One of the most typical structural-decades that can occur in the creation of a jewelry brand in terms of packaging lies in the option of a rigid box and a magnetic box. Although the two are largely utilized, they are applied in different applications and they do not fare well in terms of durability, costs, user experience and long term consistency.

It is a decision that many brands base on appearance since it is assumed that magnetic boxes are more premium. Practically, it is the more appropriate selection based on the position of the brand, product idiom, logistics specifications and the functions the packaging will perform in the retail and electronic commerce platforms.

Understanding the Core Structural Differences

Magnetic boxes and rigid boxes are similar to each other in being constructed of a similar base made of thick greyboard or chipboard and enveloped with premium speciality paper, frequently custom printed, foil stamped or overlayered with soft-touch lamination. The actual breakage is in the opening mechanism.

How Rigid Boxes Open and Close

Rigid containers are commonly full of lift-off lid (two-piece design) or telescoping. No moving mechanism, no magnets–merely a snug fit through fine tolerances.

How Magnetic Boxes Work

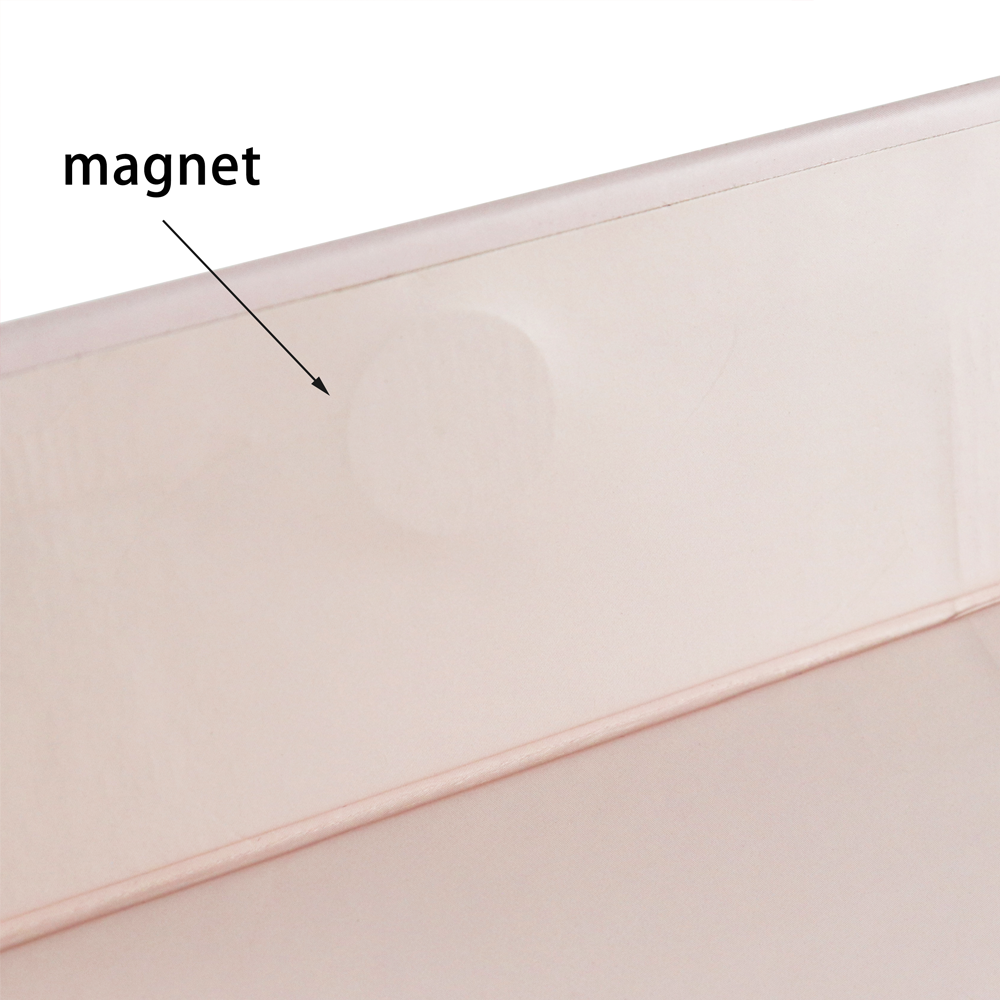

Magnetic boxes have a hinged top with concealed neodymium magnets in the flap and the bottom. This gives it that pleasing close snap and a book inaugurating feeling.

Quick Comparison Table

| Feature | Rigid Box | Magnetic Box |

| Opening method | Lift-off or telescoping | Hinged with magnetic closure |

| Structural complexity | Simple | More complex |

| Assembly requirements | Lower | Higher (magnet placement critical) |

| Long-term durability | Very stable | Depends on magnet alignment & strength |

These variations are felt in all aspects of the factory production to the unboxing of customer shipments and customer shipping performance.

When Rigid Boxes Are the Better Choice

Rigid boxes are shiners when structural reliability, cost-effectiveness and reproducibility are significant factors. This design is less complex; therefore, they have fewer failure points; they do not have hinges that may fatigue, magnets that may misalign each time the case is opened.

Rigid boxes have proven to be dependable in jewelry brands that operate high volumes or whose delivery method is through e-commerce. They are arranged neatly on pallets, they are more resistant to crushing during transportation and they can withstand some changes in production without functional problems.

Rigid boxes are good with:

- Delicate little rings, earrings, small things.

- Batch production ( 5000 or more units).

- Brands which focus on durability and supply-chain reliability rather than on theatrical openings.

In our plant we have observed strict constructions withstand perfect through several trips with carton ships across the oceans and at the same time stay 20-35% cheaper than the carton versions with magnet installation.

When Magnetic Boxes Make More Sense

Magnetic boxes are good in manufacturing a quality unboxing experience. Its hinge is slow and purposeful, mysterious XXI Century, and that magnetic shut closure is crisp and luxury-laden- step it up all to the perceived value on the necklaces or bracelets it is retailed as a gift.

With that said, they require even stricter tolerances: the magnet strength should also be equal (weakness results in the lid popping; too strong would make it difficult to open), the alignment should be accurate, and the hinge area would require reinforcement to avoid wear.

Brands are inclined on magnetic boxes when:

- Packaging is a second experience of the brand (e.g., luxury or ceremonial collections).

- Main channel of selling is gifting or boutique sales.

- The volumes of orders are also smaller (less than 2000 units), which explains the ordeal incurred per unit.

Comparing Cost, Consistency, and Scalability

The cost is not only about materials, it touches upon labor, parts, and QC.

Key Cost & Production Factors

| Consideration | Rigid Box | Magnetic Box |

| Unit cost | Lower | Higher (magnets + extra labor) |

| Assembly labor | Minimal | Moderate to high |

| Production consistency | High | Requires tighter control |

| Scalability | Excellent | More challenging |

Where infrequent reorders or frequent growth are involved, rigid boxes represent a consistent lead time and a reduced number of QC rejects. Magnetic boxes are scalable however, only under the understanding that they require trained in-house operators who have perfected the art of embedding magnets and reinforcing hinges- that which we end on end at Crown Win.

Durability and Real-World Logistics Performance

The packaging of jewelry must be able to survive over a single opening. It has in front of it warehouses, couriers, customs, and impatient customers.

The rigid boxes tend to be the most successful in compression strength and integrity in the long run. Their stacking pressure can be manipulated without degree of denting in their solid walls and there are no moving parts, so they do not require hinge fatigue.

Magnetic boxes are beautiful but may have a problem: the loosening of magnets with time (particularly when close to heat or frequent use), and hinge swelling, or misaligning lids when built incorrectly. In the case of e-commerce jewelry brands, we have identified that the tough options will decrease the claims of damages significantly.

Whenever giving order to custom jewelry boxes, it is always best to test samples in actual logistics, rather than when in the showroom lighting.

Brand Positioning and Customer Perception

Neither of the structures is more premium per se. The one on the right supports your brand story.

Slim or modern lines of jewelry tend to suit the utilitarian texture of hard boxes. The luxury, heirloom or gift-oriented collections have the advantage of the magnetic division of a close as a ritual.

It doesn’t count as much as consistency: when the packaging does not match, the trust can be broken quicker than any functionality can impress.

Common Misconceptions About Box Structure

A few myths still steer decisions the wrong way:

- Magnetic boxes are never cheap enough → Not in case the magnet malfunctions on the third opening.

- Solid-case boxes look old-fashioned → Solid case boxes are current with the use of contemporary finishes such as matte lamination or embossing.

- Customers are more interested in opening experience than in durability → They will not forget packaging failure (broken lids, popped opens) as long as they have them.

- The differences in structure do not affect the long-run quality of it, – they do, particularly when it comes to international shipping.

Conclusion — The Better Box Is the One That Fits Your Brand Strategy

No one is a universal jewelery packaging box winner, between rigid and magnetic boxes. Premium positioning is offered by delivering memorable unboxing experience through magnetic versions and extreme stability through rigid boxes at an affordable cost and scalable to containing growing brands.

The best bet is the middle ground; between the visual appeal and the manufacturing reality; one that makes your packaging work through the production floor and finally in the hands of the customer. When you are ready to enjoy the opportunities to make a choice according to your jewelry line, contact us to get samples of both structures.