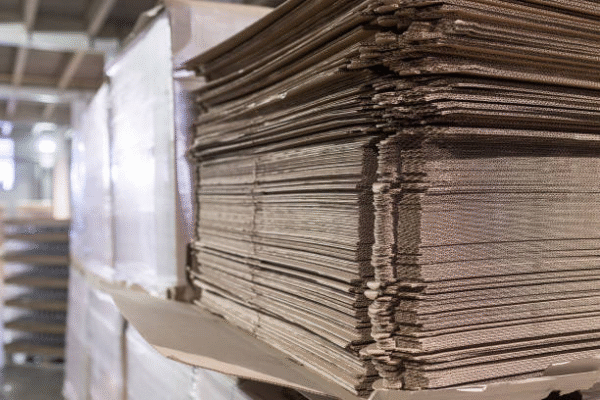

Introduction to Corrugated Boxes

These boxes, in the form of corrugated boxes, are the mainstay of the current shipping and packaging industry, which has been providing safe transportation of products made by manufacturers and reaching consumers everywhere in the globe. These flex-pack containers are designed with cardboard boxes that are built in a multi-layer fashion, which makes them both strong and lightweight, and also low-cost.

Whether your products arrive at your door as a result of e-commerce and they have been delivered to your door or whether you are shipping your products across the continents, the corrugated boxes are used in almost all industries. They save it all, not withstanding the frail electronic equipment and cosmetics or the enormous mining devices and foodstuffs. The combination of strength, low cost, and environmental friendliness in one package has made corrugated boxes the gold standard shipping containers in the packaging business.

Little need be said about the significance of corrugated boxes in the shipping and packaging sector. They have become the basis of global business since they help companies to deliver products efficiently at low costs and meet their sustainability objectives without any risk.

What Makes a Box “Corrugated”?

These are boxes made of corrugated material, which hence why the manufacturing of this kind is referred to as corrugated. Corrugated material: Two sheets of flat linerboard surround a wave-like layer called the middle, in between which is sandwiched a hollow sheet known as the corrugated material. This intelligent architecture is made of air columns to provide it with resistance cushioning and strength.

The construction is rather different from that of any regular cardboard or paperboard, which consists of a single layer of pressed paper fibres. Even though lightweight operations (cereal boxes or business cards) can be shipped with plain cardboard, corrugated material is superior in terms of protection and weight bearing, so it is reasonable to recommend corrugated shipping and storage facilities.

The corrugated form is that of a row of short pillars that separate the burden and give resistance to the proportions of pressure on all sides. It is an engineering principle that architecture borrowed and with it the simple materials available in the cheap paper production turn into very strength making packaging materials.

Components of Corrugated Boxes

It is not difficult to learn about the construction of corrugated boxes and to understand why these boxes possess such excellent performance characteristics. Any corrugated box consists of 3 significant components:

The fluting is used to construct the corrugation. It is the middle layer that has the look of a row of arches, which has given the corrugated boxes the strength that they are known for. The fluting has air spaces as shock absorbers, protecting the contents of the package without adding too much weight to the overall package.

The outer layers that are squashed one atop the other are referred to as linerboard. These slick surfaces provide the highest quality printing on the branding and shipping label and contribute to the structural integrity of the box. The main protection against moisture and the external contamination also is achieved with the help of linerboard.

The performance varies by combining the liners and fluting in various ways. The corrugated is single-faced (only a liner is exposed), or single-wall (the most common) corrugated has sandwiched fluting between liners. The additional layers of a PCB will be double and triple-walled to provide more strength and protection.

Types of Corrugated Board

The Boxes made of corrugated material are designed in various configurations to meet various functions and strength requirements:

Single Face corrugated, there are not many liners on any side of the fluted area, and the fluting is not covered. It is mostly used in wrapping and cushioning irregular objects in wrapping and cushioning rather than designing boxes.

The most common construction using corrugated is a single-wall wall whose single layer is fluted and uses 2 linerboards. It has an excellent strength-to-weight ratio and is highly competent in most common uses in shipping. Single-wall corrugated 3-4mm thick.

The construction of the Double wall consists of two layers of fluted construction, uses 3 linerboards, and produces significantly bigger boxes capable of transporting heavier goods or being sold with a higher shipping range. The additional ply provides additional puncture and load-carrying resistance.

Triple Wall corrugated is a corrugated formed sheet to achieve the maximum strength possible on the hardest applications, utilizing three fluted layers of four linerboards. They are bulky boxes that can carry very heavy goods and provide maximum protection during their long-distance transportation or storage.

They have all the advantages of a single wall for common shipping merchandise and double those advantages when a shipper requires the highest level of security and strength, and three times more advantages when a shipper requires the highest level of these advantages.

Corrugated Box Strength and Durability

A good example of structural design that offers superior strength benefits is corrugated boxes, where the user cannot afford not to utilize its shipping functionality. The fluted construction dissipates the load across its structure; thus, there is no local accumulation of stress that could cause system failure. This is an advantage of engineering that allows corrugated boxes to carry a significant amount of weight and still keep their shape without breaking anything to protect them.

The manufacturers would also have an opportunity to design the boxes to suit special protection and performance requirements. Edge crush strength, burst strength, and compression strength can be customized with material choice, flute size, and method of construction. These alterations also allow them to fit each box to the protection they are supposed to provide.

Corrugated boxes are good, crush-resistant, liquid penetration-resistant resistant and impact-resistant. An air-filled flute structure will absorb the shock energy, and the linerboard will provide a protective barrier against the elements in the environment. The modern corrugated can even perform the moisture-resistant treatment and ability to strengthen the capacity to add longevity.

Common Box Styles

It is hard to believe, but corrugated boxes come in a truly wide range of different styles: Each is specific to various products, and the packaging requirements of different shipping jobs.

The most common type of box is the Regular Slotted Container (RSC), or as it is commonly referred to is the box that has 4 flaps attached in the middle when folded. It is a flexible design that applies to the majority of products, and it is easy to make the products and assemble them.

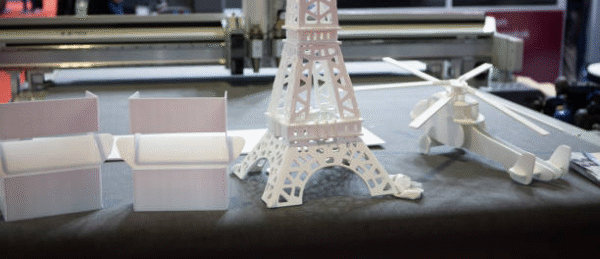

Die-cut boxes are highly accurate due to a special arrangement (or die) in which the preferred shapes and sizes are cut. The boxes will be used not only to provide structure and professional appearance but also to cover irregular goods.

The corrugated packaging market high end in the sense that the custom jobs are designed to suit a particular brand or piece of some other product requiring protection. These solutions can involve special closures, internal partitions, product view windows, and enhanced graphics, which can be utilized to present the brand as intended and in the most secure manner.

Each of the styles is used in terms of both functional and marketing needs, and in this way, the company is free to select the best of the three duties of protection, efficiency, and brand presentation as concerns its products.

Benefits of Corrugated Boxes

Incorporated boxes have a robust package of advantages, which have made the product the perfect package and shipping boxes to be deployed anywhere across the world.

The shipping with corrugated construction is of excellent weight and strength, and well worth it. This not only helps in saving the shipping cost, but also gives sufficient protection to the businesses because the weight that the boxes would cause to them is not much, and structural strength is at its optimum.

Corrugated boxes are ecologically friendly, sustainable, and highly recyclable. Some of the major constituents of these boxes are recycled materials, so recycled material can be used again after use, and this will create a closed-loop system, which will generate very little waste and also not non-harmful to the environment.

The low price is due to the efficient methods of production and the availability of raw materials, and also to the flat packs of boxes to ensure efficient storage and transportation. It is an economic advantage that provides the corrugated packaging with an opportunity that may be opened for businesses of all sizes.

High customizability allows one to create packaging that can serve its products and brand requirements at full scale. Corrugated boxes can be tailored to almost any need using size and shape, graphics, and other special features.

Eco-Friendliness and Sustainability

The most sustainable box is corrugated and thus a very good option for companies that practice sustainable operations. The corrugated materials can be recycled and biodegraded, hence the packages will not have a long-term waste problem.

Most of the corrugated packaging consists of renewable materials (mostly recycled paper fibre and sustainably grown forest products). The renewable foundation attempts to reduce the use of virgin material and responsibly manage woodland.

Companies relying on corrugated packaging can utilize environmentally friendly supply chains. To a certain extent, the efficiency of the corrugated recycling systems enables the reusing of boxes to be converted into new materials of wrapping materials in a time frame that is restricted and, by extension, reduces the environmental impact of shipping processes, in general.

The fact that corrugated boxes are light also promotes sustainability since it saves fuel during transportation. Light packaging will reduce shipping expenses and also carbon emissions, resulting in environmental advantages in the supply chain.

Conclusion

The combination of strengths, versatility, and environmental friendliness has definitely earned corrugated boxes the right of place as the number one preferred packaging solutions within virtually any industry. They are designed in such a way that they do all of that really well on the slow speed like the best electronics and really heavy industrial products too and a special liner in case of hazmat.

They can be helpful as a mere protection, but can be feasible to inbuilt advanced branding possibilities, full customization, and some possibilities to improve the safety of the product and the customer. Corrugated boxes can be modeled and designed to suit the size and business requirements, whether normal shipping container or elaborate custom containers.

The reason why corrugated packaging is a good competitor of the business and the targeted goals of the business is that corrugated packaging is an environmentally friendly material that can withstand this. Since the sustainability and cost-efficiency of the products utilized began to be valued as the business became technologically advanced and eco-friendly, it can be deemed that the utilization of the corrugated boxes is the most efficient method of balancing efficiency, cost-effectiveness, and environmental friendliness.

Due to its longevity, moldability, and sustainability, corrugated boxes can be referred to as a tested and proven technology, but which can nonetheless be innovated and improved. So immense are their natural strengths, economy, and nature that corrugated packaging will still retain its seat of business in the world in the coming decades.