Cardboard and Corrugated are the two most commonly used types of packaging material in business, and therefore, when deciding the type of material to use in your business, you must be well-informed of the difference between the two to make the right choice. People tend to use these terms haphazardly, but there is a basic distinction between the two concerning their properties and usage. This misconception usually leads to the choice of the wrong solution associated with packaging that will either lead to a complete decrease in the degree of product protection or to increased spending simultaneously.

This is because of the informal words, which can be misappropriated, like cardboard to mean any paper-based packaging material. However, you should pay attention to the peculiarities of each material and the way it is better utilized to decide which of the possible variants of packaging may best suit your purposes.

What is Cardboard?

Cardboard can be described as heavy paper stock, which is produced with the primary purpose of packaging heavy products that are not shipped as such. It is a one-ply material which is made up of heavy paper squashed into a tough sheet, and that is what makes it more acceptable as a retail packaging material, where the attractiveness of the material would be the most preferred aspect over the strength.

Common applications of cardboard include cereal packs, tissue packs, and greeting cards. It is also used in the production of the product package, e.g., cosmetics, medicines, and other consumer products, where the overriding requirement is not to shield what is being transported, but to display a brand as demanded.

These cardboard properties are important because it is light by nature, is unlayered, and provides light objects with their stability. However, its low-end character also suggests that cardboard is not strong and sturdy, i.e., it cannot endure high-stress operations like transporting or storing heavy products.

What is Corrugated?

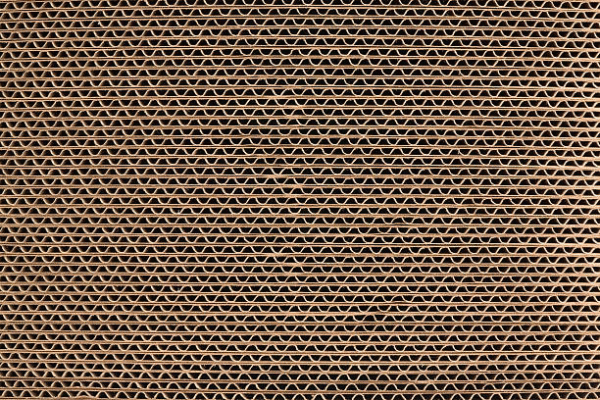

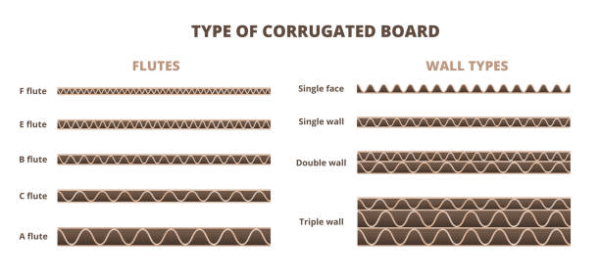

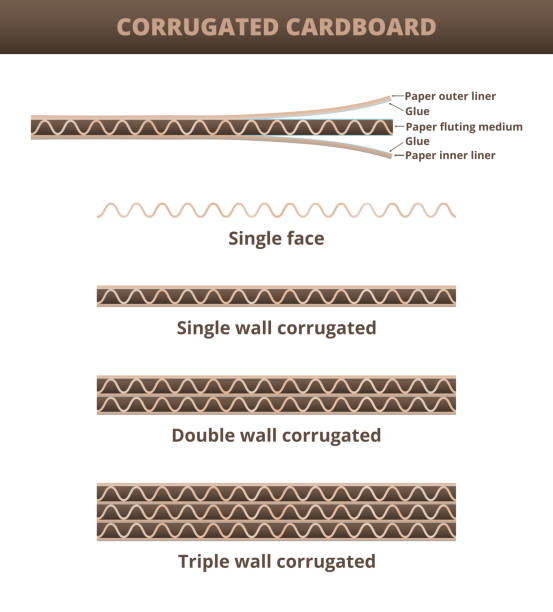

The superior type of packaging must be called corrugated material that is made so as to have three layers that are an inside liner, an outside liner, and the one in between the liners is the fluted medium. It is this unique kind of construction that creates the identifiable wavy effect when looking at the edge of a shipping box.

The fluted undercarriage has an extreme weight ratio-shock resistivity cushioning system. This type of three-layer construction is provided in many configurations; single-wall corrugated is one sheet of flute, two-sheet-flute is double wall, and three-sheet-flute is triple wall, which is the strongest and can support all applications.

Corrugated finds numerous applications, including protection and durability applications. All shipping and industry package products and e-commerce shipping require corrugated great strength. The compressive, impact, and moisture resistance strength of the material contribute to it being the material that cannot be done away with in the transportation of goods at a high cost and in the storage of such goods.

Key Differences Between Corrugated and Cardboard

Understanding that all materials are unique will enable one to understand when all and every alternative will be used:

Layers: A cardboard has only one layer, as compared to corrugated, which has many layers in the form of the famous fluted inner core, giving it structure.

Strength: Cardboard just provides background protection that is available only in lightweight products, but in the case of corrugated cardboard, it has an excellent impact protection and can support heavy or fragile products.

Common Retail Packaging Uses: This is the most generic use of cardboard, on which the main factor is appearance and shipping, storage, and heavy-duty uses, on which the corrugated should survive the trip and provide maximum protection.

Durability: Cardboard has low durability based on short-term use, but corrugated has high durability, especially on multiple handling, two and three-wall structures.

Customization: The cardboard can be customized to a minor degree, and the most widely used ones are the printing and simple-shape type, corrugated no restriction on the number of customization opportunities in the field of structure, both in customization and strength.

Why the Confusion Happens

The very common mistake of confusing cardboard and corrugated is based on the simple linguistic patterns of everyday living. The term is misused by the majority of people to represent any box-like construction, irrespective of its construction material or intended purpose.

This language downsizing is being done even with the boxes used in corrugated packaging, as the common man calls it, cardboard boxes. Although this informal language suffices in most informal situations, it lends itself to problems when a business must mention specific packaging specifications or when a supplier must know the definite material requirements.

Which One Should You Use?

Whether to use cardboard or corrugated is entirely based on what you need and what you want to do with the packaging you are considering.

In cases where decorative packaging should be more emphasized than protection, like in the event of producing a decorative package with low weight, cardboard packaging is the best packaging to use. Shipping cosmetics, retail goods, or other products that do not require much damage during the distribution process, cardboard can be a cost-efficient solution that lets you present your brand name in the most positive light.

Corrugated is highly required where you want to have security during shipping, stacking, and handling of the product as your primary concern. The box that is best to use is corrugated when you have to subject your products to the harsh environment presented by most modern logistics networks, such as e-commerce, manufacturing, exporting packages to other countries, or any other procedure where you have to transport your products using adequate materials to be able to endure the process.

Conclusion

As practice shows, a correct start of the conversation about packaging materials with specific terms will help you to identify the best variant that will meet your needs. Correlation can be a pain, but understanding where these various materials appear dissimilar in properties and applications can not only save you money but also give your products the appropriate protection.

Bright cardboard is what the business needs to be because corrugated is more robust, resistant to tears and breakage during the shipping and storage process than the generic word, cardboard. The choice of the material being used will not only directly impact customer satisfaction, product integrity, and, naturally, your bottom line.

These are the critical packaging choices that we can help businesses make at Crown Win Packaging with our long history of customized packaging options. Regardless of the weight rating, whether lightweight cardboard is needed to display the product in store or a more robust corrugated box is needed to ship the product around the world, our team will find the just-right material to complete its objective and commit itself to delivering quality and innovation to the design process of the package.