Introduction

Many-layered packages, Corrugated cardboard packages, Packages made of cardboard layers with a fluted (wavy) layer between, Corrugated cardboard packages are many-layered packages made of flat cardboard. This innovative packaging technique becomes a lightweight and extremely strong packaging solution, which is the foundation of the modern packaging and shipping business.

It is impossible to overestimate the role of corrugated boxes in any shipping and packaging process. They are the most favored ship to carry the stuff of the world up from large e-commerce packages to large industrial goods. They are also elastic and can therefore be used in wrapping fragile electronics and heavy equipment when transporting them.

Corrugated boxes are associated with a huge number of benefits, that are why they are most favored by businesses all over the world. It made no bad work of the abrasion quality, and it conferred upon its products protection of the most immense kind, and, strangely enough, was not so heavy that they would have to ship much of it. Moreover, corrugated packages are easy to recycle, and are often made of recycled materials, another way to make it a sustainable package.

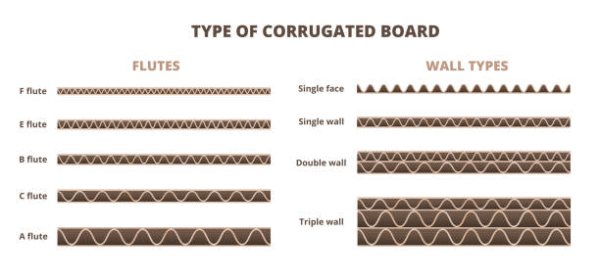

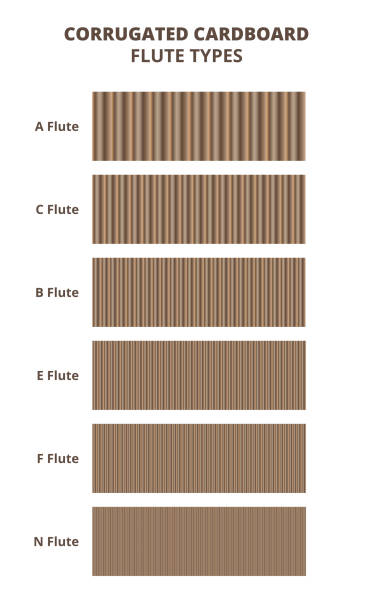

Corrugated Board Types (Flute Types)

Information about the different kinds of flutes is a significant component of the process of ensuring that you buy the corrugated box that best fits your needs. The benefits of each type of flute also vary and, therefore, can be used in various applications.

A-Flute has better cushioning capacity and stacking strength, which allows it to be used in wrapping fragile products that require maximum protection during transportation. The thick profile also offers the best shock absorption of its kind.

B-Flute can be printed more easily and offers hard and tight protection that can be credited to the smoother surface. This type of flute is geared towards use cases where structural stability requires quality graphics as a precondition.

C-Flute is the most commonly used form of a flute because it offers the best balance between the cushioning properties of an A-Flute and the strength of a B-Flute. It is also flexible to the extent that it can be utilized in many generic packaging applications.

E-Flute is slim and lightweight, which makes it to retail packaging jobs in which shelf appearance is mandated. It has a good flute design that makes it highly printable on quality point-of-sale exhibits.

F-Flute is the smallest profile available and thus best used when smaller-sized retail boxes, cosmetic packages, and space economy are important factors in a product, and still need a reasonable level of protection.

Double-wall corrugated (like BC or EB combinations) uses a combination of two types of flutes. It is an outstanding construction using relatively heavier products or goods that are relatively long in lengthy transportation routes.

Triple-wall corrugated makes use of triple triple-layer that provides maximum possible protective strength in heavy-duty use and extremely heavy products. This is a heavy-duty model that is robust enough to accommodate the toughest shipping/storing requirements.

Corrugated Box Styles

The variety of old-fashioned styles within reach is best and most precise fit when applied to a possible packaging requirement.

The box most commonly used is the Regular Slotted Container (RSC). This type of box has four equal-sided flaps that overlap the centre of the folder. The solution has a high cost-performance and can be adapted to most general packaging applications.

Half Slotted Container (HSC) – Half Slotted Container is like RSC except that, one fluid is not folded down, thus the container adopts the shape of a top-open container, this is most appropriate whenever the product to be loaded in is by overhead loading, or is in such a way that, the type of product loaded inside requires easy access during the filling process.

Full Overlap Container (FOL) – In this type of container, the flaps can overlap, which contributes to the strength of the container and protection. This type of style can be highly beneficial when the weight is too high or when the goods require additional protection during transportation.

One-Piece Folder (OPF) – is covering the product like a book, which is a new type of packaging used in books. This enables maximum material to be used to produce them lightweight and good to provide them with tight and secure protection.

Die-Cut Boxes – these are specifically cut packages that enable endless branding possibilities and can be tailored to provide specialized packaging solutions that address product protection requirements.

Telescoping Boxes – these are convenient and can be reused. This is the style that should be used on retail packages and gift boxes where the image is paramount.

Wrap-Around Blank – adheres as effectively as a folding carton and fits tightly around the product, giving it a clean, professional appearance with very little material usage.

Five Panel Folder (FPF) – is a combination of good protection (narrow-long format) and low-waste cost (material economy).

Full Telescope Design Style (FTD) – this style involves covering the entire bottom half with the cover and is most suitable for high-value/presentation products.

Corrugated Box Strength Ratings

The secret to selecting boxes that will adequately protect your products in transit is knowledge of the strength rating.

The Edge Crush Test is a measure of the corrugated board’s weight-bearing strength. The test is invaluable when it is used to predict how efficiently and effectively boxes will perform when stacked during storage and transportation.

Bursting Strength (Mullen Test) is the resistance of the material to burst under stress and the degree to which the box can survive during the shipping process, rough handling, impact, and compression trauma.

Box Compression Test (BCT) is a test of the maximum compressive strength of an intact box until it collapses perpendicular to the direction of the compressive action, or in other words, the most comprehensive test of the overall box strength and stacking capacity.

Applications by Box Type

Different kinds of corrugated boxes are good in various types of applications, and thus, they need to be well chosen so as to bring out the best in them.

E-commerce shipping requires RSC boxes of the appropriate ECT ratings to ensure that delicate products reach their destination without being subjected to unreasonably high delivery expenses. C-Flute construction is flexible and can be applied to most online retail uses.

The packaging of food and beverage businesses generally needs bespoke corrugated shapes that factor in moisture levels, regulations, and the freshness and integrity of the product.

Smaller E-Flute or F-Flute-based structures are used to package electronics hardware, providing the maximum possible branding flexibility and adequate protection to the delicate elements.

Threading and post attaching: Threading inserts and post attaching can be added to die-cut boxes and E-Flute without compromising structural strength to provide a higher graphics capability and shelf appearance.

The high industrial transport conditions and prolonged shelf life of industrial products require the strength and protection of triple-wall corrugate construction and large ECT ratings.

Sustainability of Corrugated Boxes

The leader in green packaging and healthy fielding is corrugated packaging.

The majority of the corrugated boxes are manufactured with high proportions of recycled content that use fewer virgin fibres and have minimal environmental impacts. It is a cyclic process of manufacturing the natural resource and maintaining the quality of products.

A corrugated box can be easily recycled, and most of the contained material can easily be recycled into packaging products. In addition, corrugated products are biodegradable; hence, they can easily break down on their own without leaving behind any pollutants in the environment.

Sustainable corrugated packaging fulfills extremely high eco-friendly requirements and standards to the extent that such businesses can attain their environmental objectives in the packaging systems and product protection, and branding capabilities.

Conclusion

Having this great variety of various types of corrugated boxes, there are really many factors to take into consideration all factors when choosing the type of corrugated box that you will be using. It is the fineness of the electronics, the equipment of the great scale industry, or the ornamentation of the points of sale with the beautiful displays, the productivity of the variety will ensure the maximum security, cost-effectiveness, and the contentment of the purchaser.

The corrugated packaging has been a favorable option in the list of businesses that seek secure packaging solutions that are also environmentally friendly due to the technological trend and renewed trend in corrugated packaging. All these complexities can also be exploited by the organizations to reap maximum benefits that the corrugated packaging presents to them to achieve a better brand image, as well as to ensure the security of their goods when they are in the process of the supply chain by liaising with the packaging companies, who understand all these complexities.