations

Reduced density implies an increased risk of indentation or deformation of time- time-varying storage or frequent handling. Not suitable to very high-value pieces whose long-term presentation is the most important.

Foam is also efficient in case of low budget but decent protection is needed.

Paperboard Inserts: Structured and Sustainable

Brands that value environmental responsibility, clean design, and integrate structure of rigid boxes prefer paperboard (or chipboard/cardboard derivatives).

Best Suited For

- Minimalist or contemporary line of jewelry.

- Sustainable brands that are interested in recyclable packaging.

- Less movement, less heavy pieces have less risk.

Key Benefits

- Recyclable in all aspects and corresponds to sustainability requirements (in particular, FSC-certified materials).

- Clearly defined and architectural appearance which augers well with high quality printing and finishing.

- Easy-to-fit with hard or magnetic boxes of closure.

Important Considerations

Uses professional die-cutting and structural engineering to avoid the tendency to bend or wear edges. Unforgiving of odd-shapes and heavy objects.

Crown Win regularly combines precision paperboard inserts with our own resilient box lines to offer an elegant and clean solution that fulfills the requirements of BSCI and SGS.

Comparing Insert Options Across Key Criteria

No single material wins every scenario—the right pick depends on balancing priorities.

| Criteria | EVA | Foam | Paperboard |

| Protection Level | High (excellent shock absorption) | Medium (good cushioning) | Medium (stable but less forgiving) |

| Shape Stability | Excellent (strong memory) | Moderate (prone to compression) | Good (with precise engineering) |

| Visual Precision | High (clean, tailored fit) | Moderate | High (crisp edges) |

| Cost Efficiency | Lower (premium material) | High | Moderate |

| Sustainability | Limited | Limited (petroleum-based) | High (recyclable/FSC options) |

| Best For Luxury Feel | Yes | Sometimes | Yes (minimalist brands) |

Test prototypes in actual situations, such as shipping tests, thermal tests, opening tests, etc. to test operation.

How Insert Choice Influences Premium Packaging Perception

Details are subconsciously perceived by customers. A solid EVA insert with a perfectly cradled ring would feel deliberate and luxurious; a lazy feeling may indicate that there are shortcuts, or the ring may appear to be actively sagging.

To spell consistency is the same thing as foil stamping or soft-touch lamination to brands that are planning to establish a long-term loyalty. It supports the idea that all the details were carefully considered.

Common Mistakes When Selecting Jewelry Box Inserts

To avoid emptiness on your packaging, avoid the following traps:

- Selecting based on surface and not on longevity.

- Using a single material in all SKUs (e.g., a heavy ring made of foam).

- Neglect of environmental conditions such as humidity or transportation pressure.

- Bypassing real-life testing except on some static samples.

Brands that test extensively via prototyping and discuss reviews with others experience less returns and more positive reviews.

Conclusion — The Best Insert Is the One That Supports Consistency

Finally, a good jewelry box should fit well protection, styliness, durability as well as brand concordance. EVA is good at a high level of protection, foam provides a handy flexibility, paperboard is good at providing a sustainable structure – each in its sphere.

When packaging is treated as a strategic decision (not an afterthought) the jewelry brands can design a packaging that has to work reliably during its manufacture to customer and be scalable with growth.

If you’re developing luxury jewelry packaging boxes and want guidance on insert materials tailored to your collection, our in-house team at Crown Win—and your collection requires unique packaging, our in-house staff at Crown Win has complete authority over the design, die-cutting, assembly, and quality control, which can be used to develop and test new and adaptable options to suit your vision.

This is a post that can go on WordPress/CMS. Please tell me whether you would wish picture suggestions (e.g. close-ups of each type of insert), or length/tone adjustments, or what article/page to follow!