Most cosmetic manufacturers spend a lot of money on high quality outer boxes only to realize that the products are delivered to customers in poor condition, moved or misplaced during delivery. Practically, this is a usual point of packaging failure.

In cosmetic packaging, the insert material offers more security to the product than the outer box.

The inserts are important in safeguarding the cosmetic products during handling, storage, and transportation.

Technically, as an engineer, the box has little to do with the shock absorption work it does; instead, the insert causes the product to vibrate less and to move less. The decision of the appropriate insert material is hence a practical choice rather than a cosmetic one.

The correct choice of the right insert material is dictated by the fragility of the product, weight, presentation requirement and distribution channels and not by cost.

Why Inserts Matter in Cosmetic Packaging

The stability of the product and the risk of its damage are directly influenced by the cosmetic packaging.

Although the outer boxes offer structure and branding, the inserts do three important functions that can have a direct influence on product integrity.

Product Protection

Inserts guard internal movement, absorb impact and limits stress on the weak components like glass bottles, droppers, pumps and pressed powders.

Visual Presentation

A shaped insert holds the products standing upright, centered, and aligned and this strengthens perceived quality and professionalism, which is vital in high quality cosmetic packaging formats such as rigid boxes and gift sets.

Unboxing Stability

In unboxing, the inserts keep the products safe and presentable with no loose parts or mis-fits that may reflect negatively on the brand, however appealing the outer packaging may be.

The use of inserts within the system of overall custom cosmetic packaging boxes is both a functional extension custom cosmetic packaging boxes system rather than an optional add-on.

Understanding Different Insert Materials

The individual cosmetic packaging inserts materials have a specific protective and structural use.

EVA foam, sponge and paperboard are the three most popular materials which vary largely in performance, cost, sustainability and their applicability.

EVA Foam Inserts

EVA (ethylene-vinyl acetate) foam is a closed-cell, densely packed foam that is known to have high shock absorption and precision cutting.

Sponge Inserts

The softer and more compressible cushioning materials are the sponges inserts that accommodate the slight changes in its dimensions.

Paperboard Inserts

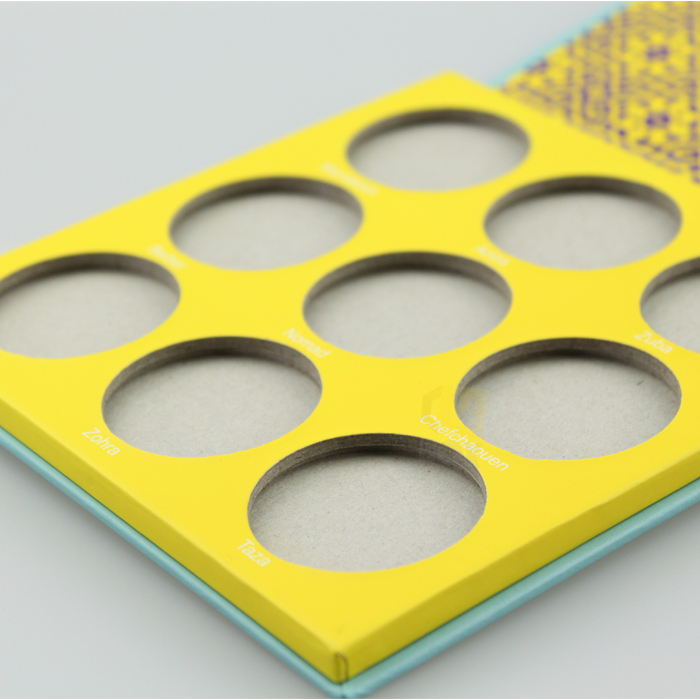

Paperboard inserts consist of die-cut structural elements which are designed to support products by folds, slot and geometry, as opposed to cushioning.

These differences would be critical to comprehend when developing cosmetic packaging that would work uniformly across all channels of distribution.

EVA Inserts — Maximum Protection for Fragile Cosmetics

EVA inserts offer the maximum protection on delicate cosmetic products.

Engineer-wise, the EVA foam is the safest insert material that can be used in cosmetics.

Shock Absorption

EVA is an appropriate material to use in glass bottle, ampoule, and luxurious fragrance packaging because it easily absorbs the impact energy during drops, vibration, and handling.

Precision Cutouts

CNC or die-cut EVA inserts can be cut accurately to the size of the product, reducing movement, and eliminating rotational stress of closures and pumps.

Best Use Cases

Cosmetic packaging EVAs are most suitable with:

- Glass skincare bottles

- Perfume bottles

- High-value serums

- Export shipping or long distance shipping.

- High-end hardboard boxing.

The trade-off is cost and recyclability which needs to be taken into consideration together with the needs of protection.

Sponge Inserts — Flexible and Cost-Effective Cushioning

Sponge inserts have moderate protection and are more flexible and cheaper.

The sponges inserts are most usually applied in cases where the products demand cushioning but not rigid positions.

Soft Protection

The compressibility of sponge inserts enables them to absorb minor impacts and absorb minor dimensional differences between production batches.

Adaptability

Multi-product kit Sponge inserts can be readily adapted to a multi-product kit or changing SKU without redesigning the entire package structure.

Limitations

However, sponge inserts:

- Offer lower levels of positional stability compared to EVA.

- Can compress over time

- May: product can be moved about in repetitive handling.

Use Cosmetic boxes Sponge inserts. Cosmetic boxes should be lightweight plastic containers or secondary protection layers, and not primary packaging which is fragile.

Paperboard Inserts — Structural Support and Sustainability

Paperboard inserts are less cushioning oriented and more structure oriented and sustainable.

Paperboard inserts do not use compression unlike foam-based materials and instead use engineered folds and cutouts.

Custom Die-Cut Designs

Geometry can be used to create cradles in the shape of paperboard which is effective in uniform product forms like jar, compact, and tube.

Recyclability

Paperboard inserts due to their fibrous nature match the principles of sustainability and blend in with the overall sustainable cosmetic packaging strategies.

Visual Integration

Paperboard inserts can be printed or color-matched with the outer box, which makes the whole visual experience consistent and helps to tell the brand stories.

Nevertheless, paperboard inserts provide little shock absorption and only suit controlled retail settings or lower fragility products.

Comparing EVA, Sponge, and Paperboard Inserts

There is no universal great insert material that can be used in cosmetic packaging.

In terms of comparative engineering:

- Protection level: EVA > Sponge > Paperboard

- Cost considerations: Paperboard < Sponge < EVA

- Sustainability impact: Paperboard > Sponge > EVA

The choice of cosmetic packaging insert material should be balanced in protection needs, budget, brand positioning and sustainability. Insert choice must also fit in the outer packaging structure be it rigid boxes or folding cartons as in larger packaging architecture comparisons of rigid boxes vs folding cartons.

How to Choose the Right Insert for Your Cosmetic Product

The selection should be prompted by the risk of the product rather than the taste.

There are a number of practical considerations on how to make decisions.

Product Weight and Fragility

The heavier or delicate products require more shock absorbing materials whereas the light ones might only need the support to be more structural.

Channel Requirements

E-commerce distribution subjects packaging to additional points of handling and drop risk in comparison with retail. Shipment inserts needed in DTC shipments must hence be superior to those made to display in shelves.

Brand Positioning

The cost of inserts used by luxury brands is often justified by higher presentation and perceived value and cost efficiency and recyclability may be important in mass-market brands.

Some innuendos should also be considered such as cosmetic packaging costs and the introduction of choices, which are not subject to any functional value.

Common Insert Mistakes Cosmetic Brands Make

Most of the failures of the cosmetic packaging were due to wrong assumptions on the insert.

Over-Protection

Replacing paperboard with EVA inserts where it is not needed and does not enhance performance is more costly and environmentally harmful.

Ignoring Sustainability

Foam-heavy inserts may be contradictory with sustainability claims, unless they are considered in the context of a complete material lifecycle.

Poor Fit and Movement

Poorly sized or inconsistently cut inserts permit flow of the products and therefore the use of the inserts is futile.

To prevent such errors it is important to treat inserts as an engineered component rather than a decorative element.

Conclusion — Inserts Should Support Both Protection and Brand Experience

Insert choice is a compromise between engineering delivery and brand purpose.

Good cosmetic packaging inserts ensure product protection, presentations and fit in the realities of distribution without unneeded complexity.

The correct cosmetic packaging insert has the right balance of protection, presentation, and being practical.

Brands that base inserts on product risk, channel exposure and system level packaging design will always minimize the rate of damage whilst preserving brand integrity.